INTENSIFICATION OF THE TECHNOLOGICAL PROCESS OF FRUIT JUICE CLARIFICATION BY THE PEO and GPAA FLOCCULANTS

DOI:

https://doi.org/10.15421/jchemtech.v32i4.307784Keywords:

polymeric flocculants, clarification, purification, fruit juice, macromolecular chains, hydrodynamic field, velocity gradient.Abstract

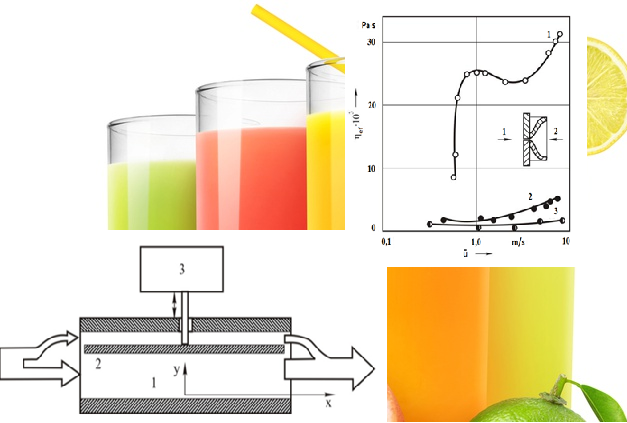

Based on the conducted research, an innovative method of fruit juice processing is proposed, which consists of using hydrodynamically activated polymeric flocculants polyethylene oxide (PEO) and hydrolysed polyacrylamide (GPAA). The mechanism of hydrodynamic control of the flocculation capacity of flocculant molecules was set up and its understanding allowed to intensify the technological process of fruit juice clarification significantly. Effective devices that allow, under conditions of convergent flow and in an oscillating hydrodynamic field, to dramatically increase the intensity of the technological process of clarification of colloidal dispersed systems, which is undoubtedly of both scientific and practical importance in solving problems of food technology and engineering ecology have been investigated. It has been proved that PEO and GPAA flocculants activated in an oscillating hydrodynamic field are promising reagents for the purification of fruit juices, for example, apple juice, due to the reduction of the content of such hazardous elements as heavy metals (arsenic, cadmium, lead, mercury, nickel) in the juice.

References

Bhattacharjee, C., Saxena, V.K., Dutta S. (2017). Fruit juice processing using membrane technology: a review. Innovative Food Science & Emerging Technologies. 43, 136–153. https://doi:10.1016/j.ifset.2017.08.002

Luo, J., Hang, X., Zhai, W., Qi, B., Song, W., Chen, X., Wan, Y. (2016). Refining sugarcane juice by an integrated membrane process: Filtration behavior of polymeric membrane at high temperature. Journal of Membrane Science. 509, 105–115. https://doi:10.1016/j.memsci.2016.02.053

Li, X., Li J, Cui, Z., Yao, Y. (2016). Modeling of filtration characteristics during submerged hollow fiber membrane microfiltration of yeast suspension under aeration condition. Journal of Membrane Science. 510, 455–465. https://doi:10.1016/j.memsci.2016.03.003

Polidori, J., Dhuique-Mayer, C., Dornier, M. (2018). Crossflow microfiltration coupled with diafiltration to concentrate and purify carotenoids and flavonoids from citrus juices. Innovative Food Science & Emerging Technologies. 45, 320–329. https://doi:10.1016/j.ifset.2017.11.015

Heshmati, A., Ghadimi, S., Ranjbar, A., Khaneghah, A.M. (2020). Assessment of processing impacts and type of clarifier on the concentration of ochratoxin A in pekmez as a conventional grape-based product. LWT Food Sci. Technol. 119, 108882.

https://doi:10.1016/j.lwt.2019.108882

Dıblan, S., Özkan, M. (2021). Effects of various clarification treatments on anthocyanins, color, phenolics and antioxidant activity of red grape juice. Food Chem. 352, 129321. https://doi:10.1016/j.foodchem.2021.129321

Talasila, U., Vechalapu, R., Shaik, K. (2012). Clarification, preservation, and shelf life evaluation of cashew apple juice. Food Science and Biotechnology, 21(3), 709–714. https://doi:10.1007/s10068-012-0092-3

Ricci, J., Delalonde, M., Wisniewski, C., Dahdouh, L. (2021). Role of dispersing and dispersed phases in the viscoelastic properties and the flow behavior of fruit juices during concentration operation. Case of orange juice. Food and Bioproducts Processing. 126, 121–129. https://doi.org/10.1016/j.fbp.2020.11.013

Machado, S., Trevisan, J.D.R., Pimentel-Souza, G.M., Pastore, M.D. (2016). Clarification and concentration of oligosaccharides from artichoke extract by a sequential process with microfiltration and nanofiltration membranes. Journal of Food Engineering. 180, 120–128. https://doi:10.1016/j.jfoodeng.2016.02.018

Ledenko, V. (2018). Trends in the juice production market. https://koloro.ua/blog/issledovaniya/tendentsii-na-rynke-proizvodstva-sokov.html

Abdullah, S., Karmakar, S., Mishra S., Pradha, R. (2023). Ultrafiltration of cashew apple juice using hollow fibers for shelf life extension: process optimization, flux modelling and storage study. Food Measure. 17, 2182–2192. https://doi.org/10.1007/s11694-022-01790-8

Urošević, T., Povrenović, D., Vukosavljević, P. Urošević, I., Stevanović, S. (2017). Recent developments in microfiltration and ultrafiltration of fruit juices, Food and Bioproducts Processing. 106, 147–161. https://doi.org/10.1016/j.fbp.2017.09.009

Kawaguchi, S., Hasegawa, S. (2014). Polymer Flocculants, Encyclopedia of Polymeric Nanomaterials, Springer-Verlag Berlin Heidelberg (outside the USA). 1–10, https://doi.org/10.1007/978-3-642-36199-9_209-1

Aluko, A., Makule, E., Kassim, N. (2023). Effect of clarification on physicochemical properties and nutrient retention of pressed and blended cashew apple juice, Food Science & Nutrition. 11(4), 1891–1903. https://doi.org/10.1002/fsn3.3222

Wongmaneepratip, W., Tongkhao, K., Vangnai, K. (2023). Effect of clarifying agent type and dose on the reduction of pyrethroid residues in apple juice, Food Control.153,109909. https://doi.org/10.1016/j.foodcont.2023.109909

Sachko, A., Kobasa, I., Moysyura, O., Vorobets, M. (2020). Efficiency of apple juice clarification with using of nano-sized mineral oxides, Ukrainian Food Journal. 9(2), 361–372. https://nuft.edu.ua/doi/doc/ufj/2020/2/8.pdf

Dimitrov, P., Hasan, E., Rangejov, S., Trzebicka, B., Dworak, A., Tsvetanov, C. (2002). High molecular weight functionalized poly(ethyleneoxide). Polymer. 43(25), 7171–7178. https://doi.org/10.1016/S0032-3861(02)00459-7

Marbelia, L., Mulier M., Vandamme, D., Muylaert, K., Szymczyk, A., Vankelecom, I.F.J. Polyacrylonitrile membranes for microalgae filtration: Influence of porosity, surface charge and microalgae species on membrane fouling. Algal Research. 19, 128–137. https://doi:10.1016/j.algal.2016.08.004.

Nones, J., Riella, H.G., Trentin, A.G., Nones, J. (2015). Effects of bentonite on different cell types: a brief review. Appl. Clay Sci. 105, 225–230. https://doi:10.1016/j.clay.2014.12.036.

Ren, M., Liu, S., Li, R., You, Y., Huang, W., Zhan, J. (2020). Clarifying effect of different fining agents on mulberry wine. Int. J. Food Sci. Technol., 55, 1578–1585. https://doi:10.1111/ijfs.14433

Romanini, E., Mcrae, J.M., Colangelo, D., Lambri, M. (2020). First trials to assess the feasibility of grape seed powder (GSP) as a novel and sustainable bentonite alternative. Food Chem., 305(125484), 1–7. https://doi:10.1016/j.foodchem.2019.125484

Ghanem, C., Taillandier, P., Rizk, M., Rizk, Z., Nehme, N., Souchard, J.P., Rayess, Y.E.l. (2017). Analysis of the impact of fining agents types, oenological tannins and mannoproteins and their concentrations on the phenolic composition of red wine. LWT Food Sci. Technol. 83, 101–109. https://doi:10.1016/j.lwt.2017.05.009

Dordoni, R., Galasi, R., Colangelo, D., De Faveri D.M., Lambri, M. (2015). Effects of fining with different bentonite labels and doses on colloidal stability and colour of a Valpolicella red wine. Int. J. Food Sci. Technol. 50, 2246–2254. https://doi:10.1111/ijfs.12875

(1999). [Decree of the Cabinet of Ministers of Ukraine, 4 January, No 12. On approval of the list of food additives permitted for use in food products (with amendments made by Decrees Cabinet of Ministers], No 342, 2000.02.17, No. 1140, 2000.07.21 http://merlin.com.ua/chem/ xarch.htm (In Ukrainian).

Pogrebnyak, A., Perkun, I., Korneyev, M., Haponenko, S., Pogrebnyak, V. (2022., Apple juice clarified by the polymeric flocculants. Food Science and Technology, 16(3), 85–91. https://doi.org/ 10.15673/fst.v16i3.2464

Pogrebnyak, A., Pogrebnyak, V., Perkun, I., Vasyliv, N. (2020), Influence of geometric and dynamic parameters of a water-polymer jet on characteristics of food products hydro-cutting process. Ukrainian Food Journal. 9(1), 197–208.

Pogrebnyak, A., Chudyk, I., Pogrebnyak, V., Perkun, I.. (2019). Coil-uncoiled chain transition of polyethylene oxide solutions under convergent flow. Chemistry and Chemical Technology. 13(4), 465–470. https://doi.org/10.23939/chcht13.04.465

Ivanyuta, Yu. F., Frenkel, S. Ya. (1992). Struktura hydrodynamychkoho polya y deformatsyonnoe povedenye makromolekul pry skhodyashchemsya techenyy. Vysokomolekulyar. soedynenyya. Ser. A, 34(3), 133–138.

Pogrebnyak, A. V., Perkun, I. V., Pogrebnyak, V. G. (2017). Degradation of Polymer Solutions in a Hydrodynamic Field with a Longitudinal Velocity Gradient. Journal of Engineering Physics and Thermophysics. 90(5), 1219–1224. https://doi:10.1007/s10891-017-1677-8

D’iakova, N. Е., Brestkin, Yu. V., Ahranova, S. F., Tverdokhleb, S.V. (1989). Birefringence effects of polymer-solutions in hydrodynamic fields, Vysokomolekulyarnye Soedineniya, Ser. B., 31(11), 844–846.

Ivanyuta, Yu. F., Naumchuk, N. V., Frenkel', S. Ya. (1985). Flow structure of aqueous solutions of polyethylene oxide in the inlet region of short capillaries. Journal of Engineering Physics. 49(4), 1192–1197. https://doi:10.1007/BF00871917

Pogrebnyak, A., Pogrebnyak, V. (2017). Mechanism of the high efficiency of the cutting frozen food products using water-jet with polymer additions. Journal of food science and technology. 11(2), 73–78. https://doi.org/10.15673/fst.v11i2.517

Ivanyuta, Yu. F., Naumchuk, I. V. (1991). Unrolling of macromolecules under wall turbulence conditions. Inzhenerno-Fizicheskii Zhurnal. 61(6), 925–927.

Pogrebnyak, A. V., Perkun, I. V., Pogrebnyak, V. G., Shimanskii, V. Y. (2021). Thermal Effects in the Flow of a Polymer Aqueous Solution Through a Hydrocutting Jet-Forming Head. Journal of Engineering Physics and Thermophysics. 94(1), 137–142. https://doi:10.1007/s10891-021-02281

Toryanik, A. I. (1977). Surface tension of aqueous solutions of acetone. Journal of Structural Chemistry. 17(3), 464–465. https://doi.org/10.1007/BF00746671

Povkh, I. L., Toryanik, A. I. (1979). Relation between molecular structure of polyethyleneoxideand drag reduction. Journal of Engineering Physics. 37(4), 1131–1136. https://doi:10.1007/BF00860980

Salyanov, V. I., Skuridin, S. G., Lortkipanidze, G. B., Chidzhavadze, Z. G., Toryanik, I. A., Evdokimov, Y. V. (1978). Relation between molekular-strukture of aqueous-solutions of polyethylene-glycol and comhaction of double-standed DNK-molecules. Molecular Biology. 12(3), 367–375.

Panov, B.S., Shevchenko, O.A., Proskurnya, Yu.A., Matlak, Ye.S., Dudik, A.M. (1999). [Geoecology of Donbass]. Probl. Ekolohyy. 1, 17–25. (In Ukrainian).

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).