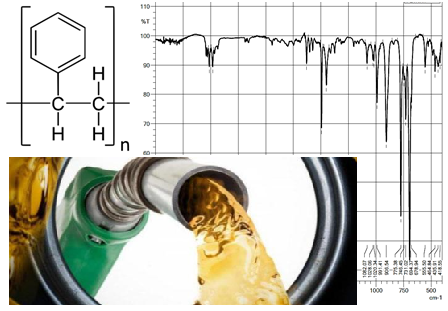

PERSPECTIVES OF LOW-TEMPERATURE ATMOSPHERIC PRESSURE CATALYTIC DECOMPOSITION OF POLYSTYRENE

DOI:

https://doi.org/10.15421/jchemtech.v32i2.286999Keywords:

plastic waste; chemicals pollution; catalytic cracking; polystyrene; modified zeolite; Ni-modified catalysts.Abstract

Plastic pollution has become one of the global environmental threats to humans and the whole world. Plastics do not exist without the chemicals that emitted at every stage of their life cycle – from oil extraction to production, and disposal, especially when plastic waste is not disposed properly, but rather stored in the open air on unprotected soil near water sources. Chemical recycling of plastic waste, which is based on catalytic cracking, prevents the emission of toxic chemicals into the environment; produces liquid oils and additives for various fuels; and avoids significant energy costs using mechanical and thermal processing methods. Catalytic cracking of plastics in the presence of natural and synthetic zeolite catalysts allows to produce a wide range of aromatic hydrocarbons. The modified samples of CaY-based catalysts were used in the catalytic cracking of polystyrene, as a type of thermoplastic polymer. Depending on the selected type of zeolite catalyst (ZSM-5, Ni-ZSM-5, USY, NiHY), the practical yield the components of the liquid fraction was determined, as follows: styrene, styrene dimer, styrene trimer, ethylbenzene, methylstyrene, cumene, and others. The yield of styrene using ZSM-5 is 42 %, at Ni-ZSM-5 – 5.97 %, at USY – 1.26 %, at NiHY – 47.37 %. The yield of the liquid fraction at ZSM-5 is 67.2 %, at Ni-ZSM-5 – 38.5 %, at USY – 15 %, at NiHY – 70.3 %. According research results, it was found that the most selective and effective catalyst (among the above) for polystyrene cracking was a nickel-modified alumosilicate (NiHY). The yield of the liquid fraction using the NiHY catalyst is 70.3 %, and the yield of styrene is 47.37 %. In conclusion, the further development of catalysts is necessary to improve the selectivity and efficiency of low-temperature catalytic cracking reactions to obtain secondary raw materials for the synthesis of polystyrene.

References

Everything you need to know about plastic pollution. UN Environment programme. (2023). https://www.unep.org/news-and-stories/story/everything-you-need-know-about-plastic-pollution

Williams, A. T., Rangel-Buitrago, N. (2022). The past, present, and future of plastic pollution. Mar. Pollut. Bull., 176, 113429. https://doi.org/10.1016/j.marpolbul.2022.113429

Hou, Q., Zhen, M., Qian, H., Nie, Y., Bai, X., Xia, T., Rehman, M. L. U., Li, Q., Ju, M. (2021). Upcycling and catalytic degradation of plastic wastes. Cell Rep., 2(8), 100514. https://doi.org/doi:10.1016/j.xcrp.2021.100514

Yanushevska, O., Dontsova, T., Krymets, G., Kyrii, S., Krasuliak, O., Dorozhko, K. (2023). Prospects for the Catalytic Conversion of Plastic Waste. In: Fesenko, O., Yatsenko, L. (eds) Nanooptics and Photonics, Nanochemistry and Nanobiotechnology, and Their Applications. Springer Proceedings in Physics, Springer, Cham., 280, 73–82. https://doi.org/10.1007/978-3-031-18104-7_5

Kyrii, S., Dontsova, T., Karaschuk, O., Yanushevska, O. (2023). State of the Art of Microplastic and Nanoplastic Pollution: Origin and Removal Methods. Springer Proceedings in Physics, Springer, Cham., 279, 229–241. https://doi.org/10.1007/978-3-031-18096-5_12

Ho, B.T., Roberts, T.K., Lucas, S. (2018). An overview on biodegradation of polystyrene and modified polystyrene: the microbial approach. Crit. Rev. Biotechnol., 38(2), 308–320. https://doi.org/10.1080/07388551.2017.1355293

Marquez, C., Martin, C., Linares, N., Vos, D. (2023). Catalytic routes towards polystyrene recycling. Mater. Horiz., 10(1). https://doi.org/10.1039/D2MH01215D

Dong, D., Guo, Z., Yang, X., Dai, Y. (2024). Comprehensive understanding of the aging and biodegradation of polystyrene-based plastics. Environ Pollut. 342, 123034. https://doi.org/10.1016/j.envpol.2023.123034

Xu, L., Li, Z., Wang, L., Xu, Z., Zhang, S., Zhang, Q. (2024). Progress in polystyrene biodegradation by insect gut microbiota. World J Microbiol Biotechnol. 40(5), 143. https://doi.org/10.1007/s11274-024-03932-0

Mor, R., Sivan, A. (2008). Biofilm formation and partial biodegradation of polystyrene by the actinomycete Rhodococcus ruber: biodegradation of polystyrene. Biodegradation, 19(6), 851–858. https://doi.org/10.1007/s10532-008-9188-0

Huang, Z., Shanmugam, M., Liu, Z., Brookfield, A., Bennett, E.L., Guan, R., Vega Herrera, D.E., Lopez-Sanchez, J.A., Slater, A.G., McInnes, E.J. L., Qi, X., Xiao, J. (2022). Chemical Recycling of Polystyrene to Valuable Chemicals via Selective Acid-Catalyzed Aerobic Oxidation under Visible Light. JACS, 144(14), 6532–6542. https://doi.org/10.1021/jacs.2c01410

Cao, R., Zhang, MQ., Hu, C., Xiao, D., Wang, M., Ma, D. (2022). Catalytic oxidation of polystyrene to aromatic oxygenates over a graphitic carbon nitride catalyst. Nat. Commun., 13, 4809. https://doi.org/10.1038/s41467-022-32510-x

Thambiyapillai, S., Ramanujam, M. (2021). An Experimental Investigation and Aspen HYSYS Simulation of Waste Polystyrene Catalytic Cracking Process for the Gasoline Fuel Production. Int. Journal of Renewable Energy Development, 10(4), 891–900. https://doi.org/10.14710/ijred.2021.33817

Gonzalez-Aguilar, A.M., Pérez-García, V., Riesco-Ávila, J.M. (2023). A Thermo-Catalytic Pyrolysis of Polystyrene Waste Review: A Systematic, Statistical, and Bibliometric Approach. Polymers, 15, 1582. https://doi.org/10.3390/polym15061582

Joshi, B., Raghav, H., Agrawal, A., Vempatapu, B.P., Ray, A., Sarkar, B. (2023). Sustainable production of styrene from catalytic recycling of polystyrene over potassium promoted Fe–Al2O3 catalyst. Sustainable Energy Fuels, 7(5), 1256–1264. https://doi.org/10.1039/D2SE01584F

Wang, J., Jiang, J., Sun, Y., Zhong, Z., Wang, X., Xia, H., Liu, G., Pang, S., Wang, K., Li, M., Xu, J., Ruan, R., Ragauskas, A.J. (2019). Recycling benzene and ethylbenzene from in-situ catalytic fast pyrolysis of plastic wastes. Energy Convers. Manag., 200, 112088. https://doi.org/10.1016/j.enconman.2019.112088

Miandad, R., Rehan, M., Barakat, M.A., Aburiazaiza, A.S., Khan, H., Ismail, I.M., Dhavamani, J., Gardy, J., Hassanpour, A., Nizami, A.-S. (2019). Catalytic pyrolysis of plastic waste: Moving towards pyrolysis based biorefineries. Front. Energy res., 7(27). https://doi.org/10.3389/fenrg.2019.00027

Rehan, M., Miandad, R., Barakat, M.A., Ismail, I.M.I., Almeelbi, T., Gardy, J., Hassanpour, A., Khan, M.Z., Demirbas, A., Nizami, A.S. (2017). Effect of zeolite catalysts on pyrolysis liquid oil. Int. Biodeterior. Biodegradation, 119, 162–175. https://doi.org/10.1016/j.ibiod.2016.11.015

Lerici, L. C., Renzini, M.S., Pierella, L.B. (2015). Chemical Catalyzed Recycling of Polymers: Catalytic Conversion of PE, PP and PS into Fuels and Chemicals over H-Y. Procedia Materials Science, 8, 297–303. https://doi.org/10.1016/j.mspro.2015.04.076

Dahal, R., Uusi-Kyyny, P., Pokki, J.-P., Ohra-aho, T., Alopaeus, V. (2023). Conceptual design of a distillation process for the separation of styrene monomer from polystyrene pyrolysis oil: experiment and simulation. Chem. Eng. Res. Des., 195, 65–75. https://doi.org/10.1016/j.cherd.2023.05.039

Angelopoulou, P.P., Stathouraki, M.-M., Keum, J. K., Hong, K., Avgeropoulos, А., Sakellariou, G. (2023). Synthesis and morphological characterization of linear and miktoarm star poly (solketal methacrylate)-block-polystyrene copolymers, Eur. Polym. J., 190, 111995. https://doi.org/10.1016/j.eurpolymj.2023.111995

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).