INFLUENCE OF POLYOXYPROPYLENETRIAMIN AND CONTENT OF OXIRANE RINGS ON PROPERTIES OF EPOXY-POLYSULFIDE COMPOSITES

DOI:

https://doi.org/10.15421/jchemtech.v30i4.260487Keywords:

epoxy resins; polysulfide rubber; a preliminary thioetherification reaction; polyoxypropylenetriamine; deformation-strength, adhesive and dynamic mechanical properties; epoxy group content.Abstract

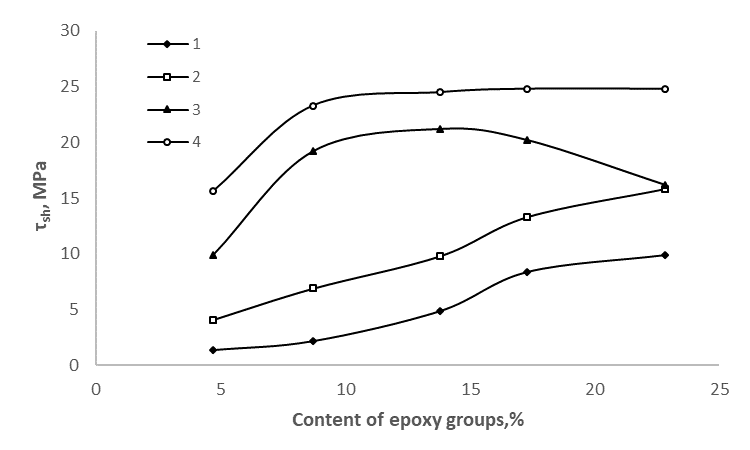

The possibilities of controlling the deformation-strength, adhesive and dynamic mechanical properties of epoxy-polysulfide composites based on the products of the preliminary thioetherification reaction (PRTE) with the help of small additions of polyoxypropylenetriamine and changing the concentration of oxirane cycles in the epoxy resin are determined. It has been established that the introduction of polyoxypropylenetriamine into compositions based on the products of the preliminary reaction of thioetherification of epoxy resin with liquid polysulfide rubber (thiokol) leads to an increase in adhesive and cohesive strength, strain at break, and the work of destruction of the material. The effect is achieved both by adding polyoxypropylenetriamine to a mixture of epoxy resin with liquid thiol during PRTE, and by using it as a co-hardener when curing PRTE with diethylenetriamine. It has been shown that the presence of polyoxypropylenetriamine in the PRTE product has a significant effect on the dynamic mechanical characteristics of the cured composition. The introduction of polyoxypropylenetriamine contributes to a noticeable increase in the dynamic modulus of elasticity in the region of the glassy state of the composite and the molecular weight of the chain section between the nodes of the chemical network, as well as the maximum value of the mechanical loss tangent and loss modulus. An extreme dependence of the adhesive shear strength of adhesive joints made using PRTE products on the content of epoxy groups in the resin has been revealed. The effect of strengthening adhesive joints due to modification with polysulfide rubber is most pronounced for epoxy resins, in which the content of oxirane cycles ranges from 8 to 15 %.

References

Shahrokhinia, A., Biswas, P., Reuther, J. F. (2021). Orthogonal synthesis and modification of polymer materials. Journal of Polymer Science, 59(16), 1748–1786.

Zhang, Y. L. (2017). Epoxy Adhesive. Beijing: Chemical Industry Press., 1–6.

Chebotareva, Ye. G., Ogrel, L. Yu. (2008). [Modern trends in the modification of epoxy polymers]. Fundamentalnye issledovaniya, (4), 102–104. (In Russian).

Sytar, V., Kuzyayev, I., Sukhyy, K., Kabat, O., (2021). [Experimental and theoretical investigation of the pore formation process in gas-filled polymeric materials]. Journal of Chemistry and Technologies, 29(2), 279–300. doi: 10.15421/jchemtech.v29i2.222917 (In Ukrainian)

Mostovoy, A. S. (2015). [Formulation modification of epoxy resins using new high-performance plasticizers]. Sovremennye naukoemkie tekhnologii, (7), 66–70. (In Russian).

Gotlib, Ye. M., Cherezova, Ye. N., Ilicheva, Ye. S., Medvedeva, K. A. (2014). [Epoxy copolymers. Curing, modification, application as glues: monograph]. Kazan: Izd-vo KNITU. (In Russian).

Nielsen, L. E., Landel, R. F. (1994). Mechanical properties of polymers and composites. 2-nd ed. New York: Marcel Dekker.

Zaytsev, Yu. S., Kochergin, Yu. S., Pakter, M. K., Kucher, R. V. (1990). [Epoxy oligomers and adhesive compositions]. Kiev: Nauk. dumka. (In Russian).

Khozin, V. G. (2004). [Hardening of epoxy polymers]. Kazan: PIK "Dom pechati". (In Russian).

Irzhak, V. I., Rozenberg, B. A., Yenikolopyan, N. S. (1979). [Network polymers: synthesis, structure, properties]. М: Nauka. (In Russian).

Hodgkin, J. H., Simon, G. P., Varley, R. J. (1998). Thermoplastic toughening of epoxy resins: A critical review. Polymers for Advanced Technologies. 9(1): 3–10.

Zhao, J. L., Zhang, G.C., Li, H.Q. (2002). Research progress in toughening epoxy resin. Plastics. 31(3), 490–495.

Liu, D., Zhao, W. J., Wu, F., Cen, Q., Zeng, Zh., Wu, X., Qunji, X. (2015). The effect of curing agent molecular structure on the friction and corrosion properties of epoxy resin coatings. Automotive and Motorcycle Tribological Materials Advanced Technology and Application Promotion Association.; 472: 85–91.

Bogdanova, L.M., Kuzub, L.I., Dzhavadyan, E.A., Torbov, V.I., Dremova, N.N., Pomogailo, A.D., (2014). Mechanical properties of epoxy composites based on silver nanoparticles formed in situ. Polym. Sci. Ser. A, 56(3), 304–310.

Irzhak, V.I., Rozenberg, B.A. (1985). [Peculiarities of the kinetics of mesh polymers formation]. Vysokomolekulyarnye soedineniya. Series А., 27(9), 1795–1808. (In Russian).

Pascault, J.-P., Willims, R. J. (2010). Epoxy polymers: new materials and innovations. Wiley-VCH, Verlag GmbH&Co. KGaA, Weinheim.

Meirbekov, M. N., Ismailov, M. B., Manko, T. A. (2020). The effect of modification of an epoxy resin by liquid oligomers on physical-mechanical properties of composites. Voprosy khimii i khimicheskoi technologii, (3), 122–127.

Wu, Ch., Xu, W. (2006). Atomistic molecular modeling of crosslinked epoxy resin. Polymer, 47, 6004–6009.

Acebo, C., Ramis, X., Serra, A. (2017). Improved epoxy thermosets by the use of poly (ethyleneimine) derivatives. Physical Sciences Reviews, 2(8), 20160128-1-20160128-34. doi:10.1515/psr-2016-0128.

Gavrilov, A. A., Komarov, P. V. and Khalatur, P. G. (2015). Thermal properties and topology of epoxy networks: a multiscale simulation methodology. Macromolecules, 48(1), 206–212.

Radue, M. S., Varshney, V., Baur, J. W., Roy, A. K., Odegard, G. M. (2018). Molecular modeling of cross-linked polymers with complex cure pathways: a case study of bismaleimide resins. Macromolecules, 51(5), 1830–1840.

Sukhyy, K. M., Belyanovskaya, E. A., Nosova, A. N., Sukhyi, M. K., Huang, Y., Kocherhin, Yu., Hryhorenko T. (2021). Properties of epoxy-thiokol materials based on the products of the preliminary reaction of thioetherification. Voprosy Khimii i Khimicheskoi Tekhnologii, 3, 128–136.

Sukhyy, K. M., Belyanovskaya, E. A., Nosova, A. N., Sukhyi, M. K., Huang, Y., Kocherhin, Yu., Hryhorenko T. (2021). Influence of concentration of thiokol, amount of the hardener and filler on properties of epoxide-polysulphide composites. Journal of Chemistry and Technologies, 29(4), 537–545. https://doi.org/10.15421/jchemtech.v29i4.236607

Sukhyy, K. M., Nosova, A. N., Belyanovskaya, E. A., Sukha I. V., Yiqi, Wu, Kocherhin, Yu., Hryhorenko, T. (2021). [Effect of diluents and plasticizers on the properties of epoxy-polysulfide composites]. Polymer Journal, 43(3), 172–179. (In Ukrainian).

Catalog Epikote https://www.hexion.com/en-GB/brand/epikote.

Downloads

Published

Issue

Section

License

Copyright (c) 2022 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).