INFLUENCE OF OLIGOMERIC RUBBERS ON THE BEHAVIOR OF EPOXY COMPOSITIONS UNDER DYNAMIC CONTACT LOADING AND THEIR WEAR RESISTANCE

DOI:

https://doi.org/10.15421/jchemtech.v31i4.276862Keywords:

epoxy compositions, oligomeric rubbers, phase morphology, deformation energy components, active and passive phases of deformation, dynamic modulus of elasticity, wear resistanceAbstract

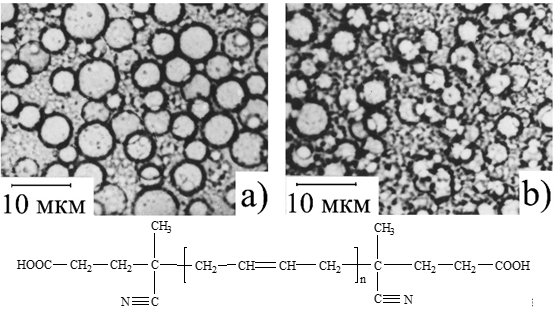

Aim. Comparative assessment of the influence of the chemical structure of oligomeric rubbers with reactive groups in the composition of protective wear-resistant epoxy compositions on the features of their phase morphology and deformation under the action of contact-dynamic loading, wear resistance. Methods. Optical microscopy to determine the phase morphology of modified epoxy compositions, size distribution of the heterophase (oligomeric rubbers) using the point method of Glagolev and linear Rosival, pulsed dynamic indentation, Maxwell and Kelvin-Voigt models to characterize viscoelastic properties. Results. The effect of oligomeric rubbers with reactive groups (carboxyl, hydroxyl, epoxy, acylhydrazone) on the behavior of epoxy compositions based on dian resin under contact-dynamic loading conditions has been determined, and extreme dependences of the active (embedding into the matrix) and passive (rebound from the surface) phases of the process on energy components of their deformation (elastic and viscous), which is associated with the formation of the phase morphology of compositions with different degrees of dispersity of the heterophase. It was found that the maximum wear and deformation of the modified epoxy compositions are related to their dynamic modulus of elasticity by straight-line relationships, the equations of which, using the experimental value of the maximum deformation, make it possible to predict the dynamic modulus of elasticity and, accordingly, the maximum wear of the compositions. The possibility of reducing (by 32 %) the maximum wear of an industrial epoxy composition highly filled with multidisperse silicon carbide with the introduction of oligomeric nitrile butadiene rubber with terminal carboxyl groups SKN-10 KTR was shown.

References

Melnyk, O. V., Smirnov, I. V., Labunets, V. F., Chorniy, O. V. (2020). [Research on the wear resistance of plasma coatings under conditions of abrasive wear]. Problems of frictions and wear, 3(88), 126–130 (in Ukrainian). https://doi.org/10.18372/0370-2197.3(88).14928

Poloz, O. Yu., Lipytskyi, S. G., Kushchenko, S. M. (2015). [Wear-resistant epoxy composites for structural purposes]. Chemical industry of Ukraine, 5, 25–27 (in Ukrainian).

Sapronov, O.O., Nigalatii, V.D., Klevtsov, K.M., Smirnov, I.V. (2013). [Influence of the content and nature of fine filler on the mechanical properties and structure of polymer protective coatings]. Scientific Bulletin of the Kherson State Maritime Academy, 2(9), 229-237 (in Ukrainian).

Tasyurek, M., Duzcukoglu, H. (2022). Improving the wear behavior of epoxy resin with boron carbide reinforcement. Iran Polymer Journal, 31, 169–184. https://doi.org/10.1007/s13726-021-00987-w

Nassar, A., Salem, M., El-Batanony, I., Nassar, E. (2021). Improving wear resistance of epoxy/SiC composite using a modified apparatus. Polymers and Polymer Composites, 29(95), 389–399. https://doi.org/10.1177/09673911211002731

Xia, H., Li, J., Wang, K., Hou, X., Yang, T., Hu, J., Shi, Zh. (2022). Superior wear resistance of epoxy composite with highly dispersed graphene spheres. Advanced Composites and Hybrid Materials, 5, 173–183. https://doi.org/10.1007/s42114-021-00259-4

Nassar, A., Younis, M., Ismail, M., Nassar, E. (2022). Improved Wear-Resistant Performance of Epoxy Resin Composites Using Ceramic Particles. Polymers, 14(2), 2–17. https://doi.org/10.3390/polym14020333

Zhicai, Zh., Nie, Zh., Fugang, Q., Biao, Zh., Bin, L., Xiaoping, O. (2020). Reinforced Superhydrophobic Anti-Corrosion Epoxy Resin Coating by Fluorine–Silicon–Carbide Composites. Coatings, 10(12), 2–16. https://doi.org/10.3390/coatings10121244

Mark, H. F. (2002). Encyclopedia of Polymer Science and Technology. John Wiley & sons.

Pascault, J. R., Williams, J. J. (2010). Epoxy Polymers: New Materials and Innovations. John Wiley & sons.

Zaitsev, Yu. S., Kochergin, Yu. S., Pacter, N. K, Coachman, R. W. (1990). [Epoxy oligomers and adhesive compositions]. Kiev, USSR: Naukova Dumka (in Russian).

Petrie, E. M. (2006). Epoxy Adhesive Formulations. McGRAW-HILL.

Poloz, O. Yu., Ebich, Y. R. (2021). [Behavior of wear-resistant epoxy compositions in conditions of contact-dynamic loading]. Problems of frictions and wear, 2(91), 46–52 (in Ukrainian). https://doi.org/10.18372/0370-2197.2(91).15528

Wei, Hongyu, Xia, Jun, Zhou, Wanlin, Zhou, Laishui, Hussain, Ghulam, Li, Qin, Ostrikov, Kostya (2020). Adhesion and cohesion of epoxy-based industrial composite coatings. Composites Part B: Engineering, 193, 108035.

https://doi.org/10.1016/j.compositesb.2020.108035

Poloz, A. Yu., Lypytskyi, S. G., Kushchenko, S. N. (2016) [The choice of parameters for the comparative evaluation of wear resistance epoxy composite materials]. Technological audit and production reserves, 5/3 (31), 26-31. (in Russian). https://doi.org/10.15587/2312-8372.2016.81253

Hammi, Maryama, Ziat, Younes, Zarhri, Zakaryaa, Laghlimi, Charaf, Moutcine, Abdelaziz (2021). Epoxy/alumina composite coating on welded steel 316L with excellent wear and anticorrosion properties. Scientifc Reports, 11, 12928.

https://doi.org/10.1038/s41598-021-91741-y

Abdulqadir, Z. H. M., Karim, F. R. (2022). Evaluating the Efficiency of Epoxy Injection Technique for Repairing Normal and High Strength Concrete Beams -A Critical Review. Construction, 2(2), 48-55. https://doi.org/10.15282/construction.v2i2.8522

Poloz, A. Yu., Ebich, Yu. R., Dolinskaya, R. M., Prokopchuk, N. R. (2021). [Influence of epoxy-containing diluents-modifiers on the structure and properties of wear-resistant epoxy compositions]. Polymer materials and technologies, 7(3), 65–73 (in Russian).

Degtyarev O. V. (Ed.). (2018). [Science for the space industry]. Informatsionnyy byuleten' Koordinatsionnogo soveta po organizatsii sovmestnykh rabot GP «KB «Yuzhnoye» i nauchnykh uchrezhdeniy NAN Ukrainy – Information bulletin of the Coordination Council on the organization of joint work of the «KB «Yuzhnoye» and scientific institutions of the National Academy of Sciences of Ukraine, (2), 75-78 (in Russian).

Meyirbekov, M. N., Ismailov, M. B. (2020). [Influence of rubber on mechanical properties of epoxy resin and carbon fiber (Review)]. Complex Use of Mineral Resources, (1), 11-21 (in Russian). https://doi.org/10.31643/2020/6445.02

Poloz, A. Yu., Ebich, Yu. R., Prokopchuk, N. R., Dolinskaya, R. M., Mozalev, V.V. (2016). [Oligomeric rubbers with reactive groups as modifiers of epoxy wear-resistant compositions]. Voprosy khimiy i khimicheskoi technologii – Issues of Chemistry and Chemical Technology, (1), 72–76 (in Russian). http://nbuv.gov.ua/UJRN/Vchem_2016_1_14

Poloz, O. Yu., Ebich, Y. R. (2021). [Influence of oligomer rubbers on the initial stages of the formation of wear-resistant epoxy compositions]. Journal of Chemistry and Technologies, 29(4), 580–588 (in Ukrainian). https://doi.org/10.15421/jchemtech.v29i4.241644

Kochergin, Yu. S., Zolotareva, V. V., Grigorenko, T. I. (2017). [Wear resistance of composite materials based on epoxy-rubber polymers]. Bull. of Belarus State Technological Univ. (4), 10–19 (in Russian). https://doi.org/10.12737/article_58ddfc7bea0549.53745809

Clarke, A., Eberhardt, C. (2002). Microscopy Techniques for Materials Science. – New York: CRC Press LLC.

Radzinskaya, I. N., Balueva, L. I., Shtarkman, B. P. (1974). [Quantitative methods of estimating parameters of the phase morphology of polymer mixtures], Kolloidnyy zhurnal – Colloid journal, 36(2), 291–297. (in Russian).

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).