THE EFFECT OF ROUGHNESS ON THE PHYSICOCHEMICAL PROPERTIES OF A36 STEEL: PHOSPHATE ADHESION STUDY

DOI:

https://doi.org/10.15421/jchemtech.v31i3.278149Keywords:

Phosphate; low-alloy A36 steel; clogging; adhesion; surface energy; wetting.Abstract

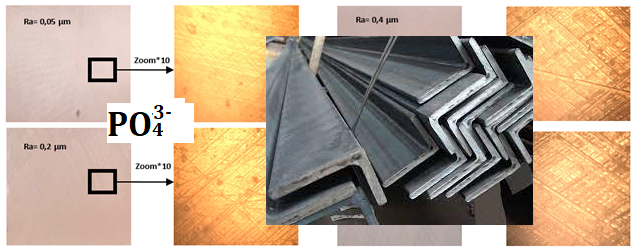

This work discusses the effect of surface roughness and surface physicochemical properties on the initial adhesion of phosphate to steel. The steel samples used in this study are made from A36 low alloy steel. The phosphate was extracted from the BenGurir-Morocco area and is used in this work in the form of pellets that were compacted using different pressures. The steel surface is treated by two methods of surface pretreatment such as honing and horizontal milling. The influence of this pretreatment procedure on the surface morphology, roughness, surface energy and hydrophobicity are examined. By measuring the contact angle on the surfaces of the phosphate pellets and the substrates of low-alloy A36 steel, we were able to identify the physicochemical parameters by calculating the surface energy. In addition, the roughness of each steel sample was investigated using the roughness meter and the metallurgical microscope. The results obtained showed that the phosphate surface is is subject to dispersing forces and has a hydrophilic character. For the surfaces of different A36 steel substrates, the effect of roughness was well examined, the minimum surface energy was obtained for both pretreatment (honing and horizontal milling) for a determined roughness. This result can be used for preparing surfaces with minimum surface energy in order to minimize fracture energy and therefore minimize the adhesion and clogging of the phosphate on steels.

References

Gooch, J. W. (2007). Encyclopedic Dictionary of Polymers. Springer-Verlag. https://doi.org/10.1007/978-1-4419-6247-8

Felder, E.;Darque-Ceretti, E. (2003). Adhésion et Adhérence. CNRS.

Medkour, M., Najih, Y., Bengourram, J., El Ghmari, A., Bachaoui, M., Latrache, H., Mabrouki, M. (2022). Mechanical and thermal characterization of natural phosphate: Clogging understanding (Part 1), Materials Today: Proceedings, 51(6), 2032–2039. https://doi.org/10.1016/j.matpr.2021.06.261

Baldan, A. (2004). Review. Adhesively-bonded joints and repairs in metallic alloys, polymers and composite materials: Adhesives, adhesion theories and surface pretreatment. Journal of Material Science, 39, 1–49. doi: 10.1023/B:JMSC.0000007726.58758.e4

Meng, Y. J., Lai, J., Mo, Sh. Y., Fang, G. P., Deng, Sh. W., Wei, X. Zh., Yang, F. Y. (2023). Investigating the deterioration mechanism of adhesion between asphalt and aggregate interface under acid rain erosion, Applied Surface Science, 639, 158171.

https://doi.org/10.1016/j.apsusc.2023.158171

Awaja, F., Gilbert, M., Kelly, G., Fox, B., Pigram, P. J. (2009). Adhesion of polymers. Progress in polymer science, 34, 948–968. https://doi.org/10.1016/j.progpolymsci.2009.04.007

Yin, W., Xie, Y., Yao, J., Song, N., Chen, K., Yin, X. (2023). Study on the effect of flocculation morphology on the floatability of talc flocs and the adhesion mechanism with air bubbles, Minerals Engineering, 203, 108317. https://doi.org/10.1016/j.mineng.2023.108317

Baldan, A. (2012). Adhesion phenomena in bonded joints. International Journal of Adhesion & Adhesives, 38, 95–116. https://doi.org/10.1016/j.ijadhadh.2012.04.007

Sun, J., Yamanaka, K., Zhou, Sh., Saito, H., Ichikawa, Y., Ogawa, K., Chiba, A. (2022). Adhesion mechanism of cold-sprayed Sn coatings on carbon fiber reinforced plastics, Applied Surface Science, 579, 151873.

https://doi.org/10.1016/j.apsusc.2021.151873

Gerberich, W. W.; Cordill, M. J. (2006). Physics of Adhesion. Report on Progress in Physics, 69, 2157–2203. https://doi.10.1088/0034-4885/69/7/R03

Homma, S., Shima, M., Takano, Y., Watanabe, T., Murakami, K., Fukuda, M., Imoto, T. (2022). Hiroshi Nishikawa, Adhesion mechanism between mold resin and sputtered copper for electromagnetic wave shield packages, Thin Solid Films, 750, 139188. https: //doi.org/10.1016/j.tsf.2022.139188

Stendardo, L., Gastaldo, G., Budinger, M., Pommier-Budinger, V., Tagliaro, I., Ibáñez-Ibáñez, P. F., Antonini, C. (2023). Reframing ice adhesion mechanisms on a solid surface, Applied Surface Science,

, 158462. https://doi.org/10.1016/j.apsusc.2023.158462

Bico, J., Tordeux, C., Quéré, D. (2001). Rough wetting. Europhysics Letters, 55, 214–220.

doi 10.1209/epl/i2001-00402-x

Quéré, D. (2008). Wetting and roughness. Annuel Review of Materials Research, 2008, 38, 71–99. https://doi.org/10.1146/annurev.matsci.38.060407.132434

Bico, J., Marzolin, C., Quere, D. (1999). Pearl Drops. Europhysics Letters, 1999, 47, 220–226. doi:10.1209/epl/i1999-00548-y

Nosonovsky, M., Bhushan, B. (2009). Superhydrophobic surfaces and emerging applications: Non-adhesion, energy, green engineering. Curr. Opin. Colloid Interface Sci., 14, 270–280. https://doi.org/10.1016/j.cocis.2009.05.004

Lafuma, A.; Quere, D. (2003). Superhydrophobic states. Nat. Mater., 2, 457–460. https://doi.org/10.1038/nmat924

Munoz-Bonilla, A., Bousquet, A., Ibarboure, E., Papon, E., Labrugère, C., Rodriguez Hernandez, J. (2010). Fabrication and Superhydrophobic Behavior of Fluorinated Microspheres. Langmuir, 2010, 26, 16775–16781. https://doi.org/10.1021/la102686y

Bhushan, B., Jung, Y. C. (2011). Natural and biomimetic artificial surfaces for super-hydrophobicity, self-cleaning, low adhesion, and drag reduction. Prog. Mater. Sci., 2011, 56, 1–108. https://doi.org/10.1016/j.pmatsci.2010.04.003

Schweigert, D., Damson, B., Lüders, H., Stephan, P., Deutschmann, O. (2020). The effect of wetting characteristics, thermophysical properties, and roughness on spray-wall heat transfer in selective catalytic reduction systems. International Journal of Heat and Mass Transfer, 152, 119554. https://doi.org/10.1016/j.ijheatmasstransfer.2020.119554

Elyaagoubi, M., Najih, Y., Khadiri, M., Mabrouki, M. Oueriagli, A. Outzourhit, A. (2017). Electrochemically deposited Bismuth-Telluride nanowires in nanoporous alumina membranes. Journal of Materials and Environmental Sciences, 8. 2070–2075.

Adar, M., Najih, Y., Charafih, Y., Rahmani, K., Khaouch, Z., Mabrouki, M. (2019). Elaboration And Characterization Of Zno Thin Films Structural And Optical Study. Journal of Physics: Conference Series. doi: 10.1088/1742-6596/1292/1/012009

Najih, Y. A., Charafih, М., Rahmani, Y., Khalid Khouch, Z., Jamaa, B., Nourreeddine, K., Mabrouki, M. (2019). Characterization of ZnO thin films elaborated by cathodic sputtering with different oxygen percentages: investigation of surface energy. Journal of Physics: Conference Series., 1292, 012015. doi: 10.1088/1742-6596/1292/1/012015

Van Oss C. J. (2006). Interfacial Forces in Aqueous Media, second ed, CRC Press, New York. https://doi.org/10.1201/9781420015768

Young, T. (1805). An essay on the cohesion of fluids. Phil. Trans. Soc. [Lon2d], 95, 65. http://dx.doi.org/10.1098/rstl.1805.0005

Van Oss, C.J., Good, R.J., Chaudhury, M.K., J. (1986). Nature of the antigen-antibody interaction: Primary and secondary bonds: Optimal conditions for association and dissociation, Coll. Inter. Sci., 376, 111, 1986. https://doi.org/10.1016/S0378-4347(00)80828-2

Wang, X., Wei, S., Wang, X., Chang, K., Yang, H., Wang, Y. (2023). Synergetic improvements in surface hydrophobicity and wear resistance of TC4 materials via the combination of rapid heating and EtOH quenching methods, Journal of Alloys and Compounds, 172582.

https://doi.org/10.1016/j.jallcom.2023.172582

Clint, J. H. (2001). Adhesion and components of solid surface energies. Current opinion in Colloid and Interface Science, 2001, 6, 28–33. doi: 10.1016/S1359-0294(00)00084-4

Adams, R.D. (2010). Adhesive Bonding. Science, Technology and Applications. UK: Wood head Publishing Limited.

Yan, C., Zhu, Y., Liu, D., Xu, H., Chen, G., Chen, M., Cai, G. (2023). Improving interfacial adhesion and mechanical properties of carbon fiber reinforced polyamide 6 composites with environment-friendly water-based sizing agent, Composites Part B: Engineering, 258, 110675.

https://doi.org/10.1016/j.compositesb.2023.110675.

Brockmann, W., Geiß, P.L., Klingen, J., Schröder, B. (2009). Adhesive Bonding. Materials, Applications and Technology. Germany: Wiley-Vch Press, Weinheim.

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).