THE IMPACT OF ENZYME PREPARATIONS AND GROWTH ACTIVATORS ON YEAST IN THE TECHNOLOGY OF ALCOHOL FERMENTATION

DOI:

https://doi.org/10.15421/jchemtech.v32i2.299359Keywords:

enzyme preparations; corn; mash; dry matter; yeast; growth stimulators; fermentation; fermentation mashAbstract

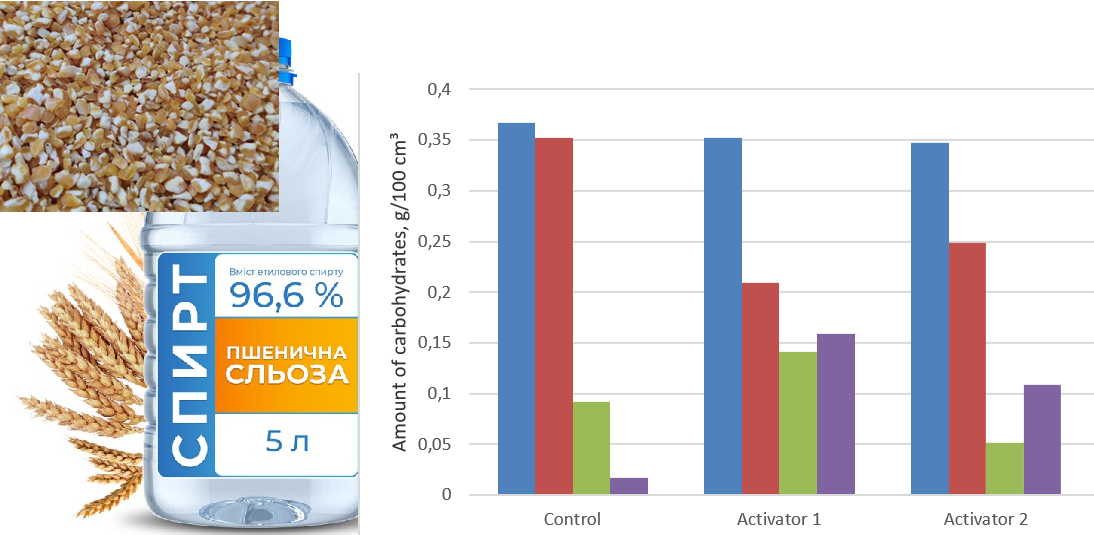

The article provides a characterization of enzyme preparations and growth activators used in the technologies of the alcohol industry. It is noted that industry losses are associated with market loss, shadow schemes, low implementation of innovative technologies, etc. With the privatization of the industry, entrepreneurs face tasks related to reducing material and energy losses. The influence of corn embryo containing substances that hinder starch hydrolysis and further fermentation into ethyl alcohol and the yield of the finished product has been investigated. The expediency of removing the corn embryo from the original grain in the technology of ethanol production. The potential of using high-concentration mash with enzyme preparations and dry yeast for fermentative hydrolysis with fermentation of mash of different concentrations is proven. The possibility of using dry yeast with a dry matter content in the mash of 24...28 % at a temperature of 30...35 °C is established. The effectiveness of alcohol and feed production using stillage is determined. The results of studies on the use of yeast growth stimulators at high concentrations of dry matter in mash are presented. The influence of enzyme preparations, dry alcohol yeast, and growth activators using corn as a raw material on technological indicators is determined. It is proven that the use of the proposed enzyme preparations with various yeast strains and growth activators increases profitability and alcohol yield, ensuring effective fermentation of high-concentration mash.

References

Babych, I., Boiko, P., Bondar, M., Kuts, A. (2022). Aspects of ethanol manufacture. Different purpose – different technological and economic solutions. Danish Scientific Journal, 60, 73–77.

Boiko, P. (2019). Technological and economic features of ethyl technical ethanol manufacture. Modern engineering and innovative technologies: International periodic scientific journal, 8(2), 39–42.

Bonassa, G., Schneider, L., Cremonez, P., de Jesus de Oliveira, C., Teleken, J. G., Frigo, E. P. (2015). Optimization of first generation alcoholic fermentation process with Saccharomyces cerevisiae. Acta Scientiarum: Technology, Brazil, 37(3), 313–320. https://doi.org/10.4025.

Ponnampalam, E., Steele, D.B., Burgdorf, D. (2004). Effect of Germ and Fiber Removal on Production of Ethanol from Corn. (February 2004). Applied Biochemistry and Biotechnology, 113-116(1-3), 837–842. doi: 10.1385/ABAB:115:1-3:0837.

Remize, F., Sablayrolles, J. M., Dequin, S. (2020). Re-assessment of the influence of yeast strain and environmental factors on glycerol production in wine. Journal of Applied Microbiology, 88, 371–378. doi: 10.1046/j.1365-2672.2000.00964.x

Zhao, J., Weiss, T., Du, Z., Hong, S., Bean, S. R., Li, Y., Wang, D. (2022). Comparative evaluation of physicochemical and fermentative responses of three sorghum varieties from dryland and irrigated land and the properties of proteins from distillers’ grains. Journal of Cereal Science, 104, 103432. https://doi.org/10.1016/j.jcs.2022.103432

Szambelan, K., Nowak, J., Szwengiel, A., Jelen, H. (2020). Quantitative and qualitative analysis of volatile compounds in sorghum distillates obtained under various hydrolysis and fermentation conditions. Industrial Crops and Products, 155, 112782. https://doi.org/10.1016/j.indcrop.2020.112782

Kovalchuk, S., Shiyan, P., Mudrak, T., Kuts, A., Kyrylenko, R. (2017). Investigation of the influence of nanoparticles of metals on fermentation of wort of high concentrations. Eureka: Life Sciences, 6, 51–56.

Kurakin, M. S., Ozherel’eva, A. V., Motyreva, O. G., Krapiva, T. V. (2021). [A new approach to the development of food products]. Food Processing: Techniques and Technology, 51(3), 434–448. (In Russian). doi: 10.21603/2074-9414-2021-3-434-448.

Deng, N., Du, H., Xu, Y. (2020). Cooperative response of Pichia kudriavzevii and Saccharomyces cerevisiae to lactic acid stress in baijiu fermentation. Journal of Agricultural and Food Chemistry, 68, 4903–4911. https://doi.org/10.1021/acs.jafc.9b08052

Panfilov, V. A. (2020). [Synergetic approach to agro-industrial technologies of the future]. Food Processing: Techniques and Technology, 50(4), 642-649. (In Russian). doi: 10.21603/2074-9414-2020-4-642-649.

Shiyan, P., Mudrak, T., Kyrylenko, R., Kovalchuk, S. (2017). Effect of nitrogen and mineral composition of the high-concentrated wort made from starch-containing raw materials on the cultivation of yeast. Eastern–European Journal of Enterprise Technologies, 11, 72–77.

Yu, W. W., Zhai, H. L., Xia, G. B., Tao, K. Y., Li, C., Yang, X. Q., Li, L. H. (2020). Starch fine molecular structures as a significant controller of the malting, mashing, and fermentation performance during beer production. Trends in Food Science & Technology, 105, 296–307. https://doi.org/10.1016/j.tifs.2020.09.010

Xu, X., Waters, D., Blanchard, C., Tan, S. H. (2021). A study on Australian sorghum grain fermentation performance and the changes in Zaopei major composition during solid-state fermentation. Journal of Cereal Science, 98, 103160. https://doi.org/10.1016/j.jcs.2021.103160

Babych, I. M., Boiko, P. M., Bondar, M. V. (2021). [Technological and economic aspects of ethyl alcohol production for various purposes]. Naukovi pratsi ONAKhT, 85(2), 77-83. (in Ukrainian).

Bulii, Yu. V., Obodovych, O. M. (2019). [Energy-efficient bioethanol technology]. Enerhiia. Biznes. Komfort, Odesa: ONAKhT, 13–14. (in Ukrainian).

Zakrevska, L. M. (2019). [Current trends and prospects for the development of enterprises of the alcohol industry of Ukraine]. Market infrastructure: electronic professional scientific and practical journal, 27, 142–146. (in Ukrainian).

Zakrevska, L. M. (2020). [Factors inhibiting the development of Ukrainian alcohol industry enterprises]. Rozvytok bukhhalterskoho obliku, opodatkuvannia i kontroliu v umovakh intehratsiinykh protsesiv, Kherson: DVNZ KhDAU, 262–263. (in Ukrainian).

(2018). [Collection of regulations and instructions on raw materials for ethyl alcohol producers], Kyiv; Vinnytsia: Nilan. (in Ukrainian).

Kovalchuk S.S. (2019). [Improving the technology of highly concentrated brews from grain raw materials] (D. Dissertation). (in Ukrainian). https://dspace.nuft.edu.ua/items/e24521dd-01ce-42a7-bcfc-0b6e9bef20cd

Kosminska, O. S. (2021). [Improving the technology of alcohol from starch-containing raw materials with intensification of the processes of preparation of matured mash at the conditions of the Uladovsk distillery]. (Master's dissertation). (in Ukrainian). https://dspace.nuft.edu.ua/server/api/core/bitstreams/a824a42a-75e8-4d41-9afc-ba2fddfca832/content

Mishchenko, O. S., Oliinyk, S. I. (2023). [Implementation of the national standard for ethyl alcohol]. Naukovi pratsi DNU «UkrNDIspyrtbioprod»: «Biotekhnolohii prodovolchykh produktiv: problemy i perspektyvy», 46–51. (in Ukrainian).

[News Service. Bioethanol industry of Ukraine. Assessment and prospects]. https://latifundist.com/analytics/30-bioetanol-stan-ta-otsinka-galuzi-v-ukrayini (in Ukrainian).

Ukrainets, A., Khomichak, L., Shyian, P., Oliinychuk, S. (2007). [Alcohol industry on the way to innovative development]. Kharchova i pererobna promyslovist, 12, 16–19. (in Ukrainian).

Shyian, P. L., Sosnytskyi, V. V., Oliinichuk, S. T. (2009). [Innovative technologies of the alcohol industry. Theory and practice: a monograph]. Kyiv: Askaniia. (in Ukrainian).

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).