Electrodeposition of tin in presence of К<sub>2</sub>ТiО<sub>3</sub>

DOI:

https://doi.org/10.15421/081602Keywords:

tinning, potassium metatitanate, microcomposite materialAbstract

The abnormal influence of potassium metatitanate on the rate of the deposition of tin from stannate electrolyte is discussed: introduction of 1 mmol/L К2ТiО3 into working solution causes a fivefold increase of partial current

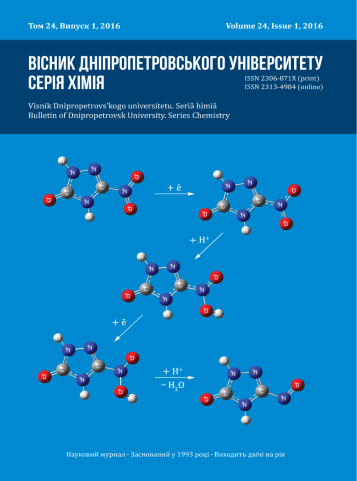

Sn(VI) → Sn0 and, respectively, the current output of tin. The analysis of the correlation of potentials' values which are installed during the process of electrodeposition of microcomposite material was carried out. The correctness between the potentials' values and sustainable forms of precipitated component at a specified pH value was determined. The possibility of formation the titanium hydride is shown in these conditions. A sharp change in morphology of the tin sediment surface in the presence of additive К2ТiО3 in the tinning electrolyte is reviewed. The single-phase nature of the obtained micro-composite material including tin and titanium is proved. To explain these facts a scheme of electrode process is proposed, whereby SnO32– and TiO32– ions are reduced with hydrogen at the cathode, where the product of metatitanate-ions reduction is titanium hydride which is capable of catalysing SnO32– reduction. The suggested scheme also explains the changes in the morphology of the sediment surface. The growth of the needle crystals of tin which segregate in the presence of TiO32– ions takes place on titanium hydride active centers.

References

Golovko, D. A., & Belyanovskaya, E. A. (1999). [Self-activation of a tin electrode modified by anodic treatment in an alkaline solution]. Voprosy khimii i khimicheskoi technologii – Issues of Chemistry and Chemical Technology, (1), 84–86 (in Russian).

Popov, V. S., Sevastynov, V. G., & Kuznetsov, N. T. (2012). [Synthesis of nanostructured SnO2 coatings through new volatile precursors by APCVD with induction heating]. Kompozyty y nanostruktury – Composites and Nanostructures, (1), 33–43 (in Russian).

Stepanov, А. Yu., Sotnikova, L. V., Vladimirov, А. А., Dyagilev, D. V., Larichev, T. A., Pugachev, V. M., & Titov, F. V. (2013). [Synthesis and research of photocatalytic properties of ТiО2-based materials]. Visn. KemGU – Bull. KemGU, 1(2(54)), 249–255 (in Russian).

Dobrosmislov, S. S., Kirko, V. I., Nagibin, G. E. & Popov, Z. I. (2014). Electronic Structure of SnO2 when Doped with Sb and V. J. of Siberian Federal Univ. Engineering & Technologies, 7(2), 146–153.

Vargalyuk, V. F., & Plyasovska, K. A. (2008). [The influence of the electrolysis mode on the properties of electrochemicallyformed anticorroding coatings on tin]. Visnyk Tehnichnogo universitetu «KhPI» – Bull. of technolog. Univ. «KhPI», (32), 123–128 (in Russian).

Plyasovska, K. A. (2013). [Electrochemical formation and properties of oxide films on tin]. Synopsis. Dnipropetrovsk National University, Dnipropetrovsk, Ukraine (in Ukrainian).

Vargalyuk, V. F., & Plyasovska, K. A. (2009). [Electrochemical formation of SnхTi(1-х)О2 oxide film on tin]. Visn. Dnipropetr. Univ.: Khim. – Bull. Dnipropetr. Univ.: Chem., 17(3/1), 42–45 (in Russian).

Vitkin, A. I., Galkin, D.P., & Berlin, B. I. (1978). [Fundamentals of the theory and technology of production of tinplate]. Moscow, USSR: Metallurgy (in Russian).

Marchenko, E. M. (1971). [Photometric determination of elements]. Moscow, USSR: Mir (in Russian).

Zakharov, A. M. (1990). [Phase diagrams of binary and triple systems]. Moscow, USSR: Metallurgy (in Russian).

Palazhenko O. (2012). [Pourbaix diagrams at elevated temperatures: a study of Zn and Sn]. Science University of Ontario Institute of Technology.

Wood, D. J. (1993). The Characterization of Particulate Debris Obtained from Failed Orthopedic Implants. Retrieved from http://www.engr.sjsu.edu/WofMatE/projects /srproject/

Luchinskiy, G. P. (1971). [Chemistry of titanium]. Moscow, USSR: Khimiya (in Russian).

Downloads

Published

Issue

Section

License

Copyright (c) 2016 Oles Honchar Dnipropetrovsk National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).