IMPROVEMENT OF THE THERMODYNAMIC CYCLE OF STEAM TURBINE INSTALLATIONS OF THERMAL POWER PLANTS

DOI:

https://doi.org/10.15421/jchemtech.v32i2.307446Keywords:

basic thermodynamic cycle of steam turbine plants, heat input, heat output, expansion work, thermal efficiency, modified plantAbstract

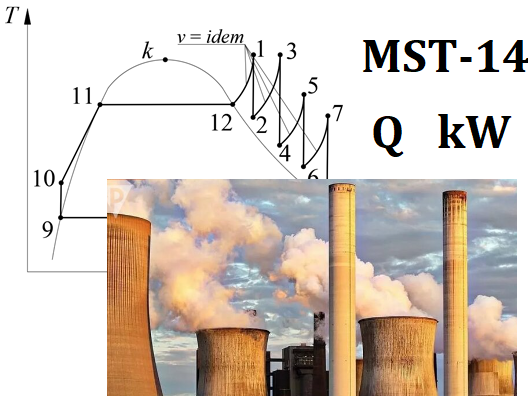

The production of electricity due to the heat of combustion of fuel is carried out mainly with the help of steam turbine plants (STP) that work according to the thermodynamic Rankine cycle. In the traditional Rankine cycle, steam formation and superheating of steam is carried out in an isobaric process, which loses to an isochoric process because part of the heat that is supplied isobarically is spent on premature expansion of the working body outside the turbine. It is proposed to improve the Rankine thermodynamic cycle by leaving the isobaric process of saturated steam formation, and also to carry out boiler and intermediate steam overheating in isochoric processes. As a basic thermodynamic cycle for comparison, the cycle of the MST-14 type ship steam turbine plant with a capacity of 16,200 kW was adopted. A comparison of the efficiency indicators of the proposed thermodynamic cycle and the cycle of the basic plant indicates the significant advantages of the proposed cycle, which allows increasing the power of the plant to 29,000 kW, other things being equal. The proposed improvement of the Rankine cycle will complicate the design of the steam turbine plant and increase the cost of their manufacture, but these costs will be compensate by a reduction in fuel consumption and carbon dioxide emissions.

References

Horbov, V.M., Kot, V.P. (2013). Encyclopedia of ship power. NUK. https://uk.wikipedia.org/wiki/Teplovi_elektrostancii_Ukraine

Kirillin, V.O., Sychev, V.V., Sheindlyn, A. Ye. (1983). Technical Тermodynamics. M.

Kravchenko, M.B. (2021). Whirlwinds on Earth and in Space. Odessa publishing house and printing house «Astroprint».

Lavrenchenko, G. K., Slinko, A. G., Boychuk, A. S., Halkin, V. M., Kozlovskyi, S. V. (2023). Improved thermodynamic cycle of a steam turbine plant. Journal of Chemistry and Technologies, 31(1), 178–185. https://doi.org/10.15421/jchemtech.v31i1.274768

Lavrenchenko, G. K., Slynko, O. G., Galkin, V. M., Kozlovskyi, S. V., Boychuk, A. S. (2022). Hydrodynamic method of converting liquid into superheated steam. Refrigeration Engineering and Technology, 58(2), 92–97. https://doi.org/10.15673/ret.v58i2.2381

Lavrenchenko, G. K., Slynko, O. G., Boychuk, A. S., Kozlovskyi, S. V., Galkin, V. M. (2023). Conversion of liquid to steam. how and why? Journal of Chemistry and Technologies, 31(3), 678–684. https://doi.org/10.15421/jchemtech.v31i3.285771

Axelband, A. M. (1970). Ship power plants. Shipbuilding, L.

Lemmon, E.W., Huber, M.L., McLinden, M.O. (2007). NIST Reference Fluid Thermodynamic and Transport Properties. REFPROP, Version 8.0. Gaithersburg.

Lavrenchenko, G.K., Slynko, O.G., Galkin, V.M., Kozlovskyi, S.V., Boychuk, A.S. (2022). Utilization combined energy refrigeration unit with full regenerative heat exchange. Refrigeration Engineering and Technology, 58(1), 50-61. https://doi.org/10.15673/ret.v58i1.2315

Qu, J., Feng, Y., Zhu, Y., Zhou, S., Zhang, W. (2021). Design and thermodynamic analysis of a combined system including steam Rankine cycle, organic Rankine cycle, and power turbine for marine low-speed diesel engine waste heat recovery. Energy Conversion and Management, 245, 114580 https://doi.org/10.1016/j.enconman.2021.114580

Tanuma, T. (2022). Advances in Steam Turbines for Modern Power Plants. Woodhead Publishing Series in Energy. https://doi.org/10.1016/C2020-0-01671-3

Koroglu, T., Sogut, O. S. (2018). Conventional and advanced exergy analyses of a marine steam power plant. Energy, 163, 392–403. https://doi.org/10.1016/j.energy.2018.08.119

Koroglu, T., Sogut, O.S. (2018). Conventional and advanced exergy analyses of a marine steam power plant. Energy, Volume 163, 392–403.

https://doi.org/10.1016/j.energy.2018.08.119

Konur, O., Yuksel, O., Korkmaz, S.A., C. Colpan, O., Saatcioglu, O.Y., Muslu, I. (2022). Thermal design and analysis of an organic rankine cycle system utilizing the main engine and cargo oil pump turbine based waste heats in a large tanker ship. Journal of Cleaner Production, 368, 133230. https://doi.org/10.1016/j.jclepro.2022.133230

Dotto, A., Sacchi, R., Satta, F., Campora, U. (2023). Dynamic performance simulation of combined gas electric and steam power plants for cruise-ferry ships. Next Energy, 1(3), 100020. https://doi.org/10.1016/j.nxener.2023.100020

Houm, Sh., Zhou, Ya., Yu, L., Zhang, F., Cao, Sh., Wu, Yu. (2018). Optimization of a novel cogeneration system including a gas turbine, a supercritical CO2 recompression cycle, a steam power cycle and an organic Rankine cycle. Energy Conversion and Management, 172, 457–471. https://doi.org/10.1016/j.enconman.2018.07.042

Park, S-Ch., Son, Ch.-H., Lee, H.-S., Lim, S.-T., Yoon, J.-W., Choi, M.-K., Seol, S.-H. (2023). Performance analysis of an organic Rankine cycle with an internal heat exchanger considering turbine pressure ratio and efficiency. Energy, 285, 129507. https://doi.org/10.1016/j.energy.2023.129507

Porto-Hernandez, L.A., Vargas, J.V.C., Munoz, M.N., Galeano-Cabral, J., Ordonez, J.C., Balmant, W., Mariano, A.B. (2023). Energy Conversion and Management, 289, 117148. https://doi.org/10.1016/j.enconman.2023.117148

Reshaeel, M., Javed, A., Jamil, J., Ali, M., Mahmood, M., Waqas, A. (2022). Multiparametric optimization of a reheated organic Rankine cycle for waste heat recovery based repowering of a degraded combined cycle gas turbine power plant. Energy Conversion and Management, 254, 115237. https://doi.org/10.1016/j.enconman.2022.115237

Yuan, H., Zhao, J., Li, Y., Zhang, J., Mei, N. (2017). Energy analysis of a subsea steam Rankine cycle for the subsea power supply. Energy Procedia, 136, 444–449. https://doi.org/10.1016/j.egypro.2017.10.301

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).