AUTOMATION OF A LABORATORY ELECTRIC AUTOCLAVE USING A PROGRAMMABLE LOGIC CONTROLLER

DOI:

https://doi.org/10.15421/jchemtech.v33i1.310425Keywords:

technological parameters; electrical equipment; operating modes for sterilization of canned meat; technological process; PLC automation; food product; SCADA.Abstract

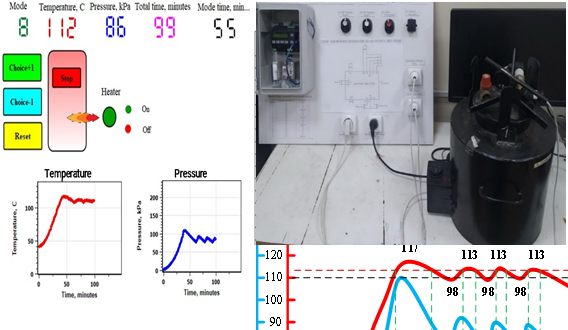

The article analyzes the use of an electric autoclave with the proposed automated control system for implementation in the educational process. An analysis of the implementation of the technological process of sterilization of canned food in an electric autoclave was carried out on the automated stand for controlling the electric autoclave called. Options for operating modes of the Programmable Logic Controller (PLC) OWEN PR200 with an electric autoclave are considered. The principle of debugging an automated stand for sterilizing canned food by students is given. It has been experimentally proven that the heating of an electric autoclave is started either by a directly programmable logic controller or by a computer with a Supervisory Control and Data Acquisition (SCADA) program. For distance learning students, there is the possibility of using remote access to monitor parameters and control the operation of the autoclave using a cloud web server. This allows students to access and control this object anywhere in the world with an Internet connection. Modeling was conducted in the MATLAB environment to determine the PLC settings, and the control system was modeled using MATLAB/Simulink. It has been studied that the electric autoclave is heated within the time specified by the technological process to the specified parameters. An example of using the stand for option №8 is given. The need to improve the quality of autoclave control has been identified. Using a Proportional-Integral-Differential (PID) regulator instead of a PLC two-position relay regulator is proposed. The advantages of using the Proportional-Integral (PI)-law regulation are presented. PID regulation through the PLC's analog output effectively produces canned food from vegetable ingredients. A further research direction may be using a controller based on fuzzy logic and its discretization.

References

Sabadash, S., Savchenko-Pererva, M., Radchuk, O., Rozhkova, L., Zahorulko, A. (2020). Improvement of equipment to intensify the drying process of dispersed food products. Eastern-European Journal of Enterprise Technologies, 11(103), 15–21, doi:10.15587/1729-4061.2020.192363.

Savchenko-Pererva, M., Yakuba, O. (2015). Improving the efficiency of devices with counter-twisting flows for the food. Eastern-European Journal of Enterprise Technologies, 8(122), 44–52, doi:10.15587/1729-4061.2023.277896.

Sukmanov, V.A., Radchuk, O.V., Savchenko-Pererva, M.Y., Budnik, N.V. (2020). Optical piezometer and precision researches of food properties at pressures from 0 to 1000 MPa. Journal of Chemistry and Technologies, 28, 68–87. https://doi.org/10.15421/082009.

Galeazzi, G., Krishnan, P., Masi, G. (2020). Application of AI-based Quality Control Systems in Food Manufacturing: A Case Study. Journal of Food Engineering, 282, 110030. https://doi.org/10.1016/j.jfoodeng.2020.110030

Panigrahi, P., Borah, S., Deka, B. C. (2019). Role of Artificial Intelligence in Enhancing Food Quality Control: A Comprehensive Review. Journal of Food Processing and Preservation, 43(4), e13829. https://doi.org/10.1111/jfpp.13829

Barsukova, H. V., Savchenko-Pererva M. Y. (2020). [Reducing the technogenic load on the environment due to the technical solution for the disposal of iron sulphate]. Journal of Chemistry and Technologies, 28(2), 168–176 (in Ukrainian). http://doi.org/ 10.15421/082018

Brown, P., Williams, J., Green, R. (2023). The Social Implications of Automation in the Food Industry. International Journal of Food Science and Technology, 58(4), 1120–1135.

Rahmani, B. (2016). Internet-based control of industrial automation systems. Journal of Intelligent & Robot Systems, 83(1), 71–83.

Nedumaran, Dr., Ritha, M. (2024). Robotics revolution: transforming the food industry through automation and innovation. SSRN Electronic Journal. 2, 165–170. doi:10.2139/ssrn.4758029.

Johnson, M., Clark, S. (2021). Ethical Challenges in Automated Livestock Management. Journal of Agricultural Ethics, 35(2), 158–172.

Chandrasiri, G.S.M., Wijenayake, A.K.I. Udara, S.P.R. (2022). Development of automated systems for the implementation of food processing. J. Res. Technol. Eng., 3(1), 8–18.

Hartulistiyoso, E., Akmal, M. (2020). Energy Usage Analysis on The Production Process of Canned Crab Meat (Portunus pelagicus). IOP Conf. Ser.: Earth Environ. Sci., 542, 012048, doi:10.1088/1755-1315/542/1/012048.

Pan, L., Pouyanfar, S., Chen, H., Qin, J., Chen, S.-C. (2017). Deep Food: Automatic Multi-Class Classification of Food Ingredients Using Deep Learning. IEEE 3rd International Conference on Collaboration and InternetComputing (CIC), 181–189, doi:10.1109/CIC.2017.00033.

Tomar, B., Kumar, N., Sreejeth, M. (2023). Real-Time Automation and Ratio Control Using PLC & SCADA in Industry 4.0. Computer Systems Science & Engineering, 45(2), 1495–1517. doi: 10.32604/csse.2023.030635

Kiangala, K. S., Wang, Z. (2019). An industry 4.0 approach to develop auto parameter configuration of a bottling process in a small to medium-scale industry using PLC and SCADA. Procedia Manufacturing, 35, 725–730.

Priyanka, H., Bhupinder, S. (2018). Importance of Electronics in Food Industry. IOSR Journal of Electronics and Communication Engineering (IOSR-JECE), 13(2), 15–22. doi: 10.9790/2834-1302021522

Barasa, S., Etene, Y. (2023). Robotics in the Food Manufacturing Industry in the Industry 4.0 Era. International Journal of Computer Science and Mobile Computing, 12, 72–77. doi:10.47760/ijcsmc.2023.v12i08.009.

Pradeep, B., Goyal, S.B., Rajawat, A., Kumar, J. Malik, S., Radhakrishnan, L. (2023). Industry Revolution 4.0: From Industrial Automation to Industrial Autonomy. In Computational Intelligence for Modern Business Systems, DTDTS. doi:10.1007/978-981-99-5354-7_17

Chakraborty, K., Choudhury, M. G., Dasc, S. & Paul, S. (2020). Development of PLC-SCADA-based control strategy for water storage in a tank for a semi-automated plant. IOP Publishing for Sissa Medialab, Journal of Instrumentation, 15(4), 1–7.

Alphonsus, E. R., Abdullah, M. O. (2016). A review on the applications of programmable logic controllers (PLCs). Renewable and Sustainable Energy Reviews, 60(3), 1185–1205.

Valadão, N., Künzel, G., Müller, I., Pereira, C. E. (2018). Industrial wireless automation: Overview and evolution of WIA-PA. IFAC-PapersOnLine, 51(10), 175–180.

Shinde, K. S., Bhagat, P. H. (2017). Industrial process monitoring using IoT. in Proc. Int. Conf. on IoT in Social, Mobile, Analytics and Cloud (I-SMAC), Palladam, India, 38–42.

Gil, S., Zapata-Madrigal, G. D., Sierra, R. G., Salazar, L.A.C. (2022). Converging IoT protocols for the data integration of automation systems in the electrical industry. Journal of Electrical Systems and Information Technology, 9(1), 1–21.

Zegzhda, D. P., Kalinin, M. O., Levykin, M. V. (2019). Actual vulnerabilities of industrial automation protocols of an open platform communications series. Automation Control and Computer Science, 53(8), 972–979.

Nadgauda, N., Muthukumaraswamy, S. A. (2019). Design and development of industrial automated system using PLC-SCADA. in Proc. IEEE 10th GCC Conf. & Exhibition (GCC), Kuwait, 1–6.

Aung, H. H., Aung, T. T. E. (2019). Simulation and implementation of PLC based for nonstop filling process using PLCSIM and HMI. International Journal of Creative and Innovative Research in All Studies, 2(3), 134–137.

Jijo, K.J., Ramesh, K.K.R. (2014). Process automation for a food processing plant. Int. J. of Scien., Engineering and Technology Research (IJSETR), 3(6), 1744–1750.

Kannan, S. (2019). Intelligent process measurement and automation: Challenges, solution and future direction. CSI Transactions on ICT, 7(5), 93–98.

Saravacos, G., Kostaropoulos, A.E. (2016). Equipment for novel food processes handbook of food processing equipment. Springer, 605–643.

Jijo, K.J., Ramesh, K.K.R. (2014). Process automation for a food processing plant. International Journal of Science, Engineering and Technology Research (IJSETR), 3(6), 1744–1750.

Christler, A., Felföldi, E., Mosor, M., Sauer, D. G. Walch, N. (2020). Semi-automation of process analytics reduces operator effect. Bioprocess and Biosystems Engineering, 43(5), 753–764.

Laing, H., Bull, S., Joyce, S., & O’Malley, C. (2021). Investigating cleaning in place (CIP) chemical, water, and energy use: A comparative study of standard operating procedure (SOP) for UK North East microbreweries. Journal of Brewing and Distilling, 10(1), 17–28.

Tomar, B., Kumar, N. (2020). PLC and SCADA based industrial automated system. IEEE Int. Conf. for Innovation in Technology (INOCON), 1–5.

Chen, R.-Y. (2017). An intelligent value structure based approach to collaboration of food traceability cyber physicalsystem by fog computing. Food Control, 71, 124–136. doi.org/10.1016/jfoodcont.2016.06.042.

Boz, Z., Erdoğdu, F. (2013). Evaluation of two-dimensional approach for computational modeling of heat and momentum transfer in liquid containing horizontal cans and experimental validation. Food and Bioproducts Processing, 91, 37–45. doi.org/10.18502/kls.v5i1.6103

Kaichenov, A., Vlasov, A., Maslov, A., Selyakov, I., Glukhykh, Yu. (2020). [Development of a model of thermal processes of an autoclave for a simulator of the process of sterilization of canned food]. KnE Life Sciences, 5(1), 437–449 (in Ukrainian).

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).