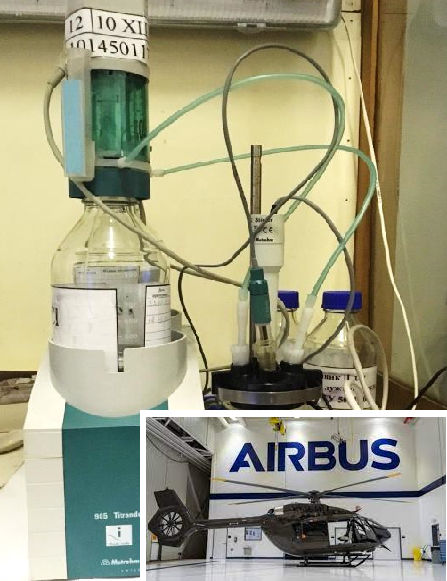

CHANGE IN THE MAIN INDICATORS OF OIL QUALITY IN THE OPERATION OF «AIRBUS HELICOPTERS H-145» HELICOPTERS

DOI:

https://doi.org/10.15421/jchemtech.v31i3.286038Keywords:

synthetic oil Mobil Jet Oil 254; mineral oil MK-8P; quality indicators; kinematic viscosity; total alkalinity number; additives; Airbus Н-145 Helicopter.Abstract

The operating conditions of synthetic Mobil Jet Oil 254 and mineral MK-8P oil in the turboprop engines of Airbus Н-145 helicopters were analyzed. The study showed that the temperature in the nodes of the mechanisms can reach

150-200 °C during operation, which leads to changes in the physico-chemical and operational indicators of the quality of lubricating materials. The dynamics of changes of the kinematic viscosity and the total base number was studied. The change in kinematic viscosity for 300 h of oils’ working time in the helicopter at the standard measurement temperature of 100 °C is shown. It is about 5 % for synthetic Mobil Jet Oil 254 and more than 18 % for mineral oil MK-8P. The change of kinematic viscosity at the negative standard temperature of its measurement (-40 °С) is less dependent on temperature for synthetic oil than for mineral oil. This makes Mobil Jet Oil 254 more attractive for lubricating engine mechanisms from a tribological point of view. The study showed that the base number of mineral oil MK-8P decreases by almost 50 % with increasing service life up to 300 hours and falls more sharply than synthetic Mobil Jet Oil 254, which indicates the deterioration of additives in it.

According to the performed research, it is not recommended to use MK-8P mineral oil in the lubrication system of Airbus Helicopters Н-145, as the oil is not suitable for a long time to maintain the main quality indicators when operation in the reducer. Research on changes in the quality of oils in the process of their real operation in the lubrication system of helicopters is relevant in terms of providing recommendations on the timing of their replacement.

References

Rostek, E., Babiak, M. (2019). The experimental analysis of engine oil degradation utilizing selected thermoanalytical methods. Transportation Research Procedia, 40, 82–89. https://doi.org/10.1016/j.trpro.2019.07.014.

Bushell, K. W. (2003). Jet and Gas Turbine Engines. In R. A. Meyers Encyclopedia of Physical Science and Technology. New York, USA: Academic Press.

Wierzbicka, N., Szadkowska, D., Patalas, A., Talar, R., Łabudzki, R., Zawadzki, P. (2020). Evaluation of deterioration of engine oil properties in the function of mileage. J. Phys. Conf. Ser., 1426, 012004. https://doi.org/10.1088/1742-6596/1426/1/012004.

Hu, E., Liu, T., Song, R., Dearn, K., Xu, Y. (2013). Effect of TiF3 catalyst on the tribological properties of carbon black-contaminated engine oils. Wear., 305, 166–176. https://doi.org/10.1016/j.wear.2013.06.003.

Wolak, A., Zając, G. (2019). An Empirical Study of the Variables Affecting the Frequency of Engine Oil Change in the Environmental Aspect. Rocznik Ochrona Srodowiska. 21, 738–766.

Idzior, M. (2021) Aging of engine oils and their influence on the wear of an internal combustion engine. Combustion Engines. 185(2), 15–20. https://doi.org/10.19206/CE-138033.

Khamidullaevna, A.Z., Siddikov, F. (2022). The aging process of motor oils during operation. European international journal of multidisciplinary research and management studies. 2(6), 166–169. https://doi.org/10.55640/eijmrms-02-06-32.

Cai, Z. B., Zhou, Y., Qu, J. (2015). Effect of oil temperature on tribological behavior of a lubricated steel−steel contact. Wear., 332–333, 1158–1163. https://doi.org/10.1016/j.wear.2015.01.064.

Martini, A., Ramasamy, U.S., Len, M. (2018). Review of Viscosity Modifier Lubricant Additives. Tribol Lett. 66, 58. https://doi.org/10.1007/s11249-018-1007-0.

Thong, D., Hutchinson, P.A., Wincierz, C., Schimmel, T. (2014). Viscosity Modifiers. In: Mang, T. Encyclopedia of Lubricants and Lubrication. Berlin, Germany: Springer.

Méheust, H., Le Meins, J.-F., Grau, E., & Cramail, H. (2021). Bio-Based Polyricinoleate and Polyhydro-xystearate: Properties and Evaluation as Viscosity Modifiers for Lubricants. ACS Applied Polymer Materials. 3(2), 811–818. https://doi.org/10.1021/acsapm.0c01153.

Syabilah, S., Amit, R. N., Mohd, H. A., Zulkifli, N.W.M., Mohd, R. J., Wageeh, A. Y., Lee H. V. (2021). Semicarbazide and thiosemicarbazide containing butylated hydroxytoluene moiety: new potential antioxidant additives for synthetic lubricating oil. RSC Adv. 11(13), 7138–7145. https://doi.org/10.1039/d0ra10626g.

Alimova, Z. Kh., Abdurazzoqov, A. A., Yuldasheva, G. B. (2022). Improving the Anticorrosive Properties of Motor Oils by Adding Additives. Texas Journal of Engineering and Technology. 8, 16–19.

Nassar, A. M., Ahmed, N. S., Abdel-Hameed, H. S., El-Kafrawy, A. F. (2016). Synthesis and utilization of non-metallic detergent/dispersant and antioxidant additives for lubricating engine oil. Tribology International. 93, 297–305. https://doi.org/10.1016/j.triboint.2015.08.033.

Jiang, H., Hou, X., Ma, Y., Guan, W., Liu, H., Qian, Y. (2022). Elaboration of Ionic Liquids on the Anti-Wear Performance of the Reinforced Steel-Steel Contact Surface. Lubricants. 10, 260. https://doi.org/10.3390/lubricants10100260.

Hu, C., You, G., Liu, J., Du, S., Zhao, X., Wu, S. (2021). Study on the mechanisms of the lubricating oil antioxidants: Experimental and molecular simulation. Journal of Molecular Liquids. 324, 115099. https://doi.org/10.1016/j.molliq.2020.115099.

Airbus H145 helicopters https://www.airbus.com/en/products-services/helicopters/civil-helicopters/h145.

Sadineni, A., Ivvala, J., Sai, S. (2017). A review on the importance of viscosity in engine oils. Journal of Mechanical and Production Engineering (JMPE), 7(1). 10.

Wolak, A., Zając, G., Słowik, T. (2021). Measuring Kinematic Viscosity of Engine Oils: A Comparison of Data Obtained from Four Different Devices. Sensors. 21. 2530. https://doi.org/10.3390/s21072530.

Sikora, G., Miller, H. (2012). The analysis of changes in total base number and the flash point in the exploited engine oil. Journal of KONES Powertrain and Transport. 19(3), 395–398.

Wolak, A. (2018). TBN performance study on a test fleet in real-world driving conditions using present-day engine oils. Measurement. 114. 322–331. https://doi.org/10.1016/j.measurement.2017.09.044.

Chikunova, A.S., Vershinin, V.I. (2021). Determining the Total Base Number of Engine Oils Using Potentiometric Titration. Inorg Mater., 57, 1440–1446. https://doi.org/10.1134/S002016852114003X.

State Committee for Technical Regulation and Consumer Policy of Ukraine. (2008). [National standardization basic principles]. (DSTU 5094:2008). Kyiv, Derzhpozhyvstandart Ukraine (in Ukrainian).

ASTM International. (2015). ASTM D2896-15. Standard Test Method for Base Number of Petroleum Products by Potentiometric Perchloric Acid Titration.

ASTM International (2017). ASTM D4739-17, Standard Test Method for Base Number Determination by Potentiometric Hydrochloric Acid Titration.

Yefymenko V., Kalmykova N., Kravchuk T. (2022). Oils for gas turbine engines of «Airbus Helicopters H-145». The ХVIII International Scientific and Practical Conference «Advancing in research, practice and education», Florence, Italy, 585–590.

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).