MECHANISM OF DETERMINING THE KINETICS OF MOISTURE CONTENT AND TEMPERATURE IN MEAT DURING CONDUCTIVE DRYING

DOI:

https://doi.org/10.15421/jchemtech.v32i1.285130Keywords:

conductive drying, kinetics, temperature, moisture content, meatAbstract

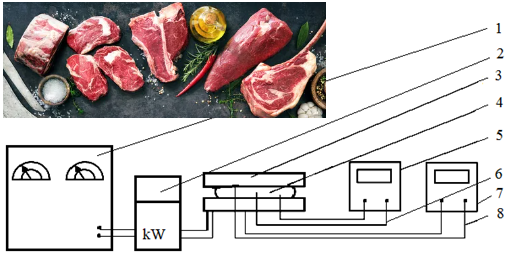

Aim. Establishing the rational thickness of meat during conductive drying based on the obtained kinetics of moisture content and temperature, specific energy consumption and organoleptic evaluation of the quality of dried products. Methods. An experimental stand has been developed for conducting research. Standard methods of analysis were used for the research – duration of the process, output of the finished product, moisture content, etc. Statistical processing of experimental research results was carried out using standard Microsoft Office and Mathcad software packages. Results. The work developed an experimental stand and proposed methods for studying the kinetics of moisture content and temperature in experimental samples of pork meat. The kinetics of moisture content and temperature in pork meat of different thicknesses were determined experimentally. It was established that the determined kinetic dependencies during conductive drying have a common feature with other drying methods, however they are compressed in time. Theoretical models of the kinetics of moisture content in meat and the kinetics of temperature in the surface layers of meat are offered in the form of modified exponents which describe the real kinetics with a reliability up to 95 %. The quality of the finished product was evaluated by the organoleptic method, according to which the dried meat with an initial thickness of 0.003 m was the best. The specific electricity consumption for the process of drying test sample of meat of different thicknesses was studied. Conclusions. A feature of conductive drying of food products is small heat loss and speed of the process. The kinetics of the moisture content of meat during conductive drying were studied. It was established that the highest quality of finished products and the lowest specific electricity consumption can be achieved with the initial thickness of the samples of 0.003 m. It is offered to remove layers of dried meat during drying using physical and electrophysical methods in order to intensify the process of conductive drying.

References

Acar, C., Dincer, I., Mujumdar, A. (2020). A comprehensive review of recent advances in renewable-based drying technologies for a sustainable future. Drying Technology, 40(6), 1029–1050. https://doi.org/10.1080/07373937.2020.1848858

Nguyen, T. K., Khalloufi, S., Mondor, M., Ratti C. (2018). Shrinkage and porosity evolution during air-drying of non-cellular food systems: Experimental data versus mathematical modelling. Food Research International, 103, 215–225.

https://doi.org/10.1016/j.foodres.2017.10.013

Perazzini, H., Leonel, A., Perazzini, M. T.B. (2021). Energy of activation, instantaneous energy consumption, and coupled heat and mass transfer modeling in drying of sorghum grains. Biosystems Engineering, 210, 181–192.

https://doi.org/10.1016/j.biosystemseng.2021.08.025

Karim, M. A., Kumar, C. (2019). Microwave-convective food drying of food materials: A critical review. Food Science and Nutrition. 59(3), 379–394. http://dx.doi.org/10.1080/10408398.2017.1373269

Khaing Hnin, K., Zhang, M., Mujumdar, A. S., Zhu, Y. (2018). Emerging food drying technologies with energy-saving characteristics: A review. Drying Technology, 37(12), 1465–1480.

https://doi.org/10.1080/07373937.2018.1510417

Berroug, F., Bellaziz, Y., Ouazzani, N., Ait Nouh, F., Hejjaj, A., Boukhattem, L., Idlimam, A., El Mahmoudi, H., Mandi, L. (2021). Experimental and numerical investigations on conductive drying of phosphate washing waste clay. Minerals, 11(5), 482.

https://doi.org/10.3390/min11050482

Jun, Q., Parag, A., Daris, M. J., Rembo, M. B., Maarten, A. I. S. (2019). A systematic analysis on tomato powder quality prepared by four conductive drying technologies. Innovative Food Science & Emerging Technologies, 54, 103–112.

https://doi.org/10.1016/j.ifset.2019.03.013

Dexiao, M., Guozhao, J., Dong, W., Aimin, L. (2021). Reinforced contact between sludge and hot wall for enhancing conductive drying by applying external load: Heat and mass transfer analysis. Process Safety and Environmental Protection, 154, 372–383.

https://doi.org/10.1016/j.psep.2021.08.021

Kroehnke, J., Szadzińska, J., Stasiak, M., Radziejewska-Kubzdela, E., Biegańska-Marecik, R., Musielak, G. (2018). Ultrasound- and microwave-assisted convective drying of carrots – Process kinetics and product’s quality analysis. Ultrasonics Sonochemistry, 48, 249–258.

https://doi.org/10.1016/j.ultsonch.2018.05.040

Bhat, Z. F, Morton, J. D., Bekhit, A. A., Kumar, S., Bhat, H.F. (2021). Thermal processing implications on the digestibility of meat, fish and seafood proteins. Comprehensive Reviews in Food Science and Food Safety, 20(5), 4511–4548.

https://doi.org/10.1111/1541-4337.12802

Demiray, E., Tulek, Y. (2014). Drying characteristics of garlic (Allium sativum L) slices in a convective hot air dryer. Heat and Mass Transfer, 50(6), 779–786.

http://dx.doi.org/10.1007/s00231-013-1286-9

Darıcı, S., Şen, S. (2015). Experimental investigation of convective drying kinetics of kiwi under different conditions. Heat and Mass Transfer, 51(8), 1167–1176.

http://dx.doi.org/10.1007/s00231-014-1487-x

Khan, A. M., Moradipour, M., Obeidullah, Md., Abdul Quader, A. K. M. (2020). Heat and mass transport analysis of the drying of freshwater fishes by a forced convective air-dryer. Journal of Food Process Engineering, 44(1), 1–21.

https://doi.org/10.1111/jfpe.13574

Ahmat, T., Bruneau, D., Djongyang, N. (2021). Drying kinetics of beef meat: Modeling by the isenthalpe mass flux method. Journal of Food Process Engineering, 44(1), 1–12. http://dx.doi.org/10.1111/jfpe.13647

Wojdyło, A., Figiel, A., Lech, K., Nowicka, P., Oszmiański, J. (2014). Effect of convective and vacuum–microwave drying on the bioactive compounds, color, and antioxidant capacity of sour cherries. Food and Bioprocess Technology, 7(3), 829–841.

http://dx.doi.org/10.1007/s11947-013-1130-8

Šumić, Z., Tepić, A., Vidović, S., Jokić, S., Malbaša, R. (2013). Optimization of frozen sour cherries vacuum drying process. Food Chemistry, 136(1), 55–63.

https://doi.org/10.1016/j.foodchem.2012.07.102

Sriariyakul, W., Swasdisevi, T.,Devahastin, S., Soponronnarit, S. (2016). Drying of aloe vera puree using hot air in combination with far-infrared radiation and high-voltage electric field: Drying kinetics, energy consumption and product quality evaluation. Food and Bioproducts Processing, 100(А), 391–400.

https://doi.org/10.1016/j.fbp.2016.08.012

Cuccurullo, G., Metallo, A., Corona, O., Cinquanta, L. (2019). Comparing different processing methods in apple slice drying. Part 1. Performance of microwave, hot air and hybrid methods at constant temperatures. Biosystems Engineering, 188, 331–344.

https://doi.org/10.1016/j.biosystemseng.2019.10.021

Wiktor, A., Nowacka, M., Dadan, M., Rybak, K., Lojkovski, W., Chudoba T., Witrova-Rajchert, D. (2016). The effect of pulsed electric field on drying kinetics, color and microstructure of carrot. Drying Technology, 34(11), 1286–1296.

https://doi.org/10.1080/07373937.2015.1105813

Dehghannya, J., Kadkhodaei, S., Heshmati, М. K., Ghanbarzadeh, B. (2019). Ultrasound-assisted intensification of a hybrid intermittent microwave – hot air drying process of potato: Quality aspects and energy consumption. Ultrasonics, 96, 104–122.

https://doi.org/10.1016/j.ultras.2019.02.005

Celen, S., Kahveci, K. (2013). Microwave drying behavior of apple slices. Process mechanical engineering, 227(4), 264–272.

https://doi.org/10.1177/0954408912464729

Krasnikov, V. V. (1973). [Conductive drying]. Moskow, USSR: Energiya (in Russian).

Skrypnyk, V., Ponomarenko, B. (2022). The possibility of applying of existing methods for the fried meat drying process. Bulletin of Poltava State Agrarian Academy, 2, 287–295 (in Ukrainian).

https://doi.org/10.31210/visnyk2022.02.34

Moses, J. A., Norton, T., Alagusundaram, K., Tiwari, B. K. (2014). Novel drying techniques for the food industry. Food Engineering Reviews, 6(3), 43–55.

http://dx.doi.org/10.1007/s12393-014-9078-7

Skrypnyk, V., Bychkov, Y., Molchanova, N., Farisieiev, A. (2018). Improving heat transfer coefficient during double-sided meat frying. Eastern-European Journal of Enterprise Technologies, 4, 11(88), 23–28.

https://doi.org/10.15587/1729-4061.2017.108855

Skrypnyk, V. O., Farisieiev, A. G. (2019). Analytical model of heat treatment of meat products with high content of connective tissue in vacuum termopackets. Journal of Chemistry and Technologies, 27(2), 201-211 (in Ukrainian).

https://doi.org/10.15421/081920

International Organization for Standardization. (1997). Meat and meat products — Determination of moisture content (Reference method). https://www.iso.org/standard/6037.html

Skrypnyk, V. O., Farisieiev, A. G. (2012). Results of studies on the quality and safety of meat products after double-sided frying in electroosmosis conditions. Scientific works of the Odessa National Academy of Food Technologies, 42(2), 406–412 (in Ukrainian).

Aykan, N. (2015). Red meat and colorectal cancer. Oncology reviews, 9, 288, 38-44.

https://doi.org/10.4081/oncol.2015.288

Mologoni, L., Daguer, H., Motta, G. E., Merlo, T. C., Dea Linder, J. D. (2019). Interactions of preservatives in meat processing: formation of carcinogenic compounds, analytical methods and inhibitory agents. Food research international, 125, 108608.

https://doi.org/10.1016/j.foodres.2019.108608

Domingo, J. L., Nadal, M. (2017). Carcinogenicity of consumption of red meat and processed meat: A review of scientific news since the IARC decision. Food and chemical toxicology, 105, 256–261.

https://doi.org/10.1016/j.fct.2017.04.028

Aksoy, A., Karasu, S., Akcicek, A., Kayacan, S. (2019). Effects of different drying methods on drying kinetics, microstructure, color, and the rehydration ratio of minced meat. Foods, 8(6), 216.

https://doi.org/10.3390/foods8060216

Ramazanov, S., Skrypnyk, V., Molchanova, N. (2015). Modeling of heat conductivity dynamics in the process of two-sided frying meat based nonlinear optimization. Technological Audit and Production Reserves, 3(3(23), 41–47 (in Ukrainian).

https://doi.org/10.15587/2312-8372.2015.44167

Marcotte, M., Taherian, A. R., Karimi, Y. (2008). Thermophysical properties of processed meat and poultry products. Journal of food engineering, 88(3), 315–322.

https://doi.org/10.1016/j.jfoodeng.2008.02.016

Roy, I., Gupta, M. N. (2004). Freeze-drying of proteins: Some emerging concerns. Biotechnol Appl Biochem., 39(2), 165–177.

https://doi.org/10.1042/BA20030133

Salehi, F. (2019). Recent applications and potential of infrared dryer systems for drying various agricultural products: a review. International Journal of Fruit Science, 20(3), 586–602.

https://doi.org/10.1080/15538362.2019.1616243

Skrypnyk, V. (2015). The theoretical substantiation of intensification process possibilities of conductive frying meat natural products. Ukrainian Journal of Food Science, 3(2), 361–367.

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).