QUANTUM-MECHANICAL METHODOLOGY FOR DETERMINING THE TEMPERATURE DEPENDENCE OF CONTACT ANGLE IN MELT–SOLID METAL SYSTEMS

DOI:

https://doi.org/10.15421/jchemtech.v32i3.307707Keywords:

wetting angle, temperature, density functional theory, binding energy, liquid tin drop, steel substrate.Abstract

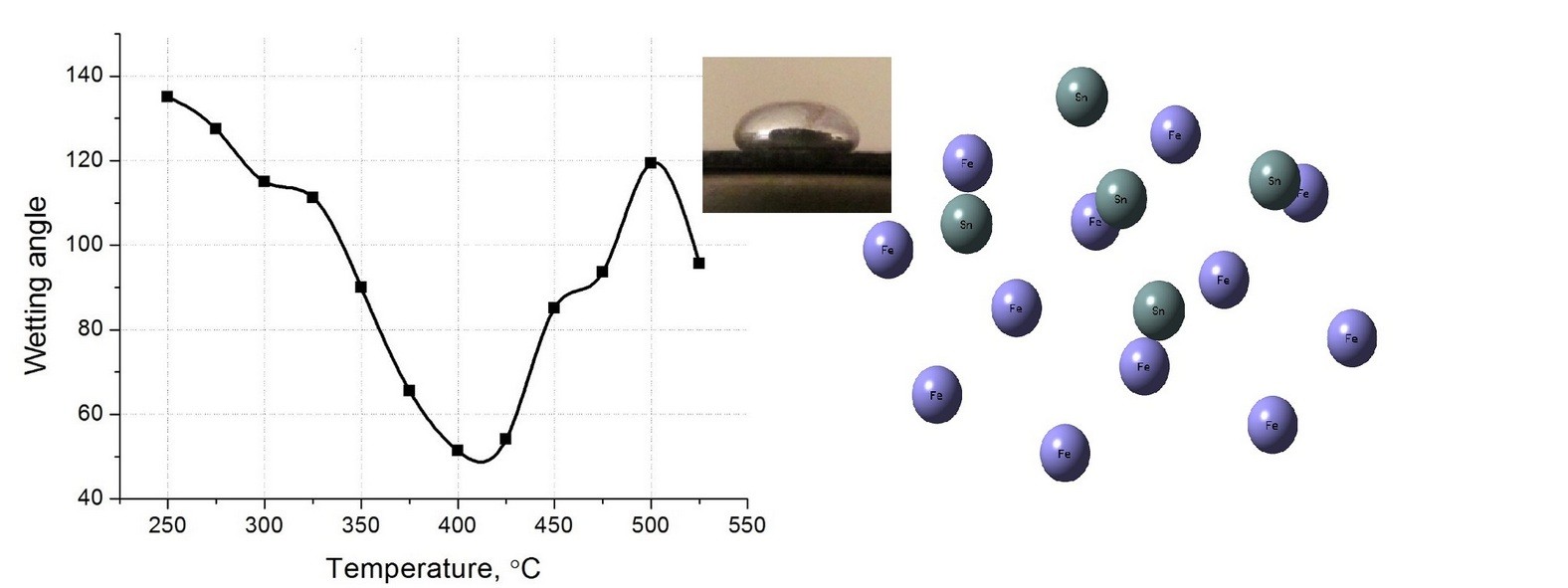

Aim. In order to determine the composite materials’ manufacturing process parameters, it is necessary to evaluate the stability of their structural components and determine the contact angle of wetting of the filler with the molten binder at the infiltration temperature. The development of a theoretical method for determining the dependence of the contact angle of wetting on temperature in melt – solid metal systems makes it possible to reduce the volume of experimental studies. Methods. The paper presents a quantum mechanical methodology for calculating the binding energy of interacting substances, as well as an experimental study of the dependence of the contact angle on temperature for tin – steel systems. The methodology is based on the calculation of the binding energy between atoms of interacting substances using density functional theory. Results. The calculations show an anomalous behavior of contact angle values for the tin–steel system with increasing temperatures. It means that, when the temperature increases, the values of the contact angle initially become lower, and later, in the temperature range of 450-510 °C, an increase in the contact angle is observed. The obtained theoretical and experimental data correlate well with each other. Conclusions. The appearance of extreme regions in the experimental and theoretical temperature dependences is associated with the thermal expansion of interatomic distances in the crystal lattice. The obtained theoretical and experimental data correlate well with each other and base on the thermal expansion of interatomic distances in the crystal lattice.

References

Georgantzinos, S. K., Giannopoulos, G. I., Stamoulis, K., Markolefas, S. (2023). Composites in Aerospace and Mechanical Engineering. Materials, 16(22), 7230–7243. https://doi.org/10.3390/ma16227230

Ganesh, V., Leich, L., Dorow-Gerpach, D., Heuer, S., Coenen, J. W., Wirtz, M., Pintsuk, G., Gormann, F., Lied, Ph., Baumgärtner, S., Theisen, W., Linsmeier, Ch. (2022). Manufacturing of W/steel composites using electro-discharge sintering process. Nucl. Mater. Energy, 30, 101089. https://doi.org/10.1016/j.nme.2021.101089

Geni, M., Kikuchi, M. (1998). Damage Analysis of Aluminum Matrix Composite Considering Non-Uniform Distribution of SiC Particles. Acta Mater., 46(9), 3125–3133. https://doi.org/10.1016/S1359-6454(98)00004-4

Oghbaei, M., Mirzaee, O. (2010). Microwave versus conventional sintering: A review of fundamentals, advantages and applications. J. Alloys Compd., 494(1-2), 175–189. https://doi.org/10.1016/j.jallcom.2010.01.068

Chintada, S., Dora, S. P., Kare, D., Doddi, P. R. V. (2021). Developments in sintered aluminum-based composites. Met. Powder Rep., 76(6), 32–39. https://doi.org/10.1016/S0026-0657(21)00301-5

Guillon, O., Rheinheimer, W., Bram, M. (2023). A Perspective on Emerging and Future Sintering Technologies of Ceramic. Materials Adv. Eng. Mater., 25: 2201870. https://doi.org/10.1002/adem.202201870

Liu, J., Silveira, J., Groarke, R., Parab, S., Singh, H., McCarthy, E., Karazi, S., Mussatto, A., Houghtaling, J., Ahad, I. U., Naher, S., Brabazon D. (2019). Effect of powder metallurgy synthesis parameters for pure aluminium on resultant mechanical properties. Int. J. Mater. Form., 12(1), 79–87. https://doi.org/10.1007/s12289-018-1408-5

Edosa, O. O., Tekweme, F. K., Gupta, K. (2022). A review on the influence of process parameters on powder metallurgy parts. Eng. Appl. Sci. Res., 49(3), 433–443. https://www.tci-thaijo.org/index.php/easr/index

Sukhova, O. V., Syrovatko, Yu. V. (2018). Contact interaction at the composites interfaces between the microcrystalline particulate and the molten matrix. Journal of Physics and Electronics, 26(2), 29–32. https://doi.org/10.15421/331819

Nardin, M., Schultz, J. (1993). Interactions and Properties of Composites: b) Adhesion-Composites Properties Relationships. In: Akovali, G. (eds.), The Interfacial Interactions in Polymeric Composites. NATO ASI Series, Springer, Dordrecht. https://doi.org/10.1007/978-94-011-1642-8_5

Sharan Chandran, M., Padmanabhan, K. (2019). Microbond fibre bundle pullout technique to evaluate the interfacial adhesion of polyethylene and polypropylene self reinforced composites. Appl. Adhes. Sci., 7, 5. https://doi.org/10.1186/s40563-019-0121-z

De Coninck, J. (2022). An Introduction to Wettability and Wetting Phenomena. In: Marengo, M., De Coninck, J. (eds.), The Surface Wettability Effect on Phase Change. Springer, Cham. https://doi.org/10.1007/978-3-030-82992-6_2

Kambolov, D. A., Kashezhev, A. Z., Kutuev, R. A., Korotkov, P. K., Manukyants, A. R., Ponezhev, M. Kh., Sozaev, V. A. (2015). On the wetting of aluminum and copper surface by tin-lead melts. J. Surf. Investig., 9, 636–640. https://doi.org/10.1134/S1027451015020305

Dalakova, N. V., Elekoeva, K. M., Kashezhev, A. Z., Manukyants, A. R., Prokhorenko, A. D., Ponezhev, M. Kh., Sozaev, V. A. (2014). Polytherms of angles of aluminum and aluminum-lithium alloy wetting by tin-based melts. J. Surf. Investig., 8, 360–363. https://doi.org/10.1134/S1027451014020347

Lößlein, S. M., Mücklich, F., Grützmacher, Ph. G. (2022). Topography versus chemistry – How can we control surface wetting?, J. Colloid Interface Sci., 609, 645–656. https://doi.org/10.1016/j.jcis.2021.11.071.

Wu, D., Wang, P., Wu, P., Yang, Q., Liu, F., Han, Y., Xu, F., Wang, L. (2015). Determination of contact angle of droplet on convex and concave spherical surfaces. Chem. Phys., 457, 63–69. https://doi.org/10.1016/j.chemphys.2015.05.020

Chesters, A. K. (1977). An analytical solution for the profile and volume of a small drop or bubble symmetrical about a vertical axis. J. Fluid Mech., 81, 609–626. https://doi.org/10.1017/S0022112077002250

Shanahan, M. E. R. (1982). An approximate theory describing the profile of a sessile drop. J. Chem. Soc., Faraday Trans. 1, 78, 2701–2710. https://doi.org/10.1039/F19827802701

Shanahan, M. E. R. (1984). Profile and contact angle of small sessile drops. A more general approximate solution. J. Chem. Soc., Faraday Trans. I, 80, 37–45. https://doi.org/10.1039/F19848000037

Hejda, F., Solar, P., Kousal, J. (2010). Surface Free Energy Determination by Contact Angle Measurements: A Comparison of Various Approaches. In WDS'10 Proceedings of Contributed Papers, Part III – Physics, 25–30.

Koch, W., Holthausen, M. C. (2001). Chemists Guide to Density Functional Theory. 2nd edn. Wiley, New York.

Kohn, W., Sham, L. J. (1965). Self-Consistent Equations Including Exchange and Correlation Effects. Phys. Rev., 140(4A), A1133 https://doi.org/10.1103/PhysRev.140.A1133

Burke, K. (2012). Perspective on density functional theory. J. Chem. Phys., 136(15), 150901. https://doi.org/10.1063/1.4704546

Miehlich, B., Savin, A., Stoll, H., Preuss, H. (1989). Results obtained with the correlation energy density functionals of becke and Lee, Yang and Parr. Chem. Phys. Lett., 157(3), 200–206. https://doi.org/10.1016/0009-2614(89)87234-3

Keire, D. A., Jang, Y. H., Li, L., Dasgupta, S., Goddard, W. A., Shively, J. E. (2001). Chelators for radioimmunotherapy: I. NMR and ab initio calculation studies on 1,4,7,10-tetra(carboxyethyl)-1,4,7,10-tetraazacyclododecane (DO4Pr) and 1,4,7-tris(carboxymethyl)-10-(carboxyethyl)-1,4,7,10-tetraazacyclododecane (DO3A1Pr). Inorg. Chem., 40(17), 4310–4318. https://doi.org/10.1021/ic0010297

Shtapenko, Е. Ph., Zabludovsky, V. О., Tytarenko, V. V. (2015). The Development of the Atomic Theory of the Formation of a New Phase in Adsorbing Layers in an External Electric Field. Physics and Chemistry of Solid State, 16(3), 520–523. https://doi.org/10.15330/pcss.16.3.520-523

Shtapenko, E. F., Tytarenko, V. V., Zabludovsky, V. A., Voronkov, E. O. (2020). Quantum Mechanical Approach for Determining the Activation Energy of Surface Diffusion. Phys. Solid State, 62, 2191–2196. https://doi.org/10.1134/S1063783420110311

Shtapenko, E. F., Zabludovsky, V. A., Tytarenko, V. V. (2018). Diffusion at the Film–Substrate Interface during Nickel Electrocrystallization on a Copper Substrate. J. Surf. Investig., 12, 377–382. https://doi.org/10.1134/S1027451018020362

Tytarenko, V. V., Shtapenko, E. Ph., Voronkov, E. О., Zabludovsky, V. A., Kolodziejczyk, W., Kapusta, K., Kuznetsov, V. N. (2021). Quantum-Mechanical Modeling of the Interaction between Carbon Nanostructures and Metal Ions. J. Surf. Investig., 15, 866–871. https://doi.org/10.1134/S102745102104039X

Tytarenko, V. V., Shtapenko, E. Ph., Voronkov, E. O., Vangara, A., Zabludovsky, V. A., Kolodziejczyk, W., Kapusta, K., Okovytyy, S. I. (2021). Adsorption of Co, Ni, Cu, Zn Metal Ions on Fullerene C60 and on Single-Wall Carbon Nanotubes C48 as a Driven Force of Composite Coatings’ Electrodeposition. J. Chem. Technol., 29(1), 42–54. https://doi.org/10.15421/082108

Frisch, M. J., Trucks, G. W., Schlegel, H. B., Scuseria, G. E., Robb, M. A., Cheeseman, J. R., Scalmani, G., Barone, V., Mennucci, B., Petersson, G. A., Nakatsuji, H., Caricato, M., Li, X., Hratchian, H. P., Izmaylov, A. F., Bloino, J., Zheng, G., Sonnenberg, J. L., Hada, M., Ehara, M., Toyota, K., Fukuda, R., Hasegawa, J., Ishida, M., Nakajima, T., Honda, Y., Kitao, O., Nakai, H., Vreven, T., Montgomery, J. A., Jr., Peralta, J. E., Ogliaro, F., Bearpark, M., Heyd, J. J., Brothers, E., Kudin, K. N., Staroverov, V. N., Keith, T., Kobayashi, R., Normand, J., Raghavachari, K., Rendell, A., Burant, J. C., Iyengar, S. S., Tomasi, J., Cossi, M., Rega, N., Millam, J. M., Klene, M., Knox, J. E., Cross, J. B., Bakken, V., Adamo, C., Jaramillo, J., Gomperts, R., Stratmann, R. E., Yazyev, O., Austin, A. J., Cammi, R., Pomelli, C., Ochterski, J. W., Martin, R. L., Morokuma, K., Zakrzewski, V. G., Voth, G. A., Salvador, P., Dannenberg, J. J., Dapprich, S., Daniels, A. D., Farkas, O., Foresman, J. B., Ortiz, J. V., Cioslowski, J., Fox, D. J. (2013). Gaussian 09, Revision D.01.

Beketov, G. V., Shynkarenko, O. V. (2022). Surface wetting and contact angle: basics and characterization. Him. Fiz. Tehnol. Poverhni, 13(1), 3–35. https://doi.org/10.15407/hftp13.01.003

Shipatov, V. T., Seregin, P. P. (1974). Mössbauer effect and the chemical bond in compounds of tin with elements of the fifth group. Theor. Exp. Chem., 8, 343–345. https://doi.org/10.1007/BF00529172

Sukhova, О.V., Syrovatko, Yu. V. (2018). Automatization of Quantitative Structural Analysis of Composites. “The journal of Zhytomyr State Technological University”/ Engineering, 82(2), 189–194. https://doi.org/10.26642/tn-2018-2(82)-189-194

Villa, F., Marengo, M., Coninck, J. D. (2018). A new model to predict the influence of surface temperature on contact angle. Sci. Rep., 8, 6549. https://doi.org/10.1038/s41598-018-24828-8

Mettu, S., Kanungo, M., Law, K. (2013). Anomalous Thermally Induced Pinning of a Liquid Drop on a Solid Substrate. Langmuir, 29, 10665–10673. https://doi.org/10.1021/la400991y

Zhang, B., Li, H., Zhu, Z. W., Fu, H. M., Wang, A. M., Dong, C., Zhang H. F. (2013). Reaction induced anomalous temperature dependence of equilibrium contact angle of TiZr based glass forming melt on Al2O3 substrate. Materials Science and Technology, 29(3), 332–336. https://doi.org/10.1179/1743284712Y.0000000153

Varanasi, D., Aldawoudi, K. E., Baumli, P., Koncz-Horvath, D., Kaptay, G. (2021). Non-wetting to Wetting Transition Temperatures of Liquid Tin on Surfaces of Different Steel Samples Corresponding to their Spontaneous Deoxidation. Arch. Metall. Mater., 66(2), 469–476. https://doi.org/10.24425/amm.2021.135880

Popel’, S. I., Kozhurkov, V. N., Zakharova, T. V. (1971). Density and surface tension of lead tin melts and their adhesion to iron. Zaschschita metallov, 7(4), 421–426.

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).