ADHESION STRENGTH OF ELECTRODEPOSITED METAL FILMS WITH METAL SUBSTRATES

DOI:

https://doi.org/10.15421/jchemtech.v31i3.285916Keywords:

bond energy; adhesive strength; electrolytic coatings; coating-substrate boundaryAbstract

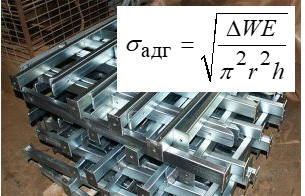

The paper considers the adhesive strength of electrodeposited coatings of nickel, iron, copper and zinc on copper and steel substrates. To determine the theoretical values of adhesive strength, a theoretical approach to determining the adhesive strength at the metal-metal interface is proposed. Based on the analysis of the adhesion mechanism and the nature of the contact interaction, the authors obtained an analytical expression for calculating the adhesive strength values for certain pairs of metals, however, finding the exact value of a number of quantities included in this expression, for example, the specific binding energy and elastic modulus, presents great difficulties. The calculation of the energy of interaction between the atoms of the coating and the substrate was carried out by the method of density functional theory. As a result, the theoretical values of the adhesive strength of nickel, iron, copper, and zinc electrodeposited coatings on copper and steel substrates were obtained, which are in good agreement with the experimental values of the adhesive strength. However, the existing discrepancies between theoretical and experimental data are caused by certain difficulties in finding the specific binding energy and elastic modulus, which are associated with the complexity of modeling the real structure of both the film and the substrate. Finding solutions to these issues will be the subject of further research.

References

Qiaolei, L., Peng S., Kaiyue L., Weifan H., Wenhao D., Taihong H. (2018). Enhanced interface adhesion by in-situ oxidation within metal-ceramic coatings. Ceramics International, 44(18), 23273–23278. https://doi.org/10.1016/j.ceramint.2018.08.332

Santiago, J. A., Fernández-Martínez, I., Wennberg, A., Molina-Aldareguia, J. M., Castillo-Rodríguez, M., Rojas, T. C., Sánchez-López, J. C., González, M. U., García-Martín, J. M. (2018) Adhesion enhancement of DLC hard coatings by HiPIMS metal ion etching pretreatment. Surface and Coatings Technology, 349, 787–796. https://doi.org/10.1016/j.surfcoat.2018.04.090

Kedong, Z., Chuang, Z., Haishan, L., Bangzhu, D., Xuhong, G., Yayun, L. (2022). Study on the substrate surface micro-texturing/carburizing regulating the film-substrate adhesion and wear behavior of DLC coatings. Diamond Relat. Mater., 130, 109535. https://doi.org/10.1016/j.diamond.2022.109535

Klymenko, A., Sytar, V., Kolesnyk, I. (2014). Adhesion of poly (m-, p-phenylene isophtalamide) coatings to metal substrates. Prog. Org. Coat. 77(11), 1597–1602. https://doi.org/10.1016/j.porgcoat.2014.04.028

Shuai, X., Zhuo, Z., Yanwen, Z., Dongxu, C., Kaice, Z., Tong, L., Yangtao, Z., Aihuai, W. (2023). Interface feature via key factor on adhesion of CrN multilayer and alloy substrate. Applied Surface Science, 630, 157492. https://doi.org/10.1016/j.apsusc.2023.157492

Oleksandrenko, V.P., Svidersjkyj, V.P., Kyrychenko, L. M., Jefimenko, V. V. (2021). Vplyv skladu i tekhnologhichnykh faktoriv na adghezijnu micnistj ftoroplastovykh pokryttiv do metalevykh poverkhonj. Visnyk Khmeljnycjkogho nacionaljnogho universytetu, 301(5), 45–51. https://doi.org/10.31891/2307-5732-2021-301-5-45-51

Ciavarella, M., Joe, J., Papangelo, A., Barber, J. R. (2019). The role of adhesion in contact mechanics. Journal of the royal society interface, 16(151). https://doi.org/10.1098/rsif.2018.0738

Panteleenko, F.I., Karpets, M.N., Belotserkovsky, M.A., Sosnovsky, A.V. (2021). Determination of Adhesive and Cohesive Strength in Metal Coatings Deposited by Hypersonic Metallization. Science & Technique, 20(6), 459–464. https://doi.org/10.21122/2227-1031-2021-20-6-459-464

Escobar Galindo, R., Veen, A. van, Schut, H., Janssen, G. C. A. M., Hoy, R., de Hosson, J. Th. M. (2005). Adhesion behaviour of CrNx coatings on pre-treated metal substrates studied in situ by PBA and ESEM after annealing. Surface and Coatings Technology, 199(1), 57–65. https://doi.org/10.1016/j.surfcoat.2005.04.018

Yudhanto, A., Li, X., Tao, R., Melentiev, R., Lubineau, G. (2023). Identifying adhesion characteristics of metal-polymer interfaces: Recent advances in the case of electroplated acrylonitrile butadiene styrene. Mater. Today Commun., 35, 1–10. https://doi.org/10.1016/j.mtcomm.2023.106218

Watanabe, Y., Fujisawa, S., Yonezu, A., Chen, X. (2016) . Quantitative evaluation of adhesion quality of surface coating by using pulse laser-induced ultrasonic waves. Surface and Coatings Technology, 286, 231–238. https://doi.org/10.1016/j.surfcoat.2015.12.026

Pedrolli, О., Nadimi, S., Maramizonouz, S., Achiaga Menor, B., López, A. (2023). Kinetic adhesion test to determine particle surface energy. HardwareX., 14, e00437. https://doi.org/10.1016/j.ohx.2023.e00437

González-Tortuero, S., Garrido, M. A., Rodríguez, J. (2023). An adhesion study in Ni and Cu nanocontacts from a molecular dynamics perspective. European Journal of Mechanics – A. Solids, 99, 104942. https://doi.org/10.1016/j.euromechsol.2023.104942

Yasuda, S., Miyagawa, T., Yonezu, A., Ishibashi, K. (2023). Laser shock-wave adhesion test (LaSAT) and ab initio calculations for adhesive strength evaluation of thin metallic films. Mater. Today Commun., 35, 106237. https://doi.org/10.1016/j.mtcomm.2023.106237

Miraz, A. S. M., Sun, S., Shao, S., Meng, W. J., Ramachandran, B. R., Wick, C. D. (2019). Computational study of metal/ceramic interfacial adhesion and barrers to shear displacement. Comput. Mater. Sci., 168, 104–115.https://doi.org/10.1016/j.commatsci.2019.06.006

Chen, L. H., Rigney, D. A. (1990). Adhesion theories of transfer and wear during sliding of metals. Wear, 136(2), 223–235. https://doi.org/10.1016/0043-1648(90)90148-4

Roman, T., Agerico Diño, W., Nakanishi, H., Kasai, H., Miyako, Y., Naritomi, M. (2004). PPS-metal adhesion: a density functional theory-based study. Solid State Commun., 132(6), 405–408. https://doi.org/10.1016/j.ssc.2004.07.073

Zabludovsky, V. A., Shtapenko, E. Ph., Gribok, V. S.,Ganitsh, R. Ph., Gulivets, A. N., Gadgilov, M. V. (2000). The Application of Program-Controlled Pulsed Current for Obtaining Metallic Coatings with Specific Properties. Trans. IMF., 78(3), 110-112. https://doi.org/10.1080/00202967.2000.11871320

Parr, R. G., Yang Density, W. (1989). Functional Theory of Atoms and Molecules. Oxford University Press, N. Y. https://doi.org/10.1002/qua.560470107

Fatima, Y. L., Sara, A. T., Luis, A. R. P., Wenjie, X., Chapter, O. (2023). Electronic structure and density functional theory. Fundamentals of Multiscale Modeling of Structural Materials, 3–35. https://doi.org/10.1016/B978-0-12-823021-3.00007-5

Mei, G., Bhattacharya, S., Yacout, A. M. (2019). Adhesion of ZrN and Al2O3 coatings on U metal from first-principles. Applied Surface Science, 473, 121–126. https://doi.org/10.1016/j.apsusc.2018.12.111

Jia, Z., Zhao, X., Zhang, G., Kang, Y., Xu, H., Zhao, Z. (2022). A comparable study of Fe/Cu interfaces by first-principles method: The surface energy, work of adhesion and electronic structures. Physica B: Condensed Matter, 646, 414348. https://doi.org/10.1016/j.physb.2022.414348

Alexei, V., Arbuznikov, Martin Kaupp. (2007). Local hybrid exchange-correlation functionals based on the dimensionless density gradient. Chem. Phys. Lett., 440(1-3), 160–168. https://doi.org/10.1016/j.cplett.2007.04.020

Matczak, P. (2012). Assessment of B3LYP combined with various ECP basis sets for systems containing Pd, Sn, and Pb. Computational and Theoretical Chemistry, 983, 25–30. https://doi.org/10.1016/j.comptc.2011.12.023

Schreckenbach, G., Hay, P. J., Martin, R. L. (1999). Density Functional Calculations on Actinide Compounds. Survey of Recent Progress and Application to [UO2X4]2 – (X = F, Cl, OH) and AnF6 (An = U, Np, Pu). J. Comput. Chem., 20, 70. https://doi.org/10.1002/(SICI)1096-987X(19990115)20:1<70::AID-JCC9>3.0.CO;2-F

Claude, N. N. S., Jean, M. O., Idrice, A. A., Désiré, B. M. (2023). Mononuclear half-sandwich nd7 metallo drug complexes based on bidentate N∩N dendritic scaffolds: DFT (B3LYP; BP86 and B3PW91) examination. Journal of Molecular Graphics and Modelling, 120, 108417. https://doi.org/10.1016/j.jmgm.2023.108417

Lee, C., Yang, W., Parr, R. G. (1988). Development of the Colle – Salvetti correlation – energy formula into a functional of the electron density. Phys. Rev. B, 37, 785. https://doi.org/10.1103/PhysRevB.37.785

Miehlich, B., Savin, A., Stoll, H., Preuss, H. (1989). Results obtained with the correlation – energy density functionals of Becke and Lee, Yang and Parr. Chem. Phys. Lett., 157, 200. https://doi.org/10.1016/0009-2614(89)87234-3

Keire, D. A., Jang, Y. H., Lin, L., Dasgupta, S., Goddard, W. A., Shively, J. E. (2001). Chelators for Radioimmunotherapy. Inorg. Chem., 17(40), 4310. https://doi.org/10.1021/ic00235a031

Kraiev, M., Voronkov, E., Kraieva, V. (2021). Calculation of energy and magnetic susceptibility of Fe atomic system during dislocation motion in magnetic field. Multidiscip. Model. Mater. Struct., 17(6), 1183–1192. https://doi.org/10.1108/MMMS-02-2021-0026

Tytarenko, V. V., Shtapenko, E. Ph., Voronkov, E. О., Zabludovsky, V. A., Kolodziejczyk, W., Kapusta, K., Kuznetsov, V. N. (2021). Quantum mechanical modeling of the interaction of carbon nanostructures with metal ions. J. Surf. Invest.: X-Ray, Synchrotron Neutron Tech., 15(4), 866–871. https://doi.org/10.1134/S102745102104039X

Shalashilin, D. V., Makhov, D. V. (2022). Gaussian Wave Packet and Coherent State Based Methods in Chemical Quantum Dynamics. Reference Module in Chemistry, Molecular Sciences and Chemical Engineering. https://doi.org/10.1016/B978-0-12-821978-2.00026-X

Tang, Z., Gui, X., Fei, W. (2011). Utilization of Molecular Simulation Software Gaussian 03 to Design Absorbent for CO2 Capture. Procedia Eng., 12, 87–92. https://doi.org/10.1016/j.proeng.2011.05.015

Shtapenko, E. P., Zabludovsky, V. O., Tytarenko, V. V., Kraeva, V. S., Afanasov, A. М. (2019). Formation of layered structure in films of nickel at electrodeposition by a pulse current. Metallofizika i Noveishie Tekhnologii. 1(41), 27. https://doi.org/10.15407/mfint.41.01.0027

Shtapenko, E. F., Zabludovsky, V. A., Tytarenko, V. V. (2018). Diffusion at the Film-Substrate Interface during Nickel Electrocrystallization on a Copper Substrate. J. Surf. Invest.: X-Ray, Synchrotron Neutron Tech., 2(12), 377. https://doi.org/10.1134/S1027451018020362

Tytarenko, V. V., Zabludovsky, V. A., Shtapenko, E. Ph., Tytarenko, I. V. (2022). Kinetic regularities of the formation of composite electrolytic coatings containing ultradispersed diamond particles. Physics and Chemistry of Solid State, 23(3), 461–467. https://doi.org/10.15330/pcss.23.3.461-467

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).