DEVELOPMENT OF A SCHEME FOR THE UTILISATION OF SPENT LITHIUM-ION BATTERIES BY BIOLEACHING

DOI:

https://doi.org/10.15421/jchemtech.v31i3.285427Keywords:

chemical power sources; battery; lithium; utilization; bioleaching; microorganismsAbstract

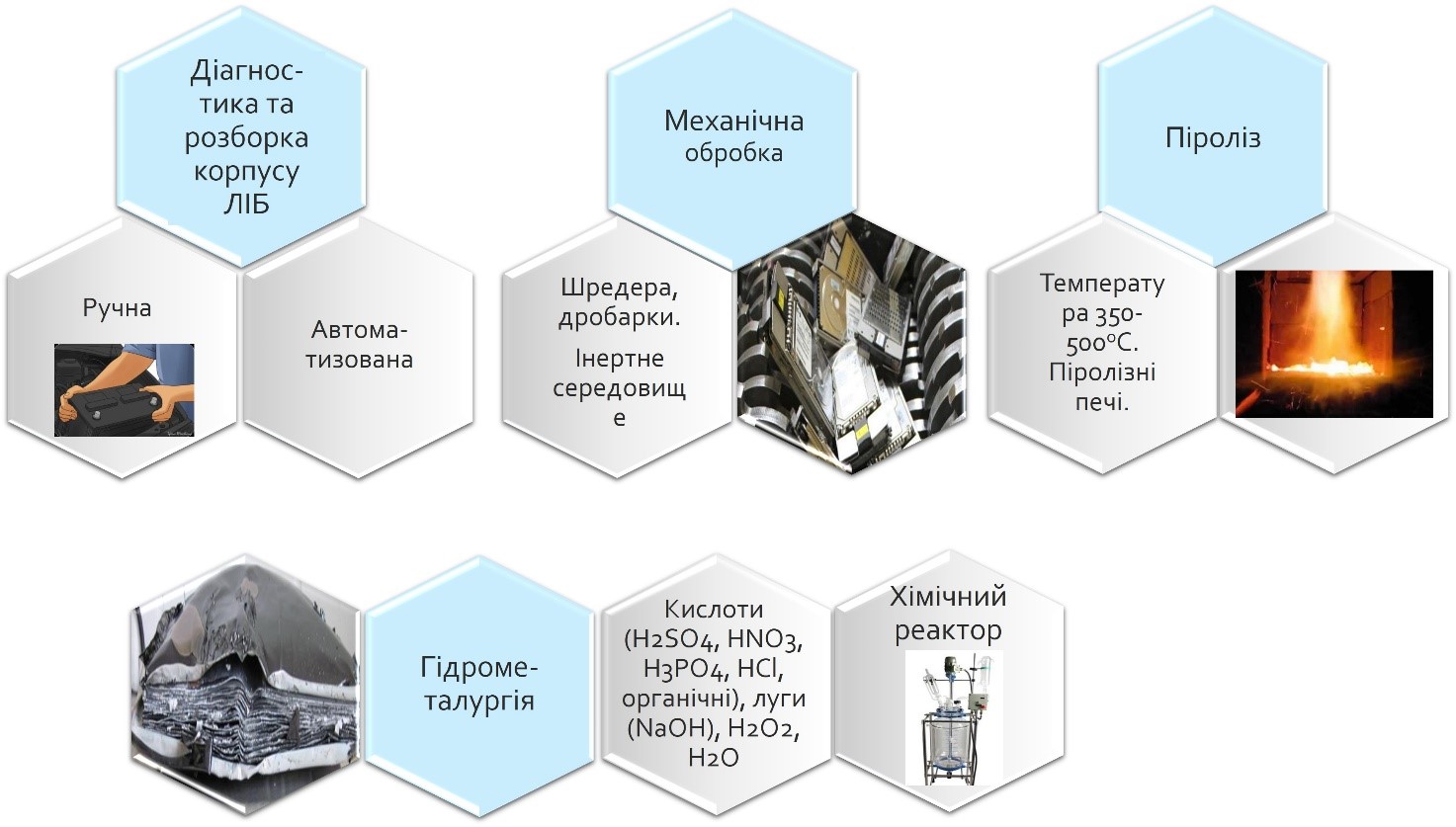

Chemical energy sources are becoming increasingly common in everyday life. At the same time, the vast majority of batteries produced are lithium-ion. Therefore, the issues related to the processing of spent batteries, in particular lithium-ion batteries, are relevant from the resource, environmental, socio-economic points of view. The study analysed current approaches to the recycling of spent lithium-ion batteries and provides a conceptual scheme of recycling. The analysis of modern developments and schemes allowed the authors to propose an environmentally friendly scheme for the utilisation of spent lithium-ion batteries by bioleaching. The scheme includes the preparation of the black mass for processing through mechanical activation in a vertical vibrating mill, followed by the decomposition of chemical compounds of the target components and their conversion into a soluble form. The conditions of the biotechnological cycle involving the metabolic potential of acidophilic mesophilic microorganisms are as follows: the amount of waste mass/bacterial suspension is in the range of 1 : 44–1 : 56; the temperature of the process is 29–30 °C; the pH value is in the range of 2.2–4.0. In contrast to traditional schemes, the proposed technology does not involve a pyrometallurgical approach and allows for effective preparation of black mass for the extraction of metals and graphite through the action of microorganisms.

References

Diouf, B., Pode, R. (2015). Potential of lithium-ion batteries in renewable energy. Renewable Energy, 76, 375–380. https://doi.org/10.1016/j.renene.2014.11.058.

Matuszak, J. The Importance of Batteries in Renewable Energy Transition. https://knowhow.distrelec.com/energy-and-power/the-importance-of-batteries-in-renewable-energy-transition/

Chen, T., Jin, Y., Lv, H., Yang, A., Liu, M., Chen, B., Xie, Y., Chen, Q. (2020). Applications of Lithium-Ion Batteries in Grid-Scale Energy Storage Systems. Trans. Tianjin Univ., 26, 208–217. https://doi.org/10.1007/s12209-020-00236-w

Costa, C.M., Barbosa, J.C., Gonçalves, R., Castro, H., Del Campo, F.J., Lanceros-Méndez, S. (2021). Recycling and environmental issues of lithium-ion batteries: Advances, challenges and opportunities. Energy Storage Materials, 37, 433–465. https://doi.org/10.1016/j.ensm.2021.02.032

Sommerville, R., Zhu P., Ali Rajaeifar, M., Heidrich, O., Goodship, V., Kendrick, E. (2021). A qualitative assessment of lithium ion battery recycling processes. Resources, Conservation and Recycling, 165, 105219. https://doi.org/10.1016/j.resconrec.2020.105219

Islam, M.T., Iyer-Raniga, U. (2022). Lithium-Ion Battery Recycling in the Circular Economy: A Review. Recycling 7, 33. https://doi.org/10.3390/recycling7030033

Golmohammadzadeh, R., Faraji, F., Jong, B., Pozo-Gonzalo, C., Banerjee, P.C. (2022). Current challenges and future opportunities toward recycling of spent lithium-ion batteries. Renewable and Sustainable Energy Reviews, 159, 112202. https://doi.org/10.1016/j.rser.2022.112202.

Jihad, A., Pratama, A. A. N., Nisa, S. A., Nisa, S. S., Yudha, C. S., Purwanto, A. (2021). Resynthesis of NMC Type Cathode from Spent Lithium-Ion Batteries: A Review. Materials Science Forum, 1044, 3–14. https://doi.org/10.4028/www.scientific.net/msf.1044.3

News. Finances. Transport. «There are already over 43,000 electric cars and hybrids in Ukraine: the regions are the leaders» https://www.unian.ua/economics/transport/elektrokari-ukrajinci-peresidayut-na-elektromobili-novini-ukrajina-11081672.html

Sobianowska-Turek, A., Urbańska, W., Janicka, A., Zawiślak, M., Matla, J. (2021). The Necessity of Recycling of Waste Li-Ion Batteries Used in Electric Vehicles as Objects Posing a Threat to Human Health and the Environment. Recycling, 6, 35. https://doi.org/10.3390/recycling6020035

Pagliaro, M., Meneguzzo, F. (2019). Lithium battery reusing and recycling: A circular economy insight. Heliyon, 5(6), e01866.https://doi.org/10.1016/j.heliyon.2019.e01866

Huang, B., Pan, Z., Su, X., An, L. (2018). Recycling of lithium-ion batteries: Recent advances and perspectives. J. Power Sources, 399, 274–286. https://doi.org/10.1016/j.jpowsour.2018.07.116

Ordoñez, J., Gago, E. J., Girard, A. (2016). Processes and technologies for the recycling and recovery of spent lithium-ion batteries. Renew. Sustain. Energy Rev., 60, 195–205. https://doi.org/10.1016/j.rser.2015.12.363

Swain, B. (2017). Recovery and recycling of lithium: A review. Separation and Purification Technology, 172, 388–403. https://doi.org/10.1016/j.seppur.2016.08.031

Chang-Heum, Jo, Seung-Taek, Myung. (2019). Efficient recycling of valuable resources from discarded lithium-ion batteries. J. Power Sources, 426, 259–265. https://doi.org/10.1016/j.jpowsour.2019.04.048

Xiao, J., Li, J., Xu, Z. (2017). Recycling metals from lithium ion battery by mechanical separation and vacuum metallurgy. J. Hazard Mater., 338, 124-131. https://doi.org/10.1016/j.jhazmat.2017.05.024

Sattar, R., Ilyas S., Bhatti, H.N., Ghaffar, A. (2019). Resource recovery of critically-rare metals by hydrometallurgical recycling of spent lithium ion batteries. Separation and Purification Technology, 209, 725–733. https://doi.org/10.1016/j.seppur.2018.09.019

Fedorov, S., Kieush, L., Koveria, A., Boichenko, S., Sybir, A. Hubynskyi M., Foris S. (2020). Thermal Treatment of Charcoal for Synthesis of High-Purity Carbon Materials. Petroleum and Coal, 62(3), 823–829.

Sehrawat, P., Julien, C., Islam, S.S. (2016). Carbon nanotubes in Li-ion batteries: A review. Mater. Sci. Eng. B, 213, 12–40. https://doi.org/10.1016/j.mseb.2016.06.013

Ates, M., Chebil, A. (2022). Supercapacitor and battery performances of multi-component nanocomposites: Real circuit and equivalent circuit model analysis. Journal of Energy Storage, 53, 105093. https://doi.org/10.1016/j.est.2022.105093

Bazaluk, O., Hrubiak, A., Moklyak, V., Moklyak, M., Kieush L., Rachiy, B., Gasyuk, I., Yavorskyi, Y., Koveria, A., Lozynskyi, V., Fedorov, S. (2021). Structurally Dependent Electrochemical Properties of Ultrafine Superparamagnetic ‘Core/Shell’ γ‐Fe2O3/Defective α‐Fe2O3 Composites in Hybrid Supercapacitors. Materials. 14, 6977. https://doi.org/10.3390/ma14226977

Owusu, K. A., Qu, L., Li, J., Wang, Z., Zhao, K., Yang, C., Hercule, K. M., Lin, C., Shi, C., Wei, Q., Zhou, L., Mai, L. (2017). Low-crystalline iron oxide hydroxide nanoparticle anode for high-performance supercapacitors. Nat. Commun., 8, 14264. https://doi.org/10.1038/ncomms14264

Kieush, L., Koveria, A. (2020). [Analysis and assessment of nanometers on the environment]. Nanosistemi, Nanomateriali, Nanotehnologii, 18(1), 141–156.

Roy, J. J., Cao, B., Madhavi, S. (2021). A review on the recycling of spent lithium-ion batteries (LIBs) by the bioleaching approach. Chemosphere, 282, 130944. https://doi.org/10.1016/j.chemosphere.2021.130944.

Zhang, X., Shi, H., Tan, N., Zhu, M., Tan, W., Daramola, D., Gu, T. (2023). Advances in bioleaching of waste lithium batteries under metal ion stress. Bioresour. Bioprocess. 10(19), 1834. https://doi.org/10.1186/s40643-023-00636-5

Kumar B. B., Rajasekhar B. (2023). Recovery of valuable metals from spent lithium-ion batteries using microbial agents for bioleaching: a review. Front. Microbiol., 14, 2023. https://doi.org/10.3389/fmicb.2023.1197081

Haghshenas, D.F., Bonakdarpour, B., Alamdari, E.K., Nasernejad, B. (2012). Optimization of physicochemical parameters for bioleaching of sphalerite by Acidithiobacillus ferrooxidans using shaking bioreactors. Hydrometallurgy. 111/112, 22–28. https://doi.org/10.1016/j.hydromet.2011.09.010

Svietkina, O., Bas, K., Alfaqs, F., Ziborov, K., Fedoskin, V. (2019). Mechanochemical Activation of Materials to Produce Conductive and Superconductive Substances for Batteries. In Solid State Phenomena, 291, 121–130. https://doi.org/10.4028/www.scientific.net/ssp.291.121

Svietkina, O., Bas, K., Haddad, J., Ziborov, K., Olishevska, V. (2020). Mechanochemical Activation of Polymetallic Ore and Further Selective Floatation. Key Engineering Materials, 844, 65–76. https://doi.org/10.4028/www.scientific.net/kem.844.65

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).