ANTIBACTERIAL PROPERTIES OF CERAMIC MEMBRANES WITH TiO2 SELECTIVE LAYER

DOI:

https://doi.org/10.15421/jchemtech.v32i2.298738Keywords:

сeramic matrix, membrane, selective layer, bacterial contamination, antibacterial properties, titanium(IV) oxideAbstract

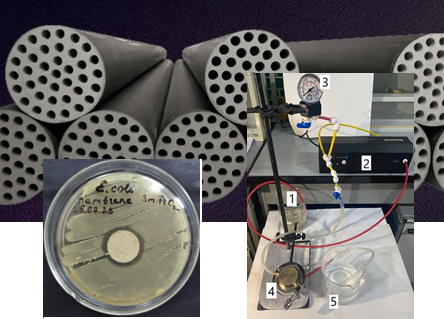

The use of ceramic membranes is an effective way to reduce microbial contamination of water without chemicals. Ceramic membranes have a longer service life and more environmentally friendly disposal methods. Creating inexpensive ceramic membranes significantly reduces the load on fine filtration installations, which is especially important for the pharmaceutical, biotechnological and food industries. The aim of the work was to manufacture ceramic membranes of asymmetric configuration based on a matrix and a TiO2-containing selective layer and to investigate the ability of ceramic matrices/membranes to reduce turbidity, chemical oxygen demand and the level of microbial pollution. Two samples of ceramic membrane matrices were synthesized: CM-1 based on aluminium oxide, silicon carbide, borax, ammonium carbonate, and CM-2 based on kaolin, silicon carbide, borax, ammonium bicarbonate and silicon oxide. Various selective coatings were applied to the ceramic matrices by the spin-coating method. To determine and compare the characteristics of the obtained ceramic matrices/membranes, the raw (natural) and purified water were analyzed for the presence of suspended solids (nephelometric method), chemical oxygen demand (photometric method) and the level of microbial contamination (CFU/mL). The antibacterial properties of ceramic membranes were evaluated using the zone of inhibition test, namely the diffusion method in agar. Features of membrane morphology were also studied using scanning electron microscopy. It was determined that the turbidity, chemical oxygen consumption and microbial contamination of the treated water after filtration were reduced. The CM-1.10 ceramic membrane with TiO2 selective layer showed greater efficiency in reducing suspended solids contaned and microbiological pollution indicators. The prospect of using ceramic matrices and ceramic membranes with TiO2 selective layer for natural water purification to eliminate bacterial contamination and contamination with organic substances and improve the organoleptic qualities of water has been confirmed.

References

Rashad, D., Amin, Sh.K., Mansour, M.S., Abdallah, H. (2022). Fabrication of low-cost antibacterial microfiltration tubular ceramic membranes. Ceramics International, 48(8), 11489–11501. https://doi.org/10.1016/j.ceramint.2022.01.005

Samadi, A, Gao, L, Kong, L, Orooji, Y, Zhao, S. (2022). Waste-derived low-cost ceramic membranes for water treatment: Opportunities. challenges and future directions, Resources. Conservation and Recycling. 185, 106497. https://doi.org/10.1016/j.resconrec.2022.106497

Asif, M.B, Zhang, Z. (2021). Ceramic membrane technology for water and wastewater treatment: A critical review of performance, full-scale applications, membrane fouling and prospects. Chemical Engineering Journal, 418, 129481. https://doi.org/10.1016/j.cej.2021.129481

Azaman, F., Nor, M.A.A.M., Rafizah Wan, A.W., Razali, M.H, Zulkifli, R.C, Zaini, M.A.A, Ali, A. (2021). Review on natural clay ceramic membrane: Fabrication and application in water and wastewater treatment. Malaysian Journal of Fundamental and Applied Sciences. 17(1), 62–78. https://doi.org/10.11113/mjfas.v17n1.2169

Mountoumnjou, O., Szymczyk, A., Lyonga Mbambyah, E.E., Njoya, D., Elimbi, A. (2022). New Low-Cost Ceramic Microfiltration Membranes for Bacteria Removal. Membranes, 12, 490. https://doi.org/10.3390/membranes12050490

Diana, S., Fauzan, R., Elfiana, E. Removing Escherichia Coli Bacteria in River Water using Ceramic Membrane from Mixed Clay and Fly Ash Material. IOP Conference Series: Materials Science and Engineering, International Conference on Science and Innovated Engineering (I-COSINE), 536, 012089. https://doi.org/10.1088/1757-899X/536/1/012089

Diana, S., Munawar, М., Saifuddin, S., Nahar, N., Silmina, S., Razi, F,. Arahman, N. (2023). Ceramic Membrane-Based on Fly Ash-Clay For River Water Treatment. Biointerface Research in Applied Chemistry. 13(5), 430, 25640944900. https://doi.org/10.33263/BRIAC135.430

Mohit Kumar, C., Roshni, M., Vasanth, D. (2019). Treatment of aqueous bacterial solution using ceramic membrane prepared from cheaper clays: A detailed investigation of fouling and cleaning. Journal of Water Process Engineering. 29, 100797. https://doi.org/10.1016/j.jwpe.2019.100797

Zuo, X., Zhang, Sh., Ma, G., Lv, Y., Li, P. (2020). Analysis of ceramic membrane fouling behavior and cleaning Technology. E3S Web of Conferences ICAEER 2020. 194, 04048. https://doi.org/10.1051/e3sconf/202019404048

Kamgang-Syapnjeu, P., Njoya, D., Kamseu, E., Balme, S. (2022). Bechelany, M., Soussan, L. Bio-Based Ceramic Membranes for Bacteria Removal from Water. Membranes. 12, 901. https://doi.org/10.3390/membranes12090901

da Silva Biron, D., Santos, V., Bergmann, C. P. (2021). Tubular ceramic membranes coated with ZnO and applied in the disinfection of water contaminated with Staphylococcus aureus. Ceramics International, 47(19), 27082–27090. https://doi.org/10.1016/j.ceramint.2021.06.121

Xu, J., Pan, Z., Peng, S., Zhao, Y., Jiang, S., Chen, Y.J., Xie, Z.H., Munroe, P. (2020). Remarkable bactericidal traits of a metal-ceramic composite coating elated by hierarchically structured surface. iScience. 24(1), 101942. https://doi.org/10.1016/j.isci.2020.101942

Zhao, Y., Huang, G., An, Ch., Huang, J., Xin, X., Chen, X., Hong, Y., Song, P. (2020). Removal of Escherichia Coli from water using functionalized porous ceramic disk filter coated with Fe/TiO2 nano-composites. Journal of Water Process Engineering, 33, 101013. https://doi.org/10.1016/j.jwpe.2019.101013

Ugarte, P., Ramo, А., Quílez, J., Bordes, M.C., Mestre, S., Sánchez, E., Peña, J. Á., Menéndez, M. (2022). Low-cost ceramic membrane bioreactor: Effect of backwashing, relaxation and aeration on fouling. Protozoa and bacteria removal. Chemosphere. 306, 135587. https://doi.org/10.1016/j.chemosphere.2022.135587

He, Y., Huang, G., An, Ch., Huang, J., Zhang, P., Chen, X., Xin, Xi. (2018). Reduction of Escherichia Coli using ceramic disk filter decorated by nano-TiO2: A low-cost solution for household water purification. Science of The Total Environment. 616–617:1628–1637. https://doi.org/10.1016/j.scitotenv.2017.10.149

Serhiienko, A., Dontsova, T., Yanushevska, O., Vorobyova, V., Vasyliev, G. (2023). Characterization of ceramic membrane support based on Ukrainian kaolin. Molecular Crystals and Liquid Crystals, 752(1), 128–141. https://doi.org/10.1080/15421406.2022.2091279

Dontsova, T., Kyrii, S., Yanushevska, O., Suprunchuk, V., Kosogina, I. (2022). Physicochemical properties of TIO2, ZrO2, Fe3O4 nanocrystalline adsorbents and photocatalysts. Chemical Papers. 76, 7667–7683. https://doi.org/10.1007/s11696-022-02433-4

Zielińska, M., Galik, M. (2017). Use of Ceramic Membranes in a Membrane Filtration Supported by Coagulation for the Treatment of Dairy Wastewater. Water Air Soil Pollut., 228, 173. https://doi.org/10.1007/s11270-017-3365-x

Amin, Sh.K., Abdullah, H.A.M., Roushdy, M.H., El-Sherbiny, S.A. (2016). An overview of production and development of ceramic membranes. International Journal of Applied Engineering Research. 11, 7708–7721.

Issaoui, M., Limousy, L. (2019). Low-cost ceramic membranes: Synthesis, classifications, and applications. Comptes Rendus Chimie, 22, 175e187. https://doi.org/10.1016/j.crci.2018.09.014

Dommati, H., Sinha Ray, S., Wang, J-Ch., Chen, Sh-Sh. (2019). A comprehensive review of recent developments in 3D printing technique for ceramic membrane fabrication for water purification. RSC Advances, 9, 16869–16883 | 16869. https://doi.org/10.1039/c9ra00872a

Sun, H., Liu, H., Wang, S., Cheng, F., Liu, Y. (2018). Ceramic membrane fouling by dissolved organic matter generated during on-line chemical cleaning with ozone in MBR. Water Research. 146, 328–336. https://doi.org/10.1016/j.watres.2018.09.001

Tomasula, P.M., Mukhopadhyay, S., Datta, N., Porto-Fett, A., Call, J.E., Luchansky, J.B., Renye, J., Tunick, M. (2011). Pilot-scale cross flow microfiltration and pasteurization to remove sporesof Bacillus anthracis (Sterne) from milk. Journal of Dairy Science, 94(9), 4277–4291. https://doi.org/10.3168/jds.2010-3879

Waszak, M., Gryta, M. (2016). The ultrafiltration ceramic membrane used for broth separation in membrane bioreactor. Chemical Engineering Journal. 305, 129–135. https://doi.org/10.1016/j.cej.2015.11.058

Abdullayev, A., Bekheet, M.F., Hanaor, D.A.H., Gurlo, A. (2019). Materials and Applications for Low-Cost Ceramic Membranes. Membranes. 9, 105. https://doi.org/10.3390/membranes9090105

Kuzminchuk, A., Burmak, A., Litynska, M. et al. (2023). New diatomaceous earth and kaolinite ceramic membranes for turbidity reduction in water. Applied Nanoscience. 13, 5335–5343. https://doi.org/10.1007/s13204-023-02792-8

Yanushevska, O. I., Dontsova, T. A., Aleksyk, A. I., Didenko, O. Z., Nypadymka, A. S. (2020). Surface and structural properties of clay materials based on natural saponite. Clays and Clay Minerals. 20(5), 465–475. https://doi.org/10.1007/s42860-020-00088-4

Maryani, E., Nurjanah, N. S., Hadisantoso, E P., Wijayanti, R. B. (2020). The Effect of TiO2 additives on the antibacterial properties (Escherichia coli and Staphylococcus aureus) of glaze on ceramic tiles. IOP Conf. Ser.: Mater. Sci. Eng., 980, 012011. https://doi.org/10.1088/1757-899X/980/1/012011

Boffa, V., Lunghi, C., Quist-Jensen, C.A., Magnacca, G., Calza, P. (2019). Fabrication and surface interactions of super-hydrophobic silicon carbide for membrane distillation. Nanomaterials (Basel). 9(8), 1159. https://doi.org/10.3390/nano9081159

Juan, W., Xiaoyu, W., Qianlong, F., Jinxiu, F., Fengrui, Z., Shuang, L. (2023). Silicon carbide ceramic membrane support sintered at 800 °C with low-temperature sintering aid. Ceramics International. 49(15), 25612–25619. https://doi.org/10.1016/j.ceramint.2023.05.102

Dontsova, T. A., Kuzminchuk, A. V., Yanushevska, O. I., Litynska, M.I., Kyrii, S.O. (2023). Membrane technologies: Ceramic membranes based on mineral raw materials: monograph, Kyiv: Igor Sikorsky Kyiv Polytechnic Institute, Polytechnic Publishing House.

International Organization for Standardization (2006). High quality ceramics (ceramics and technical ceramics of improved type). (DSTU ISO 14704:2006). Geneva, Switzerland: International Organization for Standardization.

International Organization for Standardization (2014). DSTU ISO 5017:2014 Fire-resistant, dense molded products. Method for determining apparent density, open porosity and total porosity. (DSTU ISO 5017:2014. ISO 5017:1998, IDT). Geneva, Switzerland: International Organization for Standardization.

Guesmi, Y., Ounifi, I., Khabbouchi, M., Agougui, H., Hafiane, A., Rodríguez, M. A. (2023). Cost-efficient natural apatite–metakaolin supported TiO2 mesoporous membrane for dye removal applications. Boletín de la Sociedad Española de Cerámica y Vidrio. https://doi.org/10.1016/j.bsecv.2023.10.002

Dongdong, W., Likun, H., Haiyang, S., Shaofang, L., Guangzhi, W., Rui, Z., Simin, Z., Xiyu, S. (2024). Enhanced photogenic self-cleaning of super hydrophilic Al2O3@GO-TiO2 ceramic membranes for efficient separation of oil-in-water emulsions. Chemical Engineering Journal, 486, 150211. https://doi.org/10.1016/j.cej.2024.150211

Ajenifuja, E., Ajao, J. А., Alayande, S. O., Bakare, M. K., Taleatu, Bidini A. E., Ajayi, O. B. (2016). Synthesis and characterization of pure and Ag-TiO2-modified diatomaceous aluminosilicate ceramic membranes for water remediation. Journal of Water Resource and Protection. 8(5). https://doi.org/10.4236/jwarp.2016.85049

Benkova, M., Soukup, O., Marek, J. (2020). Antimicrobial susceptibility testing: currently used methods and devices and the near future in clinical practice. Journal of Applied Microbiology, 129, 806–822. https://doi.org/10.1111/jam.14704

International Organization for Standardization (1999). Water quality. Enumeration of culturable micro-organisms – Colony count by inoculation in a nutrient agar culture medium, Geneva, Switzerland: International Organization for Standardization.

International Organization for Standardization (2016). Water quality – Determination of turbidity – Part 1: Quantitative methods, Geneva, Switzerland: International Organization for Standardization.

Dhanjai, A.S., Huimin, Z., Jiping, Ch., Samuel, M.M. (2019). Water Analysis | Determination of Chemical Oxygen Demand. Encyclopedia of Analytical Science (Third Edition). Academic Press. 258–270. https://doi.org/10.1016/B978-0-12-409547-2.14517-2

International Organization for Standardization (1989). Determination of the chemical oxygen demand (COD) in water samples by the photometric method Geneva, Switzerland: International Organization for Standardization.

Lopez de Dicastillo, C., Correa, M., Martínez, F., Streitt, C., Galotto, M. (2020). Antimicrobial Effect of Titanium Dioxide, Nanoparticles, 90891. https://doi.org/10.5772/intechopen.

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).