ELECTROCHEMICAL ALLOYS BASED ON IRON FAMILY METALS: THE EFFECT OF ELECTROLYSIS CONDITIONS

DOI:

https://doi.org/10.15421/jchemtech.v32i4.310727Keywords:

alloys; refractory metals; cobalt; pulse mode; current efficiency; electrolyte solution.Abstract

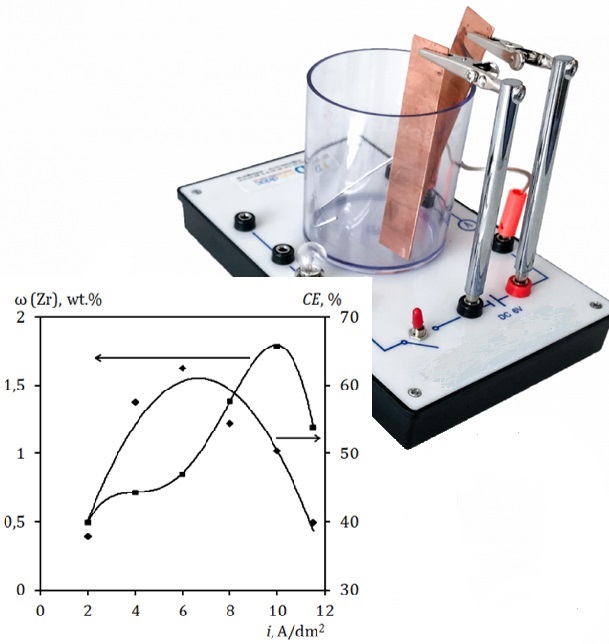

One of the main tasks of process chemists and material scientists is to create polyfunctional materials with a high level of specified properties. Controlling the structure and composition by varying the electrolysis parameters allows us to produce coatings with unique characteristics. Cobalt coatings have high hardness, corrosion resistance, reflectivity and magnetic properties. The additional inclusion of refractory components in the composition of coatings is one of the most promising ways to control their functional properties, and hence the scope of application, due to the unique physicochemical and physicomechanical properties of such alloys. The process of forming ternary Co-Ni-Zr alloys in the pulse mode from a citrate electrolyte on a copper substrate has been investigated. The effect of stirring, electrolyte pH and current density on the composition, surface morphology and current efficiency of ternary cobalt electrolytic alloys was studied. The resulting coatings are characterised by a uniform surface without cracks. The use of the pulse mode with the ratio of pulse duration 1×10-3–20×10-3 s and pause duration 2×10-3–20×10-3 s and the amplitude of cathodic current density 1–10 A/dm2 makes it possible to obtain cobalt-based alloys with zirconium content up to 2 wt. %. It was found that an increase in the acidity of the electrolyte solution does not favourably affect the current efficiency, and the dependence of the zirconium content is extreme. The modes of electrosynthesis of coatings with cobalt-nickel-zirconium alloys with a given level of surface development are substantiated.

References

Walsh, F. C., Larson, C. A. (2020). Towards improved electroplating of metal-particle composite coatings. The International Journal of Surface Engineering and Coatings, 98, 288–299. https://doi.org/10.1080/00202967.2020.1819022

Pyrig, Y., Galkin, A., Oksak, S. (2023) Influence of organic warm mix additives on properties of air blown pavement bitumen, AIP Conference Proceedings, 2490(1), 050014

Artemenko, V., Khomenko, A., Maizelis, A. (2023) Influence of Phase Composition of Zn–Ni Alloy Film on the Corrosion Resistance of Zinc Coating. Surface Engineering and Applied Electrochemistry, 59(1), 90–95. doi.org/10.3103/s1068375523010027

Lotfi, N., Aliofkhazraei, M., Rahmani, H., Darband, G.B. (2018) Zinc–nickel alloy electrodeposition: Characterization, properties, multilayers and composites, Protection of Metals and Physical Chemistry of Surfaces, 54(6), 1102–1140. https://doi.org/10.1134/S2070205118060187

Yapontseva, Yu. S., Zaichenko, V. N., Kublanovsky, V. S., Gorobets, O.Yu., Troshchenkov, Yu.M., Vyshnevskyi, O.A. (2023) Effect of a Constant Magnetic Field on Electrodeposition of CoMo, CoRe, and CoMoRe Alloys from a Citrate Electrolyte, Surface Engineering and Applied Electrochemistry, 59(4), 412–421. https://doi.org/10.3103/S106837552304018X

Maizelis, A. (2023) The Effect of Stirring on the Electrodeposition of from [(Cu–Zn) Pyrophosphate-Citrate base. Nanooptics and Photonics, Nanochemistry and Nanobiotechnology, and Their Applications: Selected Proceedings of the IX International Conference Nanotechnology and Nanomaterials (NANO2021), 280, 113–122.

Podlaha, E. J., Landolt, D. (1997) Induced codeposition: III. Molybdenum alloys with nickel, cobalt and iron. Journal of The Electrochemical Society, 144(5), 1672–1680. doi:10.1149/1.1837658

Myrzak, V., Gotelyak, A.V., and Dikusar, A.I., (2021) Size effects in the surface properties of electroplated alloys between iron group metals and tungsten, Surface Engineering and Applied Electrochemistry, 57(4), 409–418. https://doi.org/10.3103/S1068375521040128

Nenastina, Т.О., Ved, M.V., Sakhnenko, M.D., Proskurina, V.О., Zyubanova, S.І. (2021). Corrosion Resistance of Composite Coatings Based on the Alloys of Cobalt With Refractory Metals. Materials Science, 56(5), 634–641. doi: 10.1007/s11003-021-00475-9

Tsyntsaru, N., Cesiulis, H., Donten, M., Sort, J., Pellice, E., Podlaha-Murphy E. J. (2012). Modern Trends in Tungsten Alloys Electrodeposition with Iron Group Metals. Surface Eng. and Appl. Electrochemistry, 48(6), 491–520.

Zhou, F., Lu, L. Y., Yu, L. N., Xu, X. G., Jiang, Y. (2013). Multifunctional Co–Mo films fabricated by electrochemical deposition/ Electrochimica Acta. 106, 258. https://doi.org/10.1016/j.electacta.2013.05.094

Nenastina, T.O., Ved, M.V., Sakhnenko, M.D., Dacenko, V.V., Lavrova, I.O. (2021). The synthesis and photocatalytic properties of the cobalt-based composites with refractory metals. Journal of Chemistry and Technologiesthis, 28(3), 260–268. doi: 10.15421/082028

Sknar, Y.E., Sknar, I.V., Savchuk, O.O., Danilov, F.I. (2020). Electrodeposition of Ni-Co alloy from methansulfonate electrolyte. The role of the electrolyte pH in the anomalous codeposition of nickel and cobalt. Surface and Coatings Technologythis, 387, 125542. https://doi.org/10.1016/j.surfcoat.2020.125542

Sknar, Y. E., Sknar, I. V., Savchuk, O. O., Hrydnieva, T. V., Butyrina, O. D. (2023) Electrodeposition of Ni-zirconia or Ni-titania composite coatings from a methanesulfonic acid bath. Surface and Coatings Technology, 452, 129120. https://doi.org/10.1016/j.surfcoat.2022.129120

Dikusar, A.I., Belevskii, S.S. (2023) Macroscopic Size Effect in the Composition and Properties of Alloys of Iron Group Metals with Tungsten Prepared by Induced Codeposition: Alloy Deposition Mechanism and Its Implications. Engineering and Applied Electrochemistry. 59, 699–711. https://doi.org/10.3103/S106837552306008X

Sknar, Y.E., Sknar, I.V., Savchuk, O.O., Hrydnieva, T.V., Butyrina, O.D. (2023) Electrodeposition of Ni-zirconia or Ni-titania composite coatings from a methanesulfonic acid bath. Surface and Coatings Technology, 452, 129120. https://doi.org/10.1016/j.surfcoat.2022.129120

Nenastina, T.A., Ved, M.V., Sakhnenko, N.D., Proskurina, V.O., Fomina, L.P. (2020) Galvanochemical formation of functional coatings by the cobalt-tungsten-zirconium alloys. Functional Materials, 27(2), 348–353. doi.org/10.15407/fm27.02.348

Baranov, S.A., Dikusar, A.I., (2022) Kinetics of electrochemical nanonucleation during induced codeposition of iron group metals with refractory metals (W, Mo, Re), Surface Engineering and Applied Electrochemistry, 58(5), 429. https://doi.org/10.3103/S1068375522050027

Yar-Mukhamedova, G., Nenasnina, T., Ved’, M., Sakhnenko, N., Karakurkchi, A. (2022). [Nanocomposite electrolytic coatings based on cobalt alloys with refrectory metals: obtaining, properties, applications. Monograph] Almaty: Kazakh University. (In Ukrainian).

Cesiulis, H., Budreikaz, A. (2010) Electroreduction of Ni(II) and Co(II) from Pyrophosphate Solutions. Materials science. Medžiagotyra, Kaunas University of Technology, Academy of Sciences of Lithuania, 16(11), 52–56.

Oriňáková, R., Oriňák, A., Vering, G., Talian, I., Smith, R. M., Arlinghaus, H. F. (2008). Influence of pH on the electrolytic deposition of Ni-Co films. Thin Solid Films, 516, 3045–3050. https://doi.org/10.1016/j.tsf.2007.12.081

Bai, A. C. C. Hu (2002) Effects of electroplating variables on the composition and morphology of nickel-cobalt deposits plated through means of cyclic voltammetry. Electrochimica acta, 47, 3447–3456. http://dx.doi.org/10.1016/S0013-4686(02)00281-5

Yar-Mukhamedova, G. Sakhnenko, N. Nenastina, T. (2018). Electrodeposition and properties of binary and ternary cobalt alloys with molybdenum and tungsten. Applied Surface Science, 445, 298–307. doi: 10.1016/j.apsusc.2018.03.171.

Nenastina, T.A., Ved’, M.V., Sakhnenko, N.D., Proskurina, V.O. (2021) Effect of Electrolysis Conditions on the Composition and Microhardness of Ternary Cobalt Alloy Coatings. Surface Engineering and Applied Electrochemistry, 57(1), 59–66. https://doi.org/10.3103/s1068375521010099

Tsynsaru, N., Cesiulis, H., Donten, M., Sort, J., Pellicer, E., Podlaha-Murphy, E. (2012). Modern trends in tungsten alloys electrodeposition with iron group metals. Surface Engineering and Applied Electrochemistry, 48, 491 – 520. doi: 10.3103/S1068375512060038.

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).