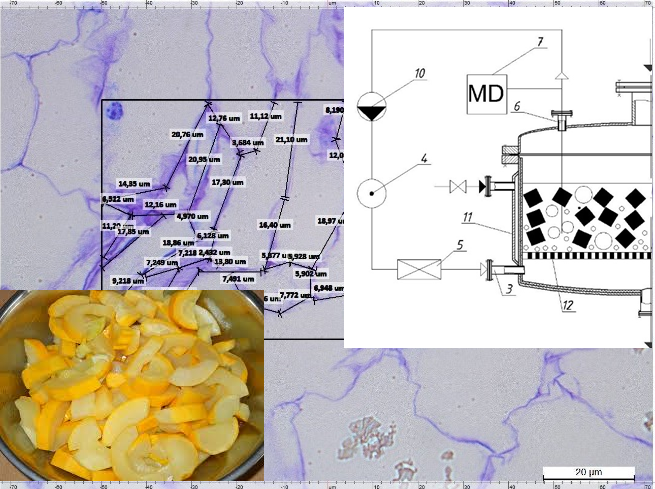

STUDY ON THE DIFFUSION PROCESS OF ZUCCHINI FRUITS SATURATION WITH SUCROSE FROM AN AQUEOUS SOLUTION

DOI:

https://doi.org/10.15421/jchemtech.v31i3.280561Keywords:

effective diffusion coefficient, mass transfer surface, external diffusion, internal diffusion region.Abstract

An important factor for the introduction of new technologies in food production is the determination of effective diffusion coefficients, forecasting the processes of saturation of vegetables and fruits with dissolved substances, obtaining mathematical models, and describing the processes of mass transfer in plant tissues. Such models need to be developed for easy use and application in a wide area of food production. Raw and blanched sections of marrow fruit were studied under a microscope, the surface of the intercellular space of slices was found and analyzed, the porosity of the mass transfer surface of raw and blanched marrow fruit was determined. A laboratory setup has been developed for studying the processes of saturation of marrow fruit with sucrose from an aqueous solution under conditions of bubbling the solution with air. Kinetic characteristics were experimentally obtained, two regions of sucrose saturation of marrow fruits were found: external diffusion and internal diffusion region. The saturation time of fruits in the external diffusion region is found. On the basis of Fick's first law, the effective diffusion coefficients of the saturation process are determined for the external diffusion and for the internal diffusion region. It has been proved that the effective diffusion coefficients for the external diffusion region increase with an increase in the rate of air supply to bubbling, and the effective diffusion coefficients for the internal diffusion region do not depend on the rate of air supply to the bubbling. On the basis of Fick's second law, equations were derived for the theoretical calculation of the dependence of the change in the concentration of sucrose in squash fruits over time. For the external diffusion region, such equations are linear. For the internal diffusion region, it is exponential. The obtained theoretical dependences can be used for designing, intensifying and optimizing the operation of a plant for saturation of particles of fruits of vegetable raw materials with dissolved substances. Experimental and theoretical findings can be used on an industrial scale.

References

Pandiselvam R, Tak Y., Olum E., Sujayasree O. J., Tekgül Y., Çalışkan Koç G., Kaur M., Nayi P., Kothakota A., Kumar M. (2022). Advanced osmotic dehydration techniques combined with emerging drying methods for sustainable food production: Impact on bioactive components, texture, color, and sensory properties of food. Journal of texture studies, 53(6), 737–762. https://doi.org/10.1111/jtxs.12643

Nowacka M., Dadan M., Tylewicz U. (2021). Current Applications of Ultrasound in Fruit and Vegetables Osmotic Dehydration Processes. Applied Sciences, 11(3), 1269. https://doi.org/10.3390/app11031269

Schudel S., Prawiranto K., Defraeye T. (2021). Comparison of freezing and convective dehydrofreezing of vegetables for reducing cell damage. Journal of Food Engineering, 293, 110376 https://doi.org/10.1016/j.jfoodeng.2020.110376

Simpson R., Ramírez C., Birchmeier V., Almonacid A., Moreno J., Nuñez H., Jaques A. (2015). Diffusion mechanisms during the osmotic dehydration of Granny Smith apples subjected to a moderate electric field. Journal of Food Engineering, 166, 204–211 https://doi.org/10.1016/j.jfoodeng.2015.05.027

González-Pérez J. E., Ramírez-Corona N., López-Malo Aurelio. (2021). Mass Transfer During Osmotic Dehydration of Fruits and Vegetables: Process Factors and Non-Thermal Methods. Food Engineering, 13, 344–374. https://doi.org/10.1007/s12393-020-09276-3

Janowicz M., Ciurzyńska A., Lenart A. (2021). Effect of Osmotic Pretreatment Combined with Vacuum Impregnation or High Pressure on the Water Diffusion Coefficients of Convection Drying: Case Study on Apples. Foods, 10(11), 2605. https://doi.org/10.3390/foods10112605

Torreggiani D. (1993). Osmotic dehydration in fruit and vegetable processing. Food Research International, 26(1), 59–68. https://doi.org/10.1016/0963-9969(93)90106-S

Ferrari C. C., Arballo J. R., Mascheroni R. H., Hubinger M. D. (2011). Modelling of mass transfer and texture evaluation during osmotic dehydration of melon under vacuum. Food Science and Technology, 46(2), 436–443 https://doi.org/10.1111/j.1365-2621.2010.02510.x

Ohnishi S., Miyawaki O. (2005). Osmotic Dehydrofreezing for Protection of Rheological Properties of Agricultural Products from Freezing-Injury. Food Science and Technology Research, 11(1), 52–58. https://doi.org/10.3136/fstr.11.52

Ramya V., Jain N. K.. (2017). A Review on Osmotic Dehydration of Fruits and Vegetables: An Integrated Approach. Journal of Food Process Engineering, 40(3), e12440. https://doi.org/10.1111/jfpe.12440

Maldonado M., González Pacheco J. (2022). Mathematical modelling of mass transfer phenomena for sucrose and lactitol molecules during osmotic dehydration of cherries. Helion, 8(1), e08788. https://doi.org/10.1016/j.heliyon.2022.e08788

Rubio-Arraez S., Capella J. V., Ortolá M. D., Castelló M. L. (2015). Modelling osmotic dehydration of lemon slices using new sweeteners. Food Science & Technology, 50(9), 2046-2051. https://doi.org/10.1111/ijfs.12859

Abraão A. S., Lemos A. M., Vilela A., Sousa J. M., Nunes F. M. (2013). Influence of osmotic dehydration process parameters on the quality of candied pumpkins. Food and Bioproducts Processing, 91(4), 481-494. https://doi.org/10.1016/j.fbp.2013.04.006

Atamanyuk, V., Huzova, I., Gnativ, Z. (2017). Study of diffusion processes in pumpkin particles during candied fruits production. Food Science and Technology, 11(4), 21–28. https://doi.org/10.15673/fst.v11i4.727

Rezagah M. E., Kashaninejad M., Mirzaei H., Khomeiri M. (2010). Osmotic dehydration of button mushroom: Fickian diffusion in slab configuration. Latin American applied research, 40(1), 23–26. http://www.scielo.org.ar/pdf/laar/v40n1/v40n1a04.pdf

Alakali J.S., Ariahu C.C., Nkpa N.N. (2006). Kinetics of osmotic dehydration of mango. Journal of food processing and preservation, 30(5), 597-607. https://doi.org/10.1111/j.1745-4549.2006.00080.x

Laura A., Rodolfo R., Mascheroni H. (2005). Rate of water loss and sugar uptake during the osmotic dehydration of pineapple. Food Science and Technology, 48 (5), 761–770 https://doi.org/10.1590/S1516-89132005000600012

Zuritz C. A., Maldonado M. B. (2005). A simple method to determine diffusion of sodium in the epidermis of green olives. Journal of Process Engineering, 27(5), 328–344 https://doi.org/10.1111/j.1745-4530.2004.00466.x

Calín-Sánchez Á., Lipan L., Cano-Lamadrid M, Kharaghani A., Masztalerz K., Carbonell-Barrachina Á. A., Figiel A. (2020). Comparison of Traditional and Novel Drying Techniques and Its Effect on Quality of Fruits, Vegetables and Aromatic Herbs. Foods, 9(9), 1261 https://doi.org/10.3390/foods9091261

Mandala G., Anagnostaras E.F., Oikonomou C.K. (2005). Influence of osmotic dehydration conditions on apple air-drying kinetics and their quality characteristics. Journal of Food Engineering, 69(3), 307-316 https://doi.org/10.1016/j.jfoodeng.2004.08.021

Kindzera, D., Hosovskyi, R., Atamanyuk, V., Symak, D. (2021). Heat transfer process during filtration drying of grinded sunflower biomass. Chemistry & Chemical Technology, 15(1), 118–124. https://doi.org/10.23939/chcht15.01.118

Huzova, I.O., Atamanyuk, V.M. (2021). Mathematical interpretation of dynamics of temperature change during drying of hot monodisperse layer of organic raw materials. Journal of Chemistry and Technologies, 28(3), 278–288. https://doi.org/10.15421/082030

Huzova, I.O., Atamanyuk, V.M. (2022). Dynamics of drying processes of plant raw material in the period of decreasing speed. Journal of Chemistry and Technologies, 30(3), 419–430. https://doi.org/10.15421/jchemtech.v30i3.259694

Huzova, I. (2020). Investigation of the energy-saving method during candied fruits filtration drying. Periodica Polytechnica Chemical Engineering, 64(4), 555–561. https://doi.org/10.3311/ppch.15107

Spiazzi E., Mascheroni R. (1997). Mass transfer model for osmotic dehydration of fruits and vegetables. Journal of Food Engineering, 34(4), 387–410 https://doi.org/10.1016/S0260-8774(97)00102-7

Seguí L., Fito P.J., Fito P. (2012). Understanding osmotic dehydration of tissue structured foods by means of a cellular approach. Journal of Food Engineering, 110(2), 240-247 https://doi.org/10.1016/j.jfoodeng.2011.05.012

Santos Barros A., Ferreira I. L., Seabra Moreira A. L. (2016). Mathematical method to characterize the inward solid state diffusion in cylindrical parts. Metallurgy and materials, 69(3), 341-348. https://doi.org/10.1590/0370-44672014690044

Kappelt C, Rzehak R. (2022). Investigation of Fluid-dynamics and Mass-transfer in a bubbly mixing layer by Euler-Euler simulation. Chemical Engineering Science, 264(31), 118147. https://doi.org/10.1016/j.ces.2022.118147

Shi P., Rzehak R. (2020). Solid-liquid flow in stirred tanks: Euler-Euler/RANS modeling. Chemical Engineering Science, 227(14), 115875. https://doi.org/10.1016/j.ces.2020.115875

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).