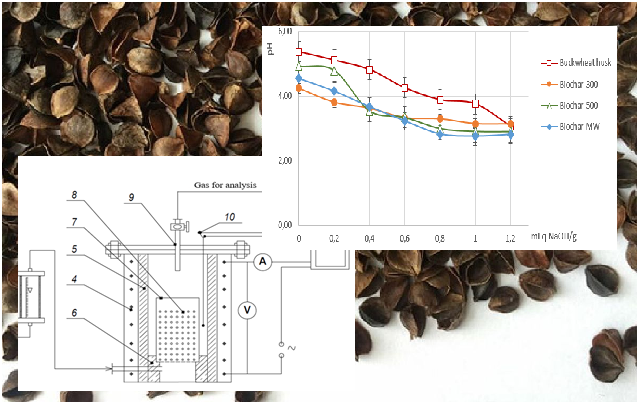

BUCKWHEAT HUSK BIOCHAR: PREPARATION AND STUDY OF ACID-BASE AND ION-EXCHANGE PROPERTIES

DOI:

https://doi.org/10.15421/jchemtech.v32i3.306261Keywords:

buckwheat husk, biochar, pyrolysis, microwave irradiation, thermochemical conversion, acid-base properties, ion exchange propertiesAbstract

Ukraine is one of the world's leading producers of buckwheat grain, so it is very important to address the issue of including its processing waste in the production cycle. Buckwheat husk is a promising raw material for biochar production. The aim of the study is to obtain biochar as an additive during food waste composting and to characterise its acid-base and ion-exchange properties. The nature of the potentiometric titration curves of biochar is determined by the additive contribution of all ionised groups of biochar and allows us to classify the studied products as ion exchangers of polyfunctional type. It has been shown that, possessing the properties of ampholytes, biochars in the composting process not only act as acceptors of metal ions, but also function as a soft regulator of pH. The number of groups with the ability to exchange anions ranges from 0.1 (biochar-500) to 1.2 (biochar-MX). The groups with the highest pKa values in the range of biochars studied were found in biochar-500 (pK 7.5), biochar-MX (pK - 7.3) and biochar-300 (pKb 7.0). Other anion-exchange groups have pKb from 4.9 to 6.3 meq/g, which characterises them as weakly basic.

References

Kwon, S. J., Roy, S. K., Choi, J., Park, J., Cho, S., Sarker, K., Woo, S. H. (2018). Recent research updates on functional components in Buckwheat. Journal of Agricultural Science Chungbuk National University, 34(1), 1–8.

Food and Agriculture Organization https://www.fao.org/faostat/

Huda, M. N., Lu, S., Jahan, T., Ding, M., Jha, R., Zhang, K., Zhang, W., Georgiev, M. I., Park, S. U., Zhou, M. (2021). Treasure from garden: Bioactive compounds of buckwheat. Food Chemistry, 335, 127653. https://doi.org/10.1016/j.foodchem.2020.127653

Zhu, F. (2016). Chemical composition and health effects of Tartary buckwheat. Food Chemistry, 203, 231–245. https://doi.org/10.1016/j.foodchem.2016.02.050

Gonçalves, M., Salvador, R., Francisco, A., Piekarski, C. (2023). Value recovery from waste in the processing of buckwheat: Opportunities for a circular bioeconomy. Engineering Reports, e12757. https://doi.org/10.1002/eng2.12757

Jeyasubramanian, K., Baskaran, T., Arumugam, S., Raja, D., Seenivasan, S., Vallinayagam, P., Madhavan, D., Sundaramoorthy, M., Boobalan, R. (2021). A complete review on biochar: Production, property, multifaceted applications, interaction mechanism and computational approach. Fuel. 292. 120243. https://doi.org/10.1016/j.fuel.2021.120243

Allohverdi, T., Mohanty, A. K., Roy, P., Misra, M. (2021). A Review on Current Status of Biochar Uses in Agriculture. Molecules, 26(18), 5584. https://doi.org/10.3390/molecules26185584

Liu, P., Ptacek, C., Blowes, D., Finfrock, Y., Liu, Y. (2019). Characterization of chromium species and distribution during Cr (VI) removal by biochar using confocal micro-X-ray fluorescence redox mapping and X-ray absorption spectroscopy. Environment international, 134, 105216. https://doi.org/10.1016/j.envint.2019.105216

Tang, J., Lv, H., Gong, Y., Huang, Y. (2015). Preparation and characterization of a novel graphene/biochar composite for aqueous phenanthrene and mercury removal. Bioresource Technology, 196, 355–363. https://doi.org/10.1016/j.biortech.2015.07.047

Wan, S., Qiu, L., Li, Y., Sun, J., Gao, B., He, F., Wan, W. (2020). Accelerated antimony and copper removal by manganese oxide embedded in biochar with enlarged pore structure. Chemical Engineering Journal, 126021. https://doi.org/10.1016/j.cej.2020.126021

Wang, Y., Zhang, Z., Zhang, S., Wang, Y., Hu, S., Xiang, J., Hu, X. (2020). Steam reforming of acetic acid over Ni/biochar catalyst treated with HNO3: Impacts of the treatment on surface properties and catalytic behaviors. Fuel, 278, 118341. https://doi.org/10.1016/j.fuel.2020.118341

Zhang, H., Yue, X., Li, F., Xiao, R., Zhang, Y., Gu, D. (2018). Preparation of rice straw-derived biochar for efficient cadmium removal by modification of oxygen-containing functional groups. Science of the Total Environment, 631, 795–802. https://doi.org/10.1016/j.scitotenv.2018.03.071

Shang, X., Wu, S., Liu, Y., Zhang, K., Guo, M., Zhou, Y., Zhu, J., Li, X., Miao, R. (2024). Rice husk and its derived biochar assist phytoremediation of heavy metals and PAHs co-contaminated soils but differently affect bacterial community. Journal of Hazardous Materials, 466. 133684. https://doi.org/10.1016/j.jhazmat.2024.133684

Adekiya, A. O., Adebiyi, O. V., Ibaba, A. L., Aremu, C., Ajibade, R. O. (2022). Effects of wood biochar and potassium fertilizer on soil properties, growth and yield of sweet potato (Ipomea batata). Heliyon, 8(11), e11728. https://doi.org/10.1016/j.heliyon.2022.e11728

Liu, S., Xu, W., Liu, Y., Tan, X., Zeng, G., Li, X., Liang, J., Zhou, Z., Yan, Z., Cai, X. (2017). Facile synthesis of Cu (II) impregnated biochar with enhanced adsorption activity for the removal of doxycycline hydrochloride from water. Science of The Total Environment. 592. https://doi.org/10.1016/j.scitotenv.2017.03.087

Sari, R. M., Gea, S., Wirjosentono, B., Hendrana, S., Hutapea, Y. A. (2020). Improving Quality and Yield Production of Coconut Shell Charcoal Through a Modified Pyrolysis Reactor with Tar Scrubber to Reduce Smoke Pollution. Polish Journal of Environmental Studies, 29(2), 1815–1824. https://doi.org/10.15244/pjoes/110582

Manyuchi, M., Mbohwa, C., Muzenda, E. (2019). Evaluating the Usability of Bio Coal from Sugar Cane Bagasse as a Solid Fuel. Procedia Manufacturing, 33, 516–521. https://doi.org/10.1016/j.promfg.2019.04.064

Sedmihradská, A., Pohořelý, M., Jevič, P., Skoblia, S., Beňo, Z., Farták, J., Čech, B., Hartman, M. (2020). Pyrolysis of wheat and barley straw. Research in Agricultural Engineering, 66(1), 8–17. https://doi.org/10.17221/26/2019-RAE

Barbanera, M., Funcia, I. (2019). Effect of the temperature on the spent coffee grounds torrefaction process in a continuous pilot-scale reactor. Fuel., 262. 116493. https://doi.org/10.1016/j.fuel.2019.116493

Sahoo, S., Vijay, V. K., Chandra, R., Kumar, H. (2021). Production and characterization of biochar produced from slow pyrolysis of pigeon pea stalk and bamboo. Cleaner Engineering and Technology, 3, 100101. https://doi.org/10.1016/j.clet.2021.100101

Cantrell, K., Hunt, P. G., Uchimiya, M., Novak, J., Ro, K. (2012). Impact of Pyrolysis Temperature and Manure Source on Physicochemical Characteristics of Biochar. Bioresource technology, 107, 419–428. https://doi.org/10.1016/j.biortech.2011.11.084

Klinghoffer, N., Castaldi, M., Nzihou, A. (2015). Influence of char composition and inorganics on catalytic activity of char from biomass gasification, Fuel, 157. https://doi.org/10.1016/j.fuel.2015.04.036

Kan, T., Strezov, V., Evans, T. (2015). Lignocellulosic Biomass Pyrolysis: A Review of Product Properties and Effects of Pyrolysis Parameters. Renewable and Sustainable Energy Reviews, 57. https://doi.org/10.1016/j.rser.2015.12.185

Joshi, S., Ramola, S., Singh, B., Anerao, P., Singh, L. (2022). Waste to Wealth: Types of Raw Materials for Preparation of Biochar and Their Characteristics. In Engineered Biochar, 21–33. https://doi.org/10.1007/978-981-19- 2488-0_2

Li, H., Dong, X., da Silva, E., De Oliveira, L., Chen, Y. (2017). Mechanisms of metal sorption by biochars: Biochar characteristics and modifications. Chemosphere, 178, 466–478. https://doi.org/10.1016/j.chemosphere.2017.03.072

Ramola, S., Belwal, T., Li, C., Liu, Y., Wang, Y., Yang, S., Zhou, C. (2021). Preparation and application of novel rice husk biochar–calcite composites for phosphate removal from aqueous medium. Journal of Cleaner Production, 299, 126802. https://doi.org/10.1016/j.jclepro.2021.126802

Ebrahimzadeh Omran, S., Shorafa, M., Zolfaghari, A., Toolarood, A. (2020). The effect of biochar on severity of soil water repellency of crude oil-contaminated soil. Environmental Science and Pollution Research, 27, 6022–6032. https://doi.org/10.1007/s11356-019-07246-9

Zhou, X., Zhou, J., Liu, Y., Guo, J., Jialin, R., Zhou, F. (2018). Preparation of iminodiacetic acid-modified magnetic biochar by carbonization, magnetization and functional modification for Cd(II) removal in water. Fuel, 233, 469–479. https://doi.org/10.1016/j.fuel.2018.06.075

Dziedzic, K., Górecka, D., Kucharska, M., Przybylska, B. (2012). Influence of technological process during buckwheat groats production on dietary fibre content and sorption of bile acids. Food Research International, 47(2). 279–283. https://doi.org/10.1016/j.foodres.2011.07.020

Song, C, Ma, C, Xiang, D. (2019). Variations in Accumulation of Lignin and Cellulose and Metabolic Changes in Seed Hull Provide Insight into Dehulling Characteristic of Tartary Buckwheat Seeds. International Journal of Molecular Sciences, 20(3), 524. https://doi.org/10.3390/ijms20030524

Godlewska, P., Schmidt, H. P., Ok, Y. S., Oleszczuk, P. (2017). Biochar for composting improvement and contaminants reduction. A review. Bioresource Technology, 246, 193–202. https://doi.org/10.1016/j.biortech.2017.07.095

Qasim, W., Lee, M., Moon, B., Okyere, F., Khan, F., Mohammad, N., Kim, H. (2018). Composting of chicken manure with a mixture of sawdust and wood shavings under forced aeration in a closed reactor system. International Journal of Recycling of Organic Waste in Agriculture. 7(5). 261-267. https://doi.org/10.1007/s40093-018-0212-z

Yu, Y., Yang, B., Petropoulos, E., Duan, J., Yang, L., Xue, L. (2022). The Potential of Biochar as N Carrier to Recover N from Wastewater for Reuse in Planting Soil: Adsorption Capacity and Bioavailability Analysis. Separations, 9(11), 337. https://doi.org/10.3390/separations9110337

Samal, K., Dash, R., Bhunia, P. (2017). Treatment of wastewater by vermifiltration integrated with macrophyte filter: A review. Journal of Environmental Chemical Engineering, 5(3), 2274–2289. https://doi.org/10.1016/j.jece.2017.04.026

Sánchez-García, M., Alburquerque, J., Sánchez-Monedero, M., Roig, A., Cayuela, M. L. (2015). Biochar accelerates organic matter degradation and enhances N mineralisation during composting of poultry manure without a relevant impact on gas emissions. Bioresource Technology, 192, 272–279. https://doi.org/10.1016/j.biortech.2015.05.003

Li, R., Wang, Q., Zhang, Z., Zhang, G., Li, Z., Wang, L., Zheng, J. (2014). Nutrient transformation during aerobic composting of pig manure with biochar prepared at different temperatures. Environmental Technology, 36(7), 815–826. https://doi.org/10.1080/09593330.2014.963692

Aoac, C. (2005). Official methods of analysis of the Association of Analytical Chemists International. Official Methods: Gaithersburg, MD, USA.

Jara, P., Schoeninger, V., Dias, L., Siqueira, V., Lourente, E. (2022). Physicochemical quality characteristics of buckwheat flour. Engenharia Agrícola. 42(4). https://doi.org/10.1590/1809-4430-Eng.Agric.v42n4e20210026/2022

Wang, F., Du, C., Chen, J., Shi, L., Li, H. (2021). A New Method for Determination of Pectin Content Using Spectrophotometry. Polymers, 13(17), 2847. https://doi.org/10.3390/polym13172847

Krusir, G., Sagdeeva, O., Malovanyy, M., Shunko, H., Gnizdovskyi, O. (2020). Investigation of Enzymatic Degradation of Solid Winemaking Wastes. Journal of Ecological Engineering, 21(2), 72–79. https://doi.org/10.12911/22998993/116345

Pillsbury, D. M., Kulchar, G. V. (1934). The use of the Hagedorn-Jensen method in the determination of skin glucose. Journal of Biological Chemistry, 106(1), 351–356. https://doi.org/10.1016/S0021-9258(18)75485-9

Ioelovich, M. (2022). Features of water vapor sorption by cellulose materials. World Journal of Advanced Research and Reviews. 13(03), 254–263. https://doi.org/10.30574/wjarr.2022.13.3.0233

Elsabawy, K.M., Fallatah, A.M., Owidah, Z.O. (2024). Chapter 7 - A new advanced approach of ultrafast synthesis of ultrahigh Brunauer–Emmett–Teller surface area crystalline/noncrystalline porous coordinated polymers. Porous Coordination Polymers From Fundamentals to Advanced Applications 2024, 177–205. https://doi.org/10.1016/B978-0-323-95535-5.00007-9

Cherno, N. K., Krusir, G. V. (1992). Acid-base and ion-exchange properties of dietary fibers. Applied Biochemistry and Microbiology. 28(2), 297–303.

Cherno, N.K., Krusir, G. V., Kovalenko, O.V. (2010). [Biocorrectors of digestive processes: monograph]. Odesa: ONAFT. (in Ukrainian).

Sharma, A., Pareek, V., Zhang, D. (2015). Biomass Pyrolysis – A Review of Modelling, Process Parameters and Catalytic Studies. Renewable and Sustainable Energy Reviews, 50(9), 1081–1096. https://doi.org/10.1016/j.rser.2015.04.193

Cha, J., Park, S., Jung, S. C., Ryu, C., Jeon, J. K., Shin, M. C., Park, Y. K. (2016). Production and Utilization of Biochar: A Review. Journal of Industrial and Engineering Chemistry, 40, 1–15. https://doi.org/10.1016/j.jiec.2016.06.002

Yaashikaa, P. R., Kumar, P., Varjani, S., Anbalagan, S. (2019). Advances in production and application of biochar from lignocellulosic feedstocks for remediation of environmental pollutants, Bioresource Technology. 292, 122030. https://doi.org/10.1016/j.biortech.2019.122030

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).