A NEW APPROACH TO OPTIMIZATION OF MIXED REFRIGERANT COMPOSITION

DOI:

https://doi.org/10.15421/jchemtech.v31i2.278892Keywords:

Klimenko cycle, Mixed refrigerant, Compressor, Volumetric flow rate, Optimization, CryorefrigeratorAbstract

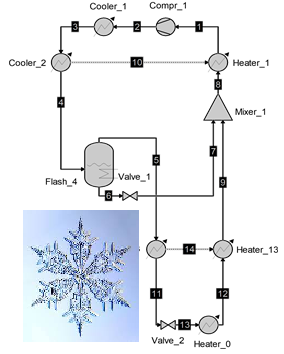

Joule-Thomson cryo-refrigerators operating on mixed working fluids have significant advantages over chillers using pure refrigerants. When optimizing the composition of zeotropic refrigerant mixtures, it is necessary to take into account the peculiarities of the operation of volumetric compressors. It is known that the flow rate of a reciprocating compressor significantly depends on the compression ratio and the compressor suction pressure. Therefore, it is impractical to optimize the composition of zeotropic refrigerant mixtures at a fixed molar flow rate, as is done in many studies. This paper describes a method for optimizing the operation of a refrigeration machine operating on a five-component zeotropic mixture of refrigerants. The maximum cooling capacity of the unit at the temperature of 120 K, which is based on a hermetic compressor TAG 2513Z, was chosen as the objective function. The following parameters were varied during the optimization: compressor discharge and suction pressures, the composition of the five-component working mixture, as well as the temperature upstream of the throttle valve, and the temperature at the inlet to the phase separator. As a result of processing the results of the numerical experiment, an analytical expression was obtained that approximates the operation of the refrigeration unit depending on the eight varied parameters. This made it possible to find the optimal operating mode of the refrigeration machine, which achieves maximum cooling capacity. At the optimum operating mode of the refrigeration unit, the suction pressure is 2.35 bars, and the discharge pressure is 16.0 bars. With the optimal composition of the working substance, the maximum cooling capacity of 147.7 W with energy consumption by the compressor of 2.36 kW is achieved.

References

Boiarski, M., Brodianski, V., Longsworth, R. (1998). Retrospective of Mixed-Refrigerant technology and modern status of cryocoolers based on one-stage, oil-lubricated compressors. Advances in Cryogenic Engineering. 43, 1701–1708.

Little, W. A. (1998). Kleemenko cycle coolers: Low cost refrigeration at cryogenic temperatures. Proceedings of IECE17, l–9.

Alexeev, A., Quack, H., Haberstroh Ch. (1998). Further development of a mixed gas Joule-Thomson refrigerator. Advances in Cryogenic Engineering, 43B, 1667–1674.

Luo, E.C., Gong ,M.Q., Zhou, Y. (2000). The research and development of cryogenic mixed-refrigerant Joule-Thomson cryocoolers in CL/CAS. Advances in Cryogenic Engineering, 45, 299–306.

Sreenivas, B., Nayak, H.G., Venkatarathnam, G. (2017). Relationship between composition of mixture charged and that in circulation in an auto refrigerant cascade and a JT refrigerator operating in liquid refrigerant supply mode. Cryogenics, 81, 42–46.

Bai, T., Yan, G., Yu, J. L. (2019). Experimental investigation on the concentration distributionbehaviors of mixture in an ejector enhanced auto-cascade refrigeration system. International Journal of Refrigeration, 99, 145–152.

Chen, Q., Hwang, Y., Yan, G. (2019). Theoretical investigation on the performance of an ejector enhanced refrigeration cycle using hydrocarbon mixture R290/R600a. Applied Thermal Engineering, 114456.

Bai. T., Li, D., Xie, H. (2020). Experimental research on a Joule-Thomson refrigerationcycle with mixture R170/R290 for -60℃ low-temperature freezer. Applied Thermal Engineering, 186(02), 116–476.

Chen, Q., Yan, G., Yu, J. (2021). Experimental research on the concentration distributioncharacteristics of dual-temperature refrigeration system using R290/R600a based onseparation condensation. International Journal of Refrigeration, 131, 244–253 https://doi.org/10.1016/j.ijrefrig.2021.06.024

Abas, N., Kalair, A.R., Khan, N., Haider, A., Saleem, Z., Saleem, M.S. (2018). Natural and synthetic refrigerants, global warming: A review. Renewable and Sustainable Energy Reviews, 90, 557–569.

Harby, K. (2017). Hydrocarbons and their mixtures as alternatives to environmental unfriendly halogenated refrigerants: An updated overview. Renewable and Sustainable Energy Reviews, 73, 1247–1264.

Fatouh, M., Abou-Ziyan, H. (2018). Energy and exergy analysis of a household refrigerator using a binary hydrocarbon mixture in tropical environment–Effects of refrigerant charge and capillary length. Applied Thermal Engineering, 145, 14–26.

Gong, M.Q. (2000). Optimum composition calculation for multicomponent cryogenic mixture used in Joule-Thomson refrigerators. Advances in Cryogenic Engineering, 45, 283–290.

Narasimhan, L. N., Venkatarathnam, G. (2011). Effect of mixture composition and hardware on the performance of a single stage JT refrigerator. Cryogenics, 51, 446–451.

Rajapaksha, L. (2007). Influence of special attributes of zeotropic refrigerant mixtures on design and operation of vapor compression refrigeration and heat pump systems. Energy Conversion and Management, 48, 539–545.

Reddy, R. K., Murthy, S. S., Venkatarathnam, G. (2010). Relationship between the cooldown characteristics of J–T refrigerators and mixturecomposition. Cryogenics, 50, 421–425.

Venkatarathnam, G., Mokashi, G., Murthy, S.S. (1996). Occurrence of pinch points incondensers and evaporators for zeotropic refrigerant mixtures. InternationalJournal of Refrigeration, 19, 361-368.

Xu, X.W., Liu, J.P., Jiang, C.S., Cao, L. (2013). The correlation between mixed refrigerant composition and ambient conditions in the PRICO LNG process. Applied Energy, 102, 1127–1136.

Technical characteristics of the TAG 2513 Z compressor manufactured by “Tecumseh”: https://www.tecumseh.com/globalassets/media/north-america/files/marketing-brochures/tecumseh-ag-compressor-information-package-14-09-01-en.pdf

Montgomery, D. C. (2019). Design and analysis of experiments (10th ed.). John Wiley& Sons.

Perez, Jose A., et. al. (2007). Effect of process variables on liquid hot water pretreatment of wheat straw for bioconversion to fuel-ethanol in a batch reactor. Journal of Chemical Technology & Biotechnology, 82(10), 929–938.

Kacker R. N., Kuhn D. R., Lei Yu, SimosD. E. (2021). Factorials Experiments, Covering Arrays, and Combinatorial. Mathematics in Computer Science, https://doi.org/10.1007/s11786-021-00502-7

Oliveira M., Lima V. M. M., Yamashita S. M. P. S., Portella A. C.F. (2018). Experimental Planning Factorial: A brief Review. International Journal of Advanced Engineering Research and Science, 5(6), 166–177. https://dx.doi.org/10.22161/ijaers.5.6.28

Ahmed, R., Mahadzir, S., Erniza Mohammad Rozali, N., Biswas, K., Matovu, F., Ahmed, K. (2021). Artificial intelligence techniques in refrigeration system modelling and optimization: A multi-disciplinary review. Sustainable Energy Technologies and Assessments, 47, 101488. doi:10.1016/j.seta.2021.101488

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).