WASTE BLAST-FURNACE SLAG AS A RESOURCE FOR THE PRODUCTION OF SLAG-ALKALINE BINDERS

DOI:

https://doi.org/10.15421/jchemtech.v31i3.279211Keywords:

waste blast-furnace slags;, slag fractions;, slag-alkaline binders;, mineralogical composition;, hardening;, strength.Abstract

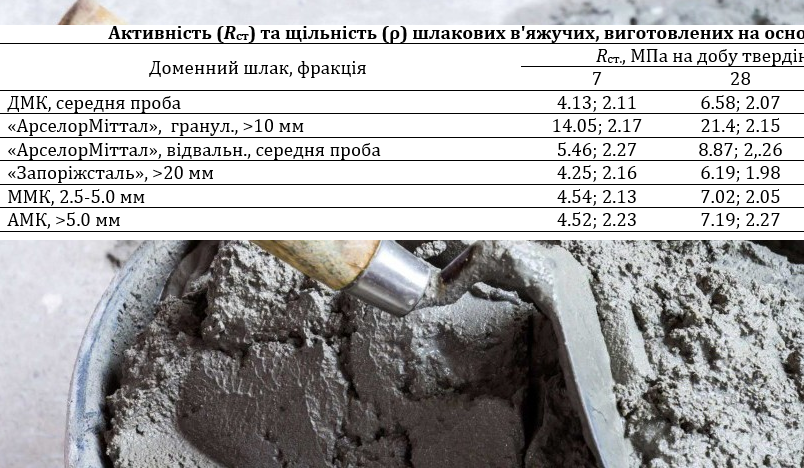

The relevance of the work is related to the solution of environmental problems while reducing the use of natural resources, CO2 emissions in the production of cement and the search for ways to create alternative binders with specific properties, one of which is slag-alkali binders (SAB). The aim of the work was to solve the problem of resource saving by identifying the useful technical properties of waste blast-furnace slags and justifying their disposal as SAB. Waste blast-furnace slags of Public Joint-Stock Company (PJSC) Dneprovskiy Metallurgical Plant, the PJSC Zaporizhstal, the Private Joint-Stock Company Mariupol Metallurgical Plant, the PJSC Alchevsk Iron and Steel Works and waste and granulated blast-furnace slag of PJSC ArcelorMittal Kryvyi Rig were studied. The slags were dispersed to a specific surface area of 2700–4950 cm2/g. For mixing, water and 20 % NaOH solution were used. The determination of the consistency of the binding paste was carried out by the method of spreading a standard cone on a vibrating table. The strength of the SAB samples was determined on a P-5 press. The mineralogical composition of the SAB was determined by X-ray phase analysis performed on a Siemens D500 powder diffractometer. Slag fractions were selected that meet the criteria for practical utilization: the ratio of oxides of the main elements, compliance with the requirements of the modular classification and the values of the quality and saturation coefficients. The interaction of slag minerals with mixing agents is confirmed by a change in the mineralogical composition of the SAB compared to the initial composition of slags. New formations are represented by Ca and Mg aluminosilicates, carbonate compounds and sodium-containing phases, which are the products of hydration hardening. The different nature of the SAB hardening products indicates the simultaneous implementation of the contact-condensation and hydration mechanisms of the process. In terms of mineralogical composition, SABs based on waste blast-furnace slags occupy an intermediate position between clinker cements and SABs based on granulated blast-furnace slags. Special properties of SAB are predicted: the duration of strength increase in time; compaction and strengthening of the structure as a result of the formation of carbonate phases; resistance to sulfate corrosion; heat resistance, which opens up the prospect of obtaining targeted concretes based on SAB using various slags.

References

Vashistha, P., Park, S., Pyo, S. (2022). A Review on Sustainable Fabrication of Futuristic Cementitious Binders Based on Application of Waste Concrete Powder, Steel Slags, and Coal Bottom. Ash. Int. J. Concr. Struct. Mater., 16(51), 51(2022). https://doi.org/10.1186/s40069-022-00541-9

Khobotova, E., Ihnatenko, M., Hraivoronska, I., Kaliuzhna, Iu. (2020). Coal Mining Waste as Raw Material for the Construction Industry. Pet. Coal, 62(3), 1112–1120.

Khobotova, E., Ihnatenko, M., Larin, V., Kalmykova, Yu., Turenko, A. (2017). Еlemental and mineral composition of ash-slag wastes of Slovianska thermal power plant. Chem. Chem. Technol., 11(3), 378–382.

Khobotova, E., Ihnatenko, M., Kaliuzhna, Iu., Hraivoronska, I. (2021). Evaluation of Radiation Security of Coal-Mining and Thermal Power Waste Products. Pet. Coal, 63(2), 517–524.

Khobotova, E., Iu. Kaliuzhna, Iu., Ihnatenko, M., Hraivoronska, I., Khodyrev, S. (2021). Radioactivity of blast furnace slags from metallurgical enterprises of Ukraine. J. of Radioanalyt. and Nuclear Chem., 327, 279–286. https://doi.org/10.1007/s10967-020-07505-x

Kazanskaya, L., Privalov, N., Privalova, S. (2019). Fine ground granulated blast furnace slag for saving quantity of binder. E3S Web of Conferences, 110, 01055, 6.

Khobotova, E. B., Kaliuzhna, Iu. S., Datsenko, V. V., Larin, V. I. (2021). Toxic and hydraulic activity of blast furnace slag as the main criteria for choosing the technology of their utilization. J. of Chem. and Techn., 29(2), 312–320. https://doi.org/10.15421/jchemtech.v29i2.228352

Jonczy, I., Grzesik, B., Wieczorek, A. N., Gerle, A., Nuckowski, P., Staszuk, M. (2022). Characteristics of the phase and chemical composition of blast furnace slag in terms of the possibility of its economic use. Gospodarka Surowcami Mineralnymi − Mineral Resources Management, 38(4), 153−172. https://doi.org/10.24425/gsm.2022.143625

Shi, C., Roy, D., Krivenko, P.V. (2019). Alkali-Activated Cements and Concretes. New York: Taylor & Francis.

Talling, B., Krivenko, P. (1996). 5 - Blast furnace slag-the ultimate binder. Waste Materials Used in Concrete Manufacturing, 235−289. https://doi.org/10.1016/B978-081551393-3.50008-9

Tänzer, R., Buchwald, A., Stephan, D. (2015). Effect of slag chemistry on the hydration of alkali-activated blast-furnace slag. Materials and Structures, 48, 629–641.

Humad, A. M., Habermehl-Cwirzen, K., Cwirzen, A. (2019). Effects of Fineness and Chemical Composition of Blast Furnace Slag on Properties of Alkali-Activated Binder. Materials, 12(20), 3447. https://doi.org/10.3390/ma12203447

Caron, R., Patel, R. A., Miron, G. D., Le Galliard, C., Lothenbach, B., Dehn, F. (2023). Microstructure development of slag activated with sodium silicate solution: Experimental characterization and thermodynamic modeling. J. of Build. Engineering, 71(15), 106398. https://doi.org/10.1016/j.jobe.2023.106398

Khobotova, E. B., Larin, V. I., Kaliuzhna, Yu. S., Storchak, O. G. (2019). Slag-alkaline binders based on dump waste blast furnace slag. Voprosy khimii i khimicheskoi tekhnologii, 5, 160−167. https://doi.org/ 10.32434/0321-4095-2019-126-5-160-167

Puertas, F., Torres-Carrasco, M. (2014). Use of glass waste as an activator in the preparation of alkali-activated slag. Mechanical strength and paste characterisation. Cement and Concrete Research, 57(3), 95−104. https://doi.org/10.1016/j.cemconres.2013.12.005

Puertas, F., Fernández-Jiménez, A., Blanco-Varela, M. T. (2004). Pore solution in alkali-activated slag cement pastes. Relation to the composition and structure of calcium silicate hydrate. Cement and Concrete Research, 34(1), 139−148. https://doi.org/10.1016/S0008-8846(03)00254-0

Yan, Yi., Yang, S.-Yu, Miron, G. D., Collings, I. E., L'Hôpital, E., Skibsted, J., Winnefeld, F., Scrivener, K., Lothenbach, B. (2022). Effect of alkali hydroxide on calcium silicate hydrate (C-S-H). Cement and Concrete Research, 151(1), 106636. https://doi.org/10.1016/j.cemconres.2021.106636

Wang, S.-D., Scrivener, K. L. (1995). Hydration products of alkali activated slag cement. Cement and Concrete Research, 25(3), 561−571. https://doi.org/10.1016/0008-8846(95)00045-E

Lopez Gonzalez, P. L., Novais, R. M., Labrincha, J., Blanpain, B., Pontikes, Yi. (2023). The impact of granulation on the mineralogy of a modified-BOF slag and the effect on kinetics and compressive strength after alkali activation. Cement and Concrete Composites, 140, 105038. https://doi.org/10.1016/j.cemconcomp.2023.105038

Hallet, V., Pedersen, M. Th., Lothenbach, B., Winnefeld, F., Eykens, L., De Belie, N., Pontikes, Yi. (2023). The hydration of ternary blended cements with Fe-rich slag from non-ferrous metallurgy and limestone. Cement and Concrete Research, 169, 107155. https://doi.org/10.1016/j.cemconres.2023.107155

Zeraoui, A., Maherzi, W., Benzerzour, M., Abriak, N. E., Aouad, G. (2023). Development of Flash-Calcined Sediment and Blast Furnace Slag Ternary Binders. Buildings, 13(2), 333. https://doi.org/10.3390/buildings13020333

Zeraoui, A. (2022). Formulation of ternary binders based on flash-calcined sediments and ground granulated blast furnace slag. Acad. J. of Civil Engineering, 40(1), 54−57. https://doi.org/10.26168/ajce.40.1.14

Stevulova, N., Junak, J., Strigac, J., Junakova, N. (2022). Recycling cement bypass dust and granulated blast furnace slag into hydraulic road binder. IOP Conf. Ser.: Mater. Sci. Eng., 1252, 012010. https://doi.org/ 10.1088/1757-899X/1252/1/012010

Siegrist, Th. (2022). X-Ray Structure Analysis, Berlin, Boston: De Gruyter. https://doi.org/10.1515/9783110610833

Rodriguez-Carvajal, J., Roisnel, T. (1998). FullProf.98 and WinPLOTR: New Windows 95/NT Applications for Diffraction. Commission for Powder Diffraction, International Union of Crystallography, Newsletter.

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).