STUDY OF MASS TRANSFER AND DIFFUSION PROCESSES OF SUCROSE INTO APPLE FRUIT PARTICLES

DOI:

https://doi.org/10.15421/jchemtech.v32i3.303315Keywords:

external diffusion; internal diffusion; mass feeder; candied fruit production; internal structure of the fruit; effective diffusion coefficient.Abstract

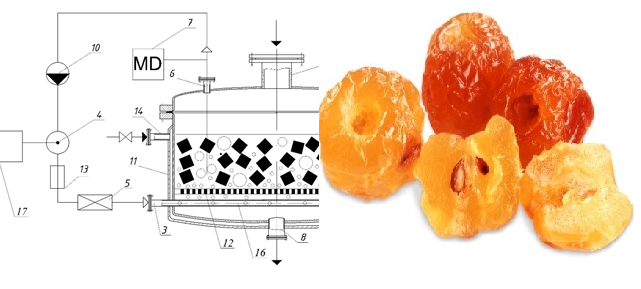

In this study, we designed a setup for blanching and saturating apple fruit particles with sucrose using a bubbling mode of sugar syrup with inert gas. For the saturation process, a sugar syrup was prepared at a temperature of 70 °C and a concentration of 60 % Brix. Based on photomicrographs of blanched fruit sections, we determined the average diameter and total length of channels between blanched apple cells to ascertain the particle's surface porosity, which was found to be 0.162 m2/m2. According to the established mechanism for the saturation process, we justified the physical essence of saturation processes in the external and internal diffusion regions. We demonstrated that irregular saturation exists in the external diffusion region at the beginning of the process and saturation occurs during the period of constant velocity. In the internal diffusion region, there is a period of decreasing saturation velocity. We proved that effective diffusion coefficients depend on both the hydrodynamic conditions of the process and the saturation region. In the external diffusion region, the coefficient of effective diffusion is 100–200 times larger than in the internal diffusion region. We proposed to generalize the saturation process separately for the external and internal diffusion regions. Based on the generalization of experimental data, we derived analytical dependencies of sucrose concentration change in apple fruit particles over time for the external and internal diffusion regions. These dependencies enable the theoretical calculation of the amount of sucrose transferring into apple fruit particles in the internal and external diffusion regions. Additionally, we derived dimensional equations in the article, which enable the calculation of the mass transfer coefficient for laminar, turbulent, and transitional regimes of bubbling syrup with inert gas. Using these dimensional equations, the amount of sucrose transferring from the syrup into apple fruit particles via mass transfer can be determined.

References

Deiana, M., Montoro, P., Jerković, I., Atzeri, A., Marijanović, Z., Serreli, G., Piacente, S., Ignazio, C., Tuberoso, G. (2019). First characterization of Pompia intrea candied fruit: The headspace chemical profile, polar extract composition and its biological activities. Food Research International, 120, 620–630. https://doi.org/10.1016/j.foodres.2018.11.016

Weijun, Ch., Yanyu, L., Bining, J. (2016). Dissipation behavior of five organophosphorus pesticides in kumquat sample during honeyed kumquat candied fruit processing. Food Control, 66, 87–92 https://doi.org/10.1016/j.foodcont.2016.01.033

Nunesa, C. Rato, A. E., Barros A. S., Saraiva J. A., Coimbra, M. A. (2009). Search for suitable maturation parameters to define the harvest maturity of plums (Prunus domestica L.): A case study of candied plums. Food Chemistry, 112(3), 570-574. https://doi.org/10.1016/j.foodchem.2008.06.007

A. Shukla, R.S. Shukla, C. Das, V. V. Goud. (2019). Gingerols infusion and multi-step process optimization for enhancement of color, sensory and functional profiles of candied mango. Food Chemistry, 300, 125195. https://doi.org/10.1016/j.foodchem.2019.125195

M. Aguirre-García, O. Cortés-Zavaleta, P. Hernández-Carranza, H. Ruiz-Espinosa, C. Enrique Ochoa-Velasco, I. Ruiz-López. (2023). Modeling the impregnation of roselle antioxidants into papaya cubes. Journal of Food Engineering, 357, 111585 https://doi.org/10.1016/j.jfoodeng.2023.111585

M. Aguirre-García, P. Hernández-Carranza, O. Cortés-Zavaleta, H. Ruiz-Espinosa, C.E. Ochoa-Velasco, I.I. Ruiz-López. (2020). Mass transfer analysis of bioactive compounds in apple wedges impregnated with beetroot juice: A 3D modelling approach. Journal of Food Engineering, 282, 110003. https://doi.org/10.1016/j.jfoodeng.2020.110003

Adsare, S. R., Bellary, A. N., Sowbhagya, H.B., Baskaran, R., Prakash, M., Rastogi, N. K. (2016). Osmotic treatment for the impregnation of anthocyanin in candies from Indian gooseberry (Emblica officinalis). Journal of Food Engineering, 175, 24–32. https://doi.org/10.1016/j.jfoodeng.2015.11.023

Aguirre-García, M., Cortés-Zavaleta, O., Ruiz-Espinosa, H., Ochoa-Velasco, C.E., Ruiz-López, I.I. (2022). The role of coupled water and solute diffusion and product shrinkage during osmotic dehydration. Journal of Food Engineering, 331, 111121. https://doi.org/10.1016/j.jfoodeng.2022.111121

Ramos-Morales, M., Aguirre-García, M., Cortés-Zavaleta, O., Ruiz-Espinosa, H., Estévez-Sánchez, K. H., Enrique, C., Ochoa-Velasco, C.E., Ruiz-López, I. I. (2024). Improving the bioactive content in honeydew melon by impregnation with Hibiscus extract/sucrose solutions: A coupled mass transfer analysis. Food and Bioproducts Processing, 144, 1–12. https://doi.org/10.1016/j.fbp.2023.12.001

Zecchi, B., Gerla P. (2020). Effective diffusion coefficients and mass flux ratio during osmotic dehydration considering real shape and shrinkage. Journal of Food Engineering, 274, 109821

Prithani, R., Dash, K. K. (2020). Mass transfer modelling in ultrasound assisted osmotic dehydration of kiwi fruit. Innovative Food Science & Emerging Technologies, 64, 102407 https://doi.org/10.1016/j.ifset.2020.102407

Abrahão, F. R., Corrêa, J. L. G. (2021). Osmotic dehydration: More than water loss and solid gain. Critical Reviews in Food Science and Nutrition, 63, 2970–2989. https://doi.org/10.1080/10408398.2021.1983764

Macedo, L. L., da Silva Araújo, C., Vimercati, W. C., Saraiva, S. H., Teixeira, L. J. Q. (2021). Influence of yacon syrup concentration and drying air temperature on properties of osmotically pre-dehydrated dried banana. Heat and Mass Transfer, 57(3), 441–451. https://doi.org/10.1007/s00231-020-02966-y

Huzova, I. O., Atamanyuk, V. M. (2022). Dynamics of drying processes of plant raw material in the period of decreasing speed. Journal of Chemistry and Technologies, 30(3), 419–430. https://doi.org/10.15421/jchemtech.v30i3.259694

Huzova, I.O., Atamanyuk, V.M. (2021). Mathematical interpretation of dynamics of temperature change during drying of hot monodisperse layer of organic raw materials. Journal of Chemistry and Technologies, 28(3), 278–288 https://doi.org/10.15421/082030

Huzova, I. (2020). Investigation of the energy-saving method during candied fruits filtration drying. Periodica Polytechnica Chemical Engineering, 64(4), 555–561. https://doi.org/10.3311/PPch.15107

Miletić, N., Popović, B., Mitrović, O., Kandić, M., Leposavić, A. (2014). Phenolic compounds and antioxidant capacity of dried and candied fruits commonly consumed in Serbia. Czech journal of food sciences, 32(4), 360–398. https://doi.org/10.17221/166/2013-CJFS

Sharma, A., Bachheti, A., Sharma, P., Bachheti, R. K., Husen, A. (2020). Phytochemistry, pharmacological activities, nanoparticle fabrication, commercial products and waste utilization of Carica papaya L.: A comprehensive review. Current research in biotechnology, 2, 145–160. https://doi.org/10.1016/j.crbiot.2020.11.001

Ahmed, M. Özcan, I.A., Uslu, M.M. (2024). The Effects of Microwave and Oven Drying on Bioactive Compounds Individual Phenolic Constituents and the Fatty Acid Profiles of Bitter Orange, Mandarin and Grapefruit Peel and Oils. Waste Biomass Valor, 15, 4735 – 4746

https://doi.org/10.1007/s12649-024-02488-2

Ashtiani, S. M., Aghkhani, M. H., Feizy, J., Martynenko, A. (2023). Effect of cold plasma pretreatment coupled with osmotic dehydration on drying kinetics and quality of mushroom (Agaricus bisporus). Food and Bioprocess Technology, 16, 2854–2876. https://doi.org/10.1007/s11947-023-03096-z

Contigiani, E. V., Jaramillo-Sánchez, G., Castro, M. A., Gómez, P. L., Alzamora, S. M. (2018). Postharvest quality of strawberry fruit (Fragaria x Ananassa Duch cv. Albion) as affected by ozone washing: Fungal spoilage, mechanical properties, and structure. Food and Bioprocess Technology, 11(9), 1639–1650. https://doi.org/10.1007/s11947-018-2127-0

Huzova, I., Atamanyuk, V. (2023). Study on the kinetics, hydrodynamics and mass transfer of the process of zucchini fruits saturation with sucrose from an aqueous solution. Food Science and Technology, 16(4), 56–63. https://doi.org/10.15673/fst.v16i4.2541

Huzova, I. (2023). Study on the diffusion process of zucchini fruits saturation with sucrose from an aqueous solution. Journal of Chemistry and Technologies, 31(3), 552–562. https://doi.org/10.15421/jchemtech.v31i3.280561

Atamanyuk, V., Huzova, I., Gnativ, Z. (2017). Study of diffusion processes in pumpkin particles during candied fruits production. Food Science and Technology, 11(4), 21–28.https://doi.org/10.15673/fst.v11i4.727

Fedoryshyn, O.M., Petrina, R.O., Krvavych, A.S., Hubrii, Z.V., Atamanyuk, V.M. (2023). Research on aspects of the extraction kinetics of metabolites of carlina acaulis while mixing. Voprosy Khimii i Khimicheskoi Tekhnologii, 1, 3–10. http://dx.doi.org/10.32434/0321-4095-2023-146-1-3-10

Gumnitsky, J., Venger, L., Sabadash, V., Hyvlud, A., Gnativ, Z. (2022). Physical And Mathematical Models Of Target Component Extraction From Rectlinear Capillaries. Chemistry and Chemical Technology, 16(1), 112–117. https://doi.org/10.23939/chcht16.01.112

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).