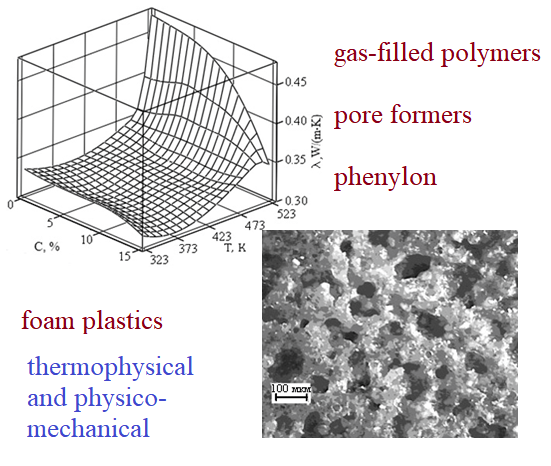

HEAT-RESISTANT GAS-FILLED COMPOSITES BASED ON PHENYLON AND INORGANIC PORE FORMERS

DOI:

https://doi.org/10.15421/jchemtech.v31i1.268810Keywords:

gas-filled polymers, pore formers, phenylon, foam plastics, thermophysical and physico-mechanical propertiesAbstract

Heat-resistant gas-filled polymer-based composites with inorganic pore formers were developed in the work. Aromatic polyamide phenylon, which is one of the heat-resistant and strongest polymers, was chosen as the polymer base. To reduce the viscosity of its melt during processing, PMS-500 oligosiloxane liquid was introduced into the products. It was established that the optimal content of this modifier is 2 % by mass. At this content of oligosiloxane liquid, the lowest values of polymer composite melt viscosity are observed during processing into products. To create a gas-filled composition, the following pore formers were studied: ammonium chloride (NH4Cl), magnesium carbonate (MgCO3), and polyvinyl alcohol (PVA). As a result of their thermogravimetric analysis, it was established that the most suitable pore former for aromatic polyamide is MgCO3, the decomposition products of which are able not only to create pores in the polymer, but also to thermostabilize it, which is proven by the increase in the Vicat softening temperature values of the obtained polymer composite materials. А study of the thermophysical characteristics of the developed foams based on phenylon, namely the apparent density, heat capacity, and thermal conductivity. It was established that their values are at the level of the best analogues. Based on the fact that in values of strength (up to 6 MPa) and maximum operating temperature (up to 557 K), the developed foams based on phenylon significantly exceed the best analogues, they can be recommended for use as foams operating at a significant level of loads and temperatures.

References

Kornienko V.P., Shirshin K.V., Gorelov Yu.P., Kuznetsova A.V., Chervyakova G.N., Khokhlova T.A. (2013). [Poluchenie vspenennykh poliimidnykh materialov na osnove akrilonitrila i (met)akrilovoy kisloty]. Plasticheskie massy, 6, 14 18. (in Russian).

Sytar, V.I., Kuzyayev, I.M., Sukhyy, K.M., Kabat, O.S., Belyanovskaya, E.A. (2019). A study of influence of nature and concentration of porogenes on phenylone structure and properties. Voprosy Khimii i Khimicheskoi Tekhnologii, 6, 116–122. http://dx.doi.org/10.32434/0321-4095-2019-127-6-213-220

Gur’ev, V., Nikitin, V., Kofanov, V. (2019). [Investigation of heat-humidity transfer in high-porous gas-filled polymers to calculate its heat conductivity]. International Journal for Computational Civil and Structural Engineering, 15(1), 67–77. doi: 10.22337/2587-9618-2019-15-1-67-77 (in Russian).

Feld, L., Hugo da Silva, V., Strand, J. (2022). Characterization of foamed plastic litter on Danish reference beaches – Pollution assessment and multivariate exploratory analysis. Marine Pollution Bulletin, 180, 1–10. https://doi.org/10.1016/j.marpolbul.2022.113774

Wu, Y., Zhang, C., Wang, C., Wan, J., Wei, N., Zhu, C., Fang, H., Zou, Z. (2022). Micro-mechanical properties of foamed polymer rehabilitation material: A molecular dynamics study. Polymer, 263, 1–10. https://doi.org/10.1016/j.polymer.2022.125480

Mikhaylin, Yu. A. (2006) [Heat-resistant polymers and polymeric materials]. St. Petersburg: Profession (in Russian).

González-Díaz, M. O., Cetina-Mancilla, E., Sulub-Sulub, R. Montes-Luna, A., Olvera, L. I., Zolotukhin, M. G., Cárdenas, J., Aguilar-Vega M. (2020). Novel fluorinated aromatic polymers with ether-bond-free aryl backbones for pure and mixed gas separation. Journal of Membrane Science, 606. https://doi.org/10.1016/j.memsci.2020.118114

Kholkhoev, B. Ch., Bardakova, K.N., Minaev, N. V. (2019). Robust thermostable polymer composition based on poly[N,N′-(1,3-phenylene)isophthalamide] and 3,3-bis(4-acrylamidophenyl)phthalide for laser 3D printing. Mendeleev Communications, 29(2), 223–225. http://dx.doi.org/10.32434/0321-4095-2019-127-6-213-220

Kabat, O., Sytar, V., Derkach, O., Sukhyy, K. (2021). Рolymeric composite materials of tribotechnical purpose with a high level of physical, mechanical and thermal properties. Chemistry & Chemical Technology, 15(4), 543–550. https://doi.org/10.23939/chcht15.04.543

Kabat, O.S., Kharchenko, B.G., Derkach, A.D., Artemchuk, V.V., Babenko, V.G. (2019). [Polymer composite materials based on fluoroplast and the method of their production]. Voprosy Khimii i Khimicheskoi Tekhnologii, 3, 116–122. (in Russian). http://dx.doi.org/10.32434/0321-4095-2019-124-3-116-122

Каbаt, О.S., Derkach, O.D., Pavlushkina, N.V., Pikula І.І. (2019). Polymeric composites of tribotechnical purpose based on fluoropolymers. Problems of Tribology, 92(2), 75–81.

Habib, S., Weinman, S. T. (2021). A review on the synthesis of fully aromatic polyamide reverse osmosis membranes. Desalination, 502, 1–9. https://doi.org/10.1016/j.desal.2021.114939

Wu, Z., He, J., Yang, H., Yang, S. (2022). Progress in Aromatic Polyimide Films for Electronic Applications: Preparation, Structure and Properties. Polymers, 14(6), 1–15. https://doi.org/10.3390/polym14061269

Sokolov, L.B., Gerasimov, V.D., Savinov, V.M., Belyakov, V.K. (1967). [Heat-resistant aromatic polyamides]. M: Chemistry. (in Russian).

Kabat, O., Makarenko, D., Derkach, O., Muranov, Y. (2021). Determining the influence of the filler on the properties of structural thermal-resistant polymeric materials based on phenylone C1. Eastern-European Journal of Enterprise Technologies, 6(113), 24–29. https://doi.org/10.15587/1729-4061.2021.243100

Kabat, O., Sytar, V., Heti, K., Artemchuk, V. (2021). А Method for obtaining a polymer composite based on aromatic polyamide and silicon dioxide. Journal of Chemical Technology and Metallurgy, 56(2), 283–288

Kobets, A.S., Derkach, O. D., Kabat, O. S., Volovyk, I. A., Kovalenko, V. L., Kotok, V. A., Verbitskiy, V. V. (2020). Investigation friction and wear of constructional plastics based on aromatic polyamide. ARPN Journal of Engineering and Applied Sciences, 15(10), 1189–1195. http://www.arpnjournals.com/jeas/volume_10_2020.htm

Kabat, O., Sytar, V., Sukhyy, K. (2018). Antifrictional polymer composites based on aromatic polyamide and carbon black. Chemistry & Chemical Technology, 12(3), 326–330. https://doi.org/10.23939/chcht12.03.326

Sitar, V.I., Kuzyaev, I.M., Danilin, D.S. (2003). [Research on melt rheology of modified systems based on fenilone]. Questions of chemistry and chemical technology, 2, 104–107. (in Ukrainian).

Sytar, V.I., Burya, A.I., Danilin, D.S., Kholodilov, O. V. (2004). [Study of the influence of organosiloxanes on the properties of aromatic polyamide-phenylone]. Materials, technologies, tools, 9(3), 59–62 (in Russian).

Sitar, V.I., Kabat, O.S., Kolyada, D.Yu., Khorenko, D.,I (2020). Ukraine Patent No. 121913. (in Ukrainian).

Kabat, O. S., Sitar, V.I., Sykhy, K.M. (2017). Determination of optimal technological parameters during the processing of pressed powders of aromatic polyamides into products. Polymer Journal, 4, 248–252.

Liu, Q., Tang, Z., Ou, B, Liu, L., Zhou, Z., Shen, S., Duan Y. (2014). Design, preparation, and application of ordered porous polymer materials. Materials Chemistry and Physics, 144(3), 213–225. https://doi.org/10.1016/j.matchemphys.2014.01.013

Gokmen, M. T., Du Prez, F. E. (2014). Porous polymer particles—A comprehensive guide to synthesis, characterization, functionalization and applications. Progress in Polymer Science, 37(3), 365–405. https://doi.org/10.1016/j.progpolymsci.2011.07.006

Lermontov, S.A., Malkova, Al.N., Sipyagina, N.A. (2019). Properties of highly porous aerogels prepared from ultra-high molecular weight polyethylene. Polymer, 182. https://doi.org/10.1016/j.polymer.2019.121824

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).