CONVERSION OF LIQUID TO STEAM. HOW AND WHY?

DOI:

https://doi.org/10.15421/jchemtech.v31i3.285771Keywords:

Isobaric and isochoric thermodynamic processes of steam overheating, Steam turbine plant, Power, Thermal efficiencyAbstract

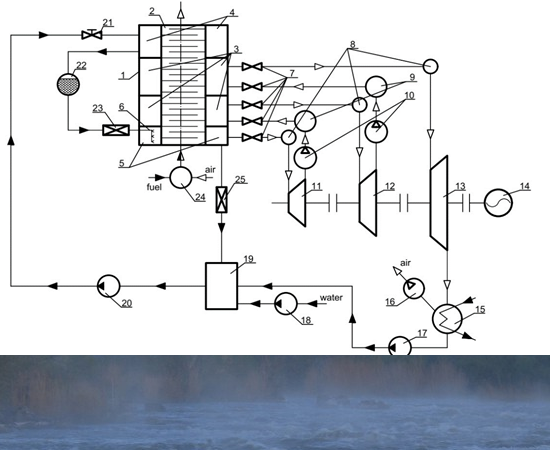

To convert liquid into vapor, static and hydrodynamic methods are used. When using the hydrodynamic method, the transformation of liquid into vapor is realized for a small amount of liquid. This makes it possible to apply the isochoric process of superheating saturated steam. A small amount of liquid is compressed and heated isobarically to saturation temperature. Further, it is supplied in sprayed form to a vertically located surface, the temperature of which, in relation to the supplied liquid, is higher. In this case, the liquid instantly turns into saturated vapor. A surface continuously heated by a hot heat source is placed in a closed volume. It is equipped with valves that regulate the moment and quantity of liquid injected, as well as the final pressure and superheat temperature of the steam. The performance and efficiency of the proposed hydrodynamic method for steam generation with an isochoric process of its overheating has been tested using the example of a thermodynamic cycle of a steam turbine plant with an intermediate overheating of steam with a power of 20000 kW. The initial data on the parameters of the steam entering the turbine blades: pressure 10 MPa, temperature 510 °С, temperature of the intermediate overheating of the steam 500 °С, condensation pressure 0.005 MPa. Comparative calculations have shown that the proposed cycle in terms of the main technical and economic indicators significantly exceeds the classical cycle of steam turbine plants widely used in practice. In addition to numerical indicators that positively characterize the proposed cycle, its design and operational indicators also testify in its favor. So, it lacks a large, massive and structurally complex steam boiler; a more thermodynamically efficient isochoric steam superheating process is used.

References

Lavrenchenko G. K., Slinko A. G., Boychuk A. S., Halkin V. M., Kozlovskyi S. V. (2023). Improved thermodynamic cycle of a steam turbine plant. Journal of Chemistry and Technologies, 31(1), 178–185.

https://doi.org/10.15421/jchemtech.v31i1.274768

Seliverstov V. M. (1973). [Heat recovery in marine diesel installations]. L.:Publishing House "Shipbuilding". (In Russian).

Xingping, S., Jintao, S., Qing, H., Yixue, L., Hailun, F., Shuangshuang, C. (2023). A novel liquefied air energy storage system with solar energy and coupled Rankine cycle and sea-water desalination. Journal of Energy Storage, 61, 106759.

https://doi.org/10.1016/j.est.2023.106759

Xuanang, Z., Xuan, W., Jinwen, C., Rui, W., Xingyan, B., Jingyu, W., Hua, T., Gequn, S. (2023). Selection maps of dual-pressure organic Rankine cycle configurations for engine waste heat recovery applications. Applied Thermal Engineering, 228, 120478.

https://doi.org/10.1016/j.applthermaleng.2023.120478

Van, N. N., Nguyen, D. K. P., Xuan, Q. D., Viet D. T., Minh, T. P., Sakthivel, R., Xuan, T. C., Thanh, H. T. (2023). Combination of solar with organic Rankine cycle as a potential solution for clean energy production. Sustainable Energy Technologies and Assessments, 57, 103161.

https://doi.org/10.1016/j.seta.2023.103161

Christoph, L., Andreas, G., Frank, E., Matthias, N. (2022). Experimental results of a low-pressure steam Rankine cycle with a novel water lubricated radial inflow turbine for the waste heat utilization of internal combustion engines. Energy Conversion and Management, 271, 116265.

https://doi.org/10.1016/j.enconman.2022.116265

Habibollahzade, A., Petersen, K. J., Aliahmadi, M., Fakhari, I., Brinkerhoff, J. R. (2022). Comparative thermoeconomic analysis of geothermal energy recovery via super/transcritical CO2 and subcritical organic Rankine cycles. Energy Conversion and Management, 251, 115008.

https://doi.org/10.1016/j.enconman.2021.115008

Montaser, M, Sumsun, N., Mohamad, R., Mohammad, A. A., Hadi, J., Abdul-Ghani, O. (2023). Investigation of a ground-cooled organic Rankine cycle for waste heat recovery. International Journal of Thermofluids, 18, 100348.

https://doi.org/10.1016/j.ijft.2023.100348

Alibakhsh, K., Armin, S., Bardia, J. (2022). Combinations of Ran-kine with ejector refrigeration cycles: Recent progresses and outlook. Applied Thermal Engineering, 211, 118382.

https://doi.org/10.1016/j.applthermaleng.2022.118382

Hai-Xiao, W., Biao, L., Yu-Ting, W. (2023). Simulations on organic Rankine cycle with quasi two-stage expander under cross-seasonal ambient conditions. Applied Thermal Engineering, 222, 119939.

https://doi.org/10.1016/j.applthermaleng.2022.119939

Özkan, K., Yıldız, K., Hüseyin, Y. (2022). Is Kalina cycle or organic Rankine cycle for industrial waste heat recovery applications? A detailed performance, economic and environment based comprehensive analysis. Process Safety and Environmental Protection, 163, 421–437.

https://doi.org/10.1016/j.psep.2022.05.041

Tailu, L., Xuelong, L., Haiyang, G., Xiang, G., Nan, M. (2023). Experimental investigation on organic Rankine flash cycle with high- and low-stage scroll-expanders for thermal power generation. Applied Thermal Engineering, 224, 120082.

https://doi.org/10.1016/j.applthermaleng.2023.120082

Lemmon, E. W, Huber, M. L, McLinden, M. O. (2007). NIST Reference Fluid Thermodynamic and Transport Properties. REFPROP, Version 8.0. Gaithersburg.

Xiaoli, M., Xudong, Z., Yufeng, Z., Kaixin, L., Hui, Y., Jing, L., Yousef, G. A., Haowen, L., Zhonghe, H., Zhijian, L. (2022). Combined Rankine Cycle and dew point cooler for energy efficient power generation of the power plants - A review and perspective study. Energy, 238, Part A, 121688.

https://doi.org/10.1016/j.energy.2021.121688

Guillermo, V. O., Andres, P. C., Dora, V. C. (2023). Assessing sustainable operational conditions of a bottoming organic Rankine cycle using zeotropic mixtures: An energy-emergy approach. Heliyon, 9(1), e12521.

https://doi.org/10.1016/j.heliyon.2022.e12521

Mikheev M. A., Mikheeva I. M. (1973). [Fundamentals of heat transfer]. M.: "Energy" (In Russian).

Zagoruiko V. O., Golikov O. A. (2002). Ship refrigeration equipment. Kiev:"Naukova Dumka" (In Russian).

Coriolano, S., Ambra, G., Hiyam, F. (2023). On the possibility of using an industrial steam turbine as an air expander in a Compressed Air Energy Storage plant. Journal of Energy Storage, Volume 55, Part A, 105453.

https://doi.org/10.1016/j.est.2022.105453

Ohji, A., Haraguchi, M. (2022). 2 - Steam turbine cycles and cycle design optimization: the Rankine cycle, thermal power cycles, and integrated gasification-combined cycle power plants. Advances in Steam Turbines for Modern Power Plants (Second Edition) Woodhead Publishing Series in Energy, 11–40.

https://doi.org/10.1016/B978-0-12-824359-6.00020-2

Roberto, C., Lorena, G. (2021). Regenerative gas turbines and steam injection for repowering combined cycle power plants: Design and part-load performance. Energy Conversion and Management, 227, 113519.

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).