INVESTIGATION OF THE EFFECT OF DIFFERENT PRETREATMENTS ON DRYING CHARACTERISTICS IN FREEZE DRYING OF SALMON

DOI:

https://doi.org/10.15421/jchemtech.v33i1.311068Keywords:

drying kinetics, freeze drying, seafood, Salmo salar, salmonAbstract

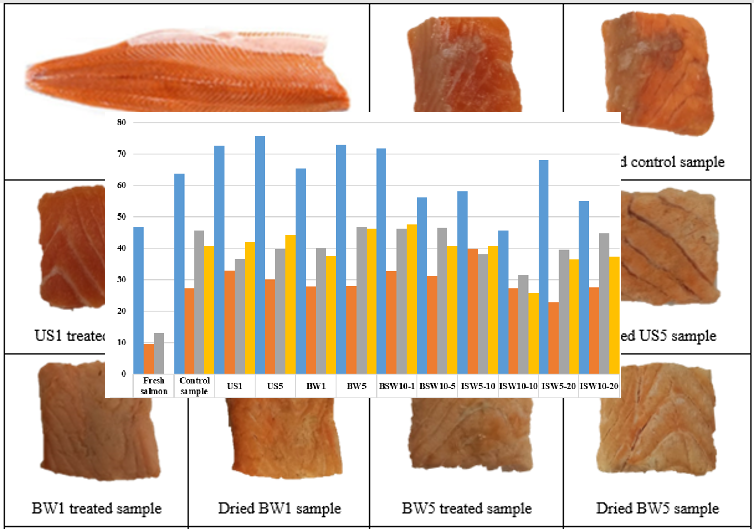

Atlantic salmon is regarded as a high-quality protein source for human consumption and is high in essential amino acids and Omega-3 fatty acids. In this study, the effect of different pretreatment applications on the drying kinetics in freeze drying of salmon was examined. The samples were treated with ten pretreatments such as blanching, blanching in saltwater, saltwater immersion, and ultrasonication at different application times and salinity rates. Drying rates and effective moisture diffusion (Deff) values of the samples were calculated and the three mathematical models showing the highest agreement among thirteen well-known models were determined. Since the preservation of color values is an important parameter in food processing, color analysis was performed to examine the color change. Drying processes were completed between 240–540 minutes and Deff values were found between 1.71–5.91×10-10 m2/s. The lowest drying time and the highest Deff value were found in the samples with blanching pre-treatment, and it was observed that the Deff value increased as the pre-treatment time increased. The most compatible model for all pretreatments and the control sample was found to be the Midilli & Kucuk model. Additionally, among the pre-treatments applied, saltwater immersion was determined to be the most effective pre-treatment in preserving color values.

References

OECD (2017). Safety Assessment of transgenic orgaisms in the environment. Volume 7: OECD Concsnsus Documents, Harmonisation of Regulatory Oversight in Biotechnology, OECD Publishing, Paris.

Forseth, T. Barlaup, BT, Finstad B. (2017). The major threats to Atlantic salmon in Norway. ICES Journal of Marine Science, 74(6), 1495–1513. https://doi.org/10.1093/icesjms/fsx020

Aas, О., Klemetsen, A., Einum, S., Skurdal, J. (Eds.). (2010). Atlantic salmon ecology. John Wiley & Sons. Blackwell Publishing Ltd, Singapore.

Davis, B. A., Devine, M. D. (2023). Evaluation of long-chain omega-3 canola oil on Atlantic salmon growth, performance, and essential fatty acid tissue accretion across the life cycle: A review. Aquaculture International, 31(5), 2559–2579. https://doi.org/10.1007/s10499-023-01099-3

Ayvaz, Z. Balaban, M., Kong, K. (2016). Effects of different brining methods on some physical properties of liquid smoked king salmon. Journal of Food Processing and Preservation, 41(1). https://doi.org/10.1111/jfpp.12791

Ortíz, J. Lemus‐Mondaca, R. Vega‐Gálvez, A. Ah-Hen, K. Puente-Díaz, L. Zura-Bravo, L. Aubourg, S. (2013). Influence of air-drying temperature on drying kinetics, colour, firmness and biochemical characteristics of Atlantic salmon (salmo salar l.) fillets. Food Chemistry, 139(1-4), 162–169. https://doi.org/10.1016/j.foodchem.2013.01.037

Halffman, C., Potter, B., McKinney, H., Finney, B., Rodrigues, A., Yang, D., Kemp, B. (2015). Early human use of anadromous salmon in north America at 11,500 y ago. Proceedings of the National Academy of Sciences, 112(40), 12344–12348. https://doi.org/10.1073/pnas.1509747112

Karagul, M.S., Altuntas, B. (2018). Liyofilizasyon: genel proses degerlendirmesi. Etlik Veteriner Mikrobiyoloji Dergisi, 29(1), 62–64. https://doi.org/10.35864/evmd.513002

Waghmarea, R. Kumar, M., Yadav, R. (2022). Application of ultrasonication as pre-treatment for freeze drying: an innovative approach for the retention of nutraceutical quality in foods. Food Chemistry, 404: 134571. https://doi.org/10.1016/j.foodchem.2022.134571

Chu, Y., Wei, S., Ding, Z., Mei, J., & Xie, J. (2021). Application of ultrasound and curing agent during osmotic dehydration to improve the quality properties of freeze-dried yellow peach (Amygdalus persica) slices. Agriculture, 11(11), 1069. https://doi.org/10.3390/agriculture11111069

Dziki, D. (2020). Recent trends in pretreatment of food before freeze-drying. Processes, 8(12), 1661. https://doi.org/10.3390/pr8121661

Jorge, A., Sauer Leal, E., Sequinel, R., Sequinel, T., Kubaski, E. T., Tebcherani, S. M. (2018). Changes in the composition of tomato powder (Lycopersicon esculentum Mill) resulting from different drying methods. Journal of food processing and preservation, 42(5), e13595. https://doi.org/10.1111/jfpp.13595

Ciurzyńska, A., Falacińska, J., Kowalska, H., Kowalska, J., Galus, S., Marzec, A., & Domian, E. (2021). The effect of pre-treatment (blanching, ultrasound and freezing) on quality of freeze-dried red beets. Foods, 10(1), 132. https://doi.org/10.3390/foods10010132

Ren, F., Perussello, C.A., Zhang, Z., Kerry, J. P., Tiwari, B.K. (2018). Impact of ultrasound and blanching on functional properties of hot-air dried and freeze dried onions. Lwt, 87, 102–111. https://doi.org/10.1016/j.lwt.2017.08.053

Wang, H. O., Fu, Q. Q., Chen, S. J., Hu, Z. C., Xie, H. X. (2018). Effect of hot-water blanching pretreatment on drying characteristics and product qualities for the novel integrated freeze-drying of apple slices. Journal of Food Quality, 2018, 1–12. https://doi.org/10.1155/2018/1347513

Ciurzyńska, A., Cichowska, J., Kowalska, H., Czajkowska, K., Lenart, A. (2018). Osmotic dehydration of Braeburn variety apples in the production of sustainable food products. International Agrophysics, 32(1). https://doi.org/10.1515/intag-2016-0099

Assis, F. R., Morais, R. M. S. C. D., Morais, A. M. M. B. D. (2018). Osmotic dehydration combined with freeze-drying of apple cubes and comparison with microwave drying and hot air drying. Advances in Food Science and Engineering, 21(1), 38–47. https://doi.org/10.22606/afse.2018.21005

Sette, P., Salvatori, D., Schebor, C. (2016). Physical and mechanical properties of raspberries subjected to osmotic dehydration and further dehydration by air-and freeze-drying. Food and bioproducts processing, 100, 156–171. https://doi.org/10.1016/j.fbp.2016.06.018

Chakraborty, N., Chakraborty, R., Saha, A. K. (2016). Dehydration of Kiwi Fruit (Actinidia deliciosa) by consecutive osmotic dehydration and freeze-drying. Indian Journal of Science and Technology, 9(28), 1–8. https://doi.org/10.17485/ijst/2016/v9i28/91839

Bhargava, N., Mor, R. S., Kumar, K., Sharanagat, V. S. (2021). Advances in application of ultrasound in food processing: A review. Ultrasonics sonochemistry, 70, 105293. https://doi.org/10.1016/j.ultsonch.2020.105293

Zhang, L., Liao, L., Qiao, Y., Wang, C., Shi, D., An, K., Hu, J. (2020). Effects of ultrahigh pressure and ultrasound pretreatments on properties of strawberry chips prepared by vacuum-freeze drying. Food Chemistry, 303, 125386. https://doi.org/10.1016/j.foodchem.2019.125386

Xu, X., Zhang, L., Feng, Y., Zhou, C., Yagoub, A. E. A., Wahia, H., Sun, Y. (2021). Ultrasound freeze-thawing style pretreatment to improve the efficiency of the vacuum freeze-drying of okra (Abelmoschus esculentus (L.) Moench) and the quality characteristics of the dried product. Ultrasonics Sonochemistry, 70, 105300. https://doi.org/10.1016/j.ultsonch.2020.105300

Merone, D., Colucci, D., Fissore, D., Sanjuan, N., Carcel, J. A. (2020). Energy and environmental analysis of ultrasound-assisted atmospheric freeze-drying of food. Journal of Food Engineering, 283, 110031. https://doi.org/10.1016/j.jfoodeng.2020.110031

Wu, X. F., Zhang, M., Ye, Y., Yu, D. (2020). Influence of ultrasonic pretreatments on drying kinetics and quality attributes of sweet potato slices in infrared freeze drying (IRFD). Lwt, 131, 109801. https://doi.org/10.1016/j.lwt.2020.109801

Deniz E., Ozyalcin Z. O., Kipcak, A. S. (2023). Investigation of the effect of blanching on the drying characteristics of freeze dried salmon. 4th International Eurasian Conference on Science, Engineering and Technology, Ankara, Türkiye, 1481–1486.

Kipcak, A.S., Doymaz, I. (2017). Microwave and infrared drying kinetics and energy consumption of cherry tomatoes. Chemical Industry and Chemical Engineering Quarterly, 26(2), 203–212. https://doi.org/10.2298/CICEQ190916039K

Sevim, S., Ozyalcin, Z.O., Kipcak, A.S. (2023). Drying and Rehydration Characteristics of Microwave Dried Mytilus edulis. Turkish Journal of Fisheries and Aquatic Sciences, 23(12), TRJFAS23601. https://doi.org/10.4194/TRJFAS23601

Nag, S., Dash, KK (2016). Mathematical modeling of thin layer drying kinetics and moisture diffusivity study of elephant apple. International Food Research Journal, 23(6), 2594–2600.

Ozyalcin, Z. O., Kipcak, A. S. (2023). Infrared and microwave drying methods on the rehydration behaviour and mass transfer diffusion coefficient of Loligo vulgaris. Sigma Journal of Engineering and Natural Sciences, 41(6), 1077-1087.

Ozyalcin, Z. O., Kipcak, A. S. (2020). The ultrasound effect on the drying characteristics of Loligo vulgaris by the methods of oven and vacuum-oven. Journal of Aquatic Food Product Technology, 31 (2), 187-199. https://doi.org/10.1080/10498850.2021.2024634

Kipcak, A.S., Ismail, O. (2021). Microwave drying of fish, chicken and beef samples. Journal of Food Science and Technology, 281–291. https://doi.org/10.1007/s13197-020-04540-0

Ozyalcin, Z. O., Kipcak, A. S., Tugrul, N. (2023). The effect of various methods on the drying kinetics and mathematical modelling of seabass (Dicentrarchus labrax). Journal of Aquatic Food Product Technology, 32(4), 384–395. https://doi.org/10.1080/10498850.2023.2227853

Kipcak, A.S., Doymaz, I. (2020). Mathematical modeling and drying characteristics investigation of black mulberry dried by microwave method. International Journal of Fruit Science, 20(3), 1222. https://doi.org/10.1080/15538362.2020.1782805

Ozyalcin, Z. O., Kipcak, A. S. (2021). The effect of ultrasonic pre-treatment on the temperature controlled infrared drying of Loligo vulgaris and comparison with the microwave drying. Turkish Journal of Fisheries and Aquatic Sciences, 21(3), 135–145. http://doi.org/10.4194/1303-2712-v21_3_04

Hunter, RS (1975). The measurement of appearance. Jone Wiley & Sons. Inc., New York.

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).