OPTIMIZATION OF THE PARAMETERS OF BIOCATALYTIC HYDROLYSIS OF VEGETABLE OIL USING THE METHODS OF NEURAL NETWORKS AND GENETIC ALGORITHMS

DOI:

https://doi.org/10.15421/jchemtech.v31i1.274704Keywords:

hydrolysis, lipase, biocatalysis, artificial neural network, genetic algorithmAbstract

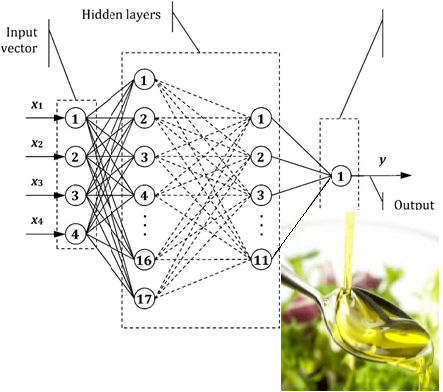

At present, ensuring the competitiveness of domestic oil and fat products on the domestic and foreign markets should be implemented at the expense of knowledge-intensive production based on the introduction of innovations that provide a qualitatively new level of technological development. In this regard, in the presented work, research was carried out on the optimization of the parameters of biocatalytic hydrolysis of sunflower oil. NovoCor AD L (Novozymes, Denmark) enzyme preparation was used as a biocatalyst. The mathematical apparatus of artificial neural networks was used for the process modelling. The three-layer direct signal transmission network developed as a result of construction, learning and verification was used to calculate the fitness function in the optimization of biocatalytic hydrolysis using genetic algorithms. The software implementation of the mathematical apparatus was performed in the MATLAB environment. The conducted research made it possible to establish the optimal values of the main parameters of the biocatalytic hydrolysis of vegetable oil: the molar ratio of water to oil is 14 : 1, the amount of enzyme is 3.75 % in relation to the mass of oil, the temperature is 60 °C, and the reaction time is 480 minutes. The set optimal parameters were tested in the conditions of experimental and industrial production. According to the test results, the degree of oil hydrolysis was 96 ± 1.8 %, which correlates well with the modelling data.

References

Ahmad, M.U. (2017). Fatty Acids: Chemistry, Synthesis, and Applications. USA: Academic Press and AOCS Press.

Nekrasov, P.O., Berezka, T.O., Nekrasov, O.P., Gudz, O.M., Rudneva, S.I., Molchenko, S.M. (2022). Study of biocatalytic synthesis of phytosterol esters as formulation components of nutritional systems for health purposes. Journal of Chemistry and Technologies, (3), 404–409. https://doi.org/10.15421/jchemtech.v30i3.265174

Shahidi, F. (2020). Bailey's industrial oil and fat products. Hoboken, USA: John Wiley & Sons Inc.

Satyarthi J.K., Srinivas D., Ratnasamy, P. (2011). Hydrolysis of vegetable oils and fats to fatty acids over solid acid catalysts, Appl. Catal., A., 391 (1–2), 427–435. https://doi.org/10.1016/j.apcata.2010.03.047

Milliren, A.L., Wissinger, J.C., Gottumukala, V., Schall C.A. (2013). Kinetics of soybean oil hydrolysis in subcritical water. Fuel, 108, 277–281. https://doi.org/10.1016/j.fuel.2012.12.068

de María, P. D., de Gonzalo, G., Alcántara, A. R. (2019). Biocatalysis as useful tool in asymmetric synthesis: An assessment of recently granted patents (2014-2019). Catalysts, 9(10), 802. https://doi.org/10.3390/catal9100802

Basso, A., Serban, S. (2019). Industrial applications of immobilized enzymes – A review. Mol. Catal., 479, 110607. https://doi.org/10.1016/j.mcat.2019.110607

Britton, J., Majumdar, S., Weiss, G. A. (2018). Continuous flow biocatalysis. Chem. Soc. Rev., 47(15), 5891–5918. https://doi.org/10.1039/c7cs00906b

Prasad, S., Roy, I. (2018). Converting enzymes into tools of industrial importance. Recent Pat. Biotechnol., 12(1), 33–56. https://doi.org/10.2174/1872208311666170612113303

Cerminati, S., Eberhardt, F., Elena, C. E., Peirú, S., Castelli, M. E., Menzella, H. G. (2017). Development of a highly efficient oil degumming process using a novel phosphatidylinositol-specific phospholipase C enzyme. Appl. Microbiol. Biotechnol., 101(11), 4471–4479. https://doi.org/10.1007/s00253-017-8201-0

Gligor, O., Mocan, A., Moldovan, C., Locatelli, M., Crișan, G., Ferreira, I. C. F. R. (2019). Enzyme-assisted extractions of polyphenols – A comprehensive review. Trends Food Sci. Technol., 88, 302–315. https://doi.org/10.1016/j.tifs.2019.03.029

Xiaoyang, S., Shaojun, T., Lifen, Z., Jianchun, X. (2019). Effect of phospholipase A1 -catalyzed degumming on oryzanol, tocopherols, and tocotrienols of dewaxed rice bran oil. J. Chem., 2019, 1608750. https://doi.org/10.1155/2019/1608750

Tufiño, C., Bernal, C., Ottone, C., Romero, O., Illanes, A., Wilson, L. (2019). Synthesis with immobilized lipases and downstream processing of ascorbyl palmitate. Molecules, 24(18), 3227. https://doi.org/10.3390/molecules24183227

Zorn, K., Oroz-Guinea, I., Brundiek, H., Bornscheuer, U.T. (2016). Engineering and application of enzymes for lipid modification, an update. Prog. Lipid Res., 63, 153–164. https://doi.org/10.1016/j.plipres.2016.06.001

Serrano-Arnaldos, M., Bastida, J., Máximo, F., Ortega-Requena, S., Montiel, C. (2018). One-step solvent-free production of a spermaceti analogue using commercial immobilized lipases. ChemistrySelect, 3(2), 748–752. https://doi.org/10.1002/slct.201702332

Nekrasov, P.O., Piven, O.M., Nekrasov, O.P., Gudz, O.M., Kryvonis, N.O. (2018). Kinetics and thermodynamics of biocatalytic glycerolysis of triacylglycerols enriched with omega-3 polyunsaturated fatty acids. Voprosy khimii i khimicheskoi technologii – Issues of Chemistry and Chemical Technology, (5), 31–36.

Nekrasov, P.O., Gudz, O.M., Nekrasov, O.P., Kishchenko, V.A., Holubets, O.V. (2019). [Fatty systems with reduced content of trans-fatty acids]. Voprosy khimii i khimicheskoi technologii – Issues of Chemistry and Chemical Technology, (3), 132–138 (in Ukrainian). https://doi.org/10.32434/0321-4095-2019-124-3-132-138

Nekrasov, P.O., Gudz, O.M., Nekrasov, O.P., Berezka, T.O. (2020) Optimizing the parameters of the production process of fat systems with a minimum content of trans-isomers. Voprosy khimii i khimicheskoi technologii – Issues of Chemistry and Chemical Technology, (3), 128–133. https://doi.org/10.32434/0321-4095-2020-130-3-128-133

Sarmah, N., Revathi, D., Sheelu, G., Yamuna Rani, K., Sridhar, S., Mehtab, V., Sumana, C. (2018). Recent advances on sources and industrial applications of lipases. Biotechnol. Prog., 34(1), 5–28. https://doi.org/10.1002/btpr.2581

Filho, D. G., Silva, A. G., Guidini, C. Z. (2019). Lipases: sources, immobilization methods, and industrial applications. Appl. Microbiol. Biotechnol., 103(18), 7399–7423. https://doi.org/10.1007/s00253-019-10027-6

Javed, S., Azeem, F., Hussain, S., Rasul, I., Siddique, M. H., Riaz, M., Afzal, M., Kouser, A., Nadeem, H. (2018). Bacterial lipases: A review on purification and characterization. Prog. Biophys. Mol. Biol., 132, 23–34. https://doi.org/10.1016/j.pbiomolbio.2017.07.014

Ávila, S. N. S., Gutarra, M. L. E., Fernandez-Lafuente, R., Cavalcanti, E. D. C., Freire, D. M. G. (2019). Multipurpose fixed-bed bioreactor to simplify lipase production by solid-state fermentation and application in biocatalysis. Biochem. Eng. J., 144, 1–7. https://doi.org/10.1016/j.bej.2018.12.024

Priyanka, P., Tan, Y., Kinsella, G. K., Henehan, G. T., Ryan, B. J. (2019). Solvent stable microbial lipases: Current understanding and biotechnological applications. Biotechnol. Lett., 41(2), 203–220. https://doi.org/10.1007/s10529-018-02633-7

Carpen, A., Bonomi, F., Iametti, S., Marengo, M. (2019). Effects of starch addition on the activity and specificity of food-grade lipases. Biotechnol. Appl. Biochem., 66(4), 607–616. https://doi.org/10.1002/bab.1761

Melani, N. B., Tambourgi, E. B., Silveira, E. (2020). Lipases: from production to applications. Sep. Purif. Rev., 49(2), 143–158. https://doi.org/10.1080/15422119.2018.1564328

Abdullah, S., Pradhan, R. C., Pradhan, D., Mishra, S. (2021). Modeling and optimization of pectinase-assisted low-temperature extraction of cashew apple juice using artificial neural network coupled with genetic algorithm. Food Chem., 339, 127862. https://doi.org/10.1016/j.foodchem.2020.127862

Sales de Menezes, L. H., Carneiro, L. L., Maria de Carvalho Tavares, I., Santos, P. H., Pereira das Chagas, T., Mendes, A. A., Paranhos da Silva, E.G., Franco, M., Rangel de Oliveira, J. (2021). Artificial neural network hybridized with a genetic algorithm for optimization of lipase production from penicillium roqueforti ATCC 10110 in solid-state fermentation. Biocatal. Agric. Biotechnol., 31, 101885. https://doi.org/10.1016/j.bcab.2020.101885

Bhagya Raj, G. V. S., Dash, K. K. (2022). Ultrasound assisted osmotic dehydration of dragon fruit slices: Modeling and optimization using integrated artificial neural networks and genetic algorithms. J. Food Process. Preserv., 46(11), e16993. https://doi.org/10.1111/jfpp.16993

Das, S., Samanta, T., Datta, A. K. (2021). Improving black tea quality through optimization of withering conditions using artificial neural network and genetic algorithm. J. Food Process. Preserv., 45(3), e15273. https://doi.org/10.1111/jfpp.15273

Lee, G. E., Kim, R. H., Lim, T., Kim, J., Kim, S., Kim, H. -G., Hwang, K. T. (2022). Optimization of accelerated solvent extraction of ellagitannins in black raspberry seeds using artificial neural network coupled with genetic algorithm. Food Chem., 396, 133712. https://doi.org/10.1016/j.foodchem.2022.133712

International Organization for Standardization. (2020). Animal and vegetable fats and oils – Determination of acid value and acidity. (ISO 660:2020). Geneva, Switzerland: International Organization for Standardization.

International Organization for Standardization. (2020). Animal and vegetable fats and oils – Determination of saponification value. (ISO 3657:2020). Geneva, Switzerland: International Organization for Standardization.

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).