FLUOROPOLYMER MATERIALS FOR FRICTION KNOTS MODERN MACHINES AND MECHANISMS

Keywords:

фторполімери; PTFE; тертя; зношування; фрикційна взаємодія.Abstract

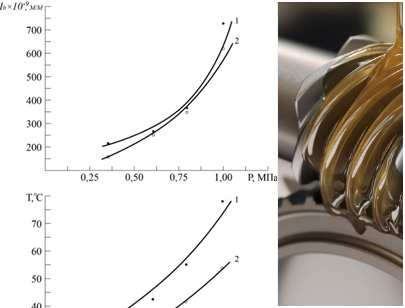

Inmodern machine-building in Ukraine, quite significant difficulties arise, which are connected with the war between Ukraine and Russia. In particular, this concerns the shortage of some polymer materials of Russian production, which were previously widely used in Ukraine. Such polymers include fluoropolymer polytetrafluoroethylene, trademark “фторопласт-4”. This material is quite widely used in friction units of machines and mechanisms. Therefore, the urgent task is to find analternative to “фторопласт-4” produced by the countries of the European Union, the USA, China, etc. Inthework, the following polytetrafluoroethylenes were chosen as an alternative to fluoroplastic-4: PTFE Powder101 and PTFE Powder161 manufactured by Stargetfluoro (Beijing, China). Studiesoftheir physico-mechanical, thermophysical and tribological properties have be enconducted and it has been establishedth at the studied materials exceed the norm at the same levelas “фторопласт-4” in term soft heir level. This allows ustoassert that PTFE Powder101 and PTFE Powder161 fluoropolymersareanalternativeto “фторопласт-4”, whicharefully capable of replacing it in the friction units of machines and mechanisms. Tribologicalstudieswerecarried out to determine the run-in path of fluoropolymers PTFE Powder101 and PTFE Powder 161, which is 250–400 m during frictional interaction with steel. The maximum load limit (up to 0.8 MPa) at which products made of the studied materials retain their performance was determined.

References

Van, B. A. (2012). Advanced Еngineering Design. Design forreliability. Delft: Delft Universityof Technology Mechanical Engineering.

Sharvan, К., Nitin, Р.Р. (2018). Materials in the Aircraft Industry.Metallurgical Design and Industry, 271–346. https://doi.org/10.1007/978-3-319-93755-7_5

Aulin, V., Lyashuk, O., Gupka, A., Tson, O., Mironov, D., Sokol, M., Leshchuk, R., Yarema, I.(2024). Tribodiagnosis of the surface damage of tribo-coupling part smaterials during machine operation. Procedia Structural Integrity, 59, 428–435. https://doi.org/10.1016/j.prostr.2024.04.061

Zakalov, O.V., Zakalov, I.O. (2011). [Basics of friction and wear in machines]. Ternopil, Ukraine: I.Puliuy National Technical University of Ternopil, 322p.

(in Ukrainian).

Kabat, O. S., Kobets, A.S., DerkachO. D., Makarenko, D.O., Hnatko, O. M. (2024). Practice of using parts made of the heat-resistant polymer composites in the chemical industry and agricultural engineering.ARPN Journal of Engineering and Applied Sciences, 19(1), 40–47.https://www.arpnjournals.org/jeas/research_papers/rp_2024/jeas_0124_9384.pdf

Кabat, О., S., Girin, O., Heti, K. (2023). Polymer composites based on aromatic polyamide and fillers of spherical and layered structure for friction units of high-performance equipment. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 237(11), 2669–2676. https://doi.org/10.1177/14644207231176796

Sytar, V., Kuzyayev, I., Kabat, O., Kudrayvtsev, A. (2023). Heat-resistant gas-filled composites based on phenylon and inorganic pore formers. Journal of Chemistry and Technologies, 31(1), 120–127. https://doi.org/10.15421/jchemtech.v31i1.268810

Kabat, O., Makarenko, D., Derkach, O., Muranov, Y. (2021). Determining the influence of the filler on the properties of structural thermal-resistant polymeric materials based on phenylone C1. Eastern-European Journal of Enterprise Technologies, 5/6(113), 24–29. https://doi.org/10.15587/1729-4061.2021.243100

Yinga, L., Xueshia, C., Zhang, J. (2024). A study on improving friction and wear performance of bearing bush in radial piston hydraulic motor. Wear, 546–547. https://doi.org/10.1016/j.wear.2024.205317

Kobets, А., Aulin, V., Derkach, O., Makarenko, D., Hrynkiv, A., Krutous, D., Muranov, E. (2020). Design of mated parts using polymeric materials with enhanced tribotechnical characteristics. Eastern-European Journal of Enterprise Technologies, 5–12(107), 49–57. https://doi.org/10.15587/1729-4061.2020.214547

He, Y., Walsh, D., Shi, C. (2015). Fluoropolymer composite coating for condensing heat exchangers: characterization of the mechanical, tribological and thermal properties. Appl Therm Eng, 91, 387–398. https://doi.org/10.1016/j.applthermaleng.2015.08.03

Danavath, В., Piyush, С. V., Suresh, K. R.N., Sujith, R., Prabakaran, S. (2024). Tribological Investigation of Chemically Modified Polytetrafluoroethylene Coating for Hydrogen Valve Application. Tribology Letters, 72(3), 72–82. https://doi.org/10.1007/s11249-024-01869-x

Kangan, Q.,Qing, P.(2024). Tribological characteristics and wear mechanisms of reinforced composites against steel. Journal of Thermoplastic Composite Materials, 37(7). https://doi.org/10.1177/089270572 3120

Shengkang, D., Zhiwei, G., Hongshuang, Z., Chengqing, Y. (2023). Effect of Silicon Carbide Particles on Tribological Properties of Polytetrafluoroethylene Water-Lubricated Bearing Composites. J. of Materi Eng and Performe, 33, 5667–5681. https://doi.org/10.1007/s11665-023-08337-y

PTFE Powder.https://stargetfluoro.com/product/ptfe-powder/

PTFE Molding Powder 101.https://stargetfluoro.com/wp-content/uploads/2023/06/PTFE-Molding-Powder-101.pdf

PTFE Molding Powder 161.https://stargetfluoro.com/wp-content/uploads/2023/ 06/PTFE-Molding-Powder-161.pdf

Kabat,_O.S., Kharchenko, B.G., Derkach, A.D., Artemchuk, V.V., Babenko, V.G. (2019). [Polymer composite materials based on fluoroplastic and the method of their production]. Voprosy Khimii i Khimicheskoi Tekhnologii, 3, 166–122. (In Russian). http://dx.doi.org/10.32434/0321-4095-2019-124-3-116-122

Kabat, O. S., Dusheiko, M. V. (2017). [Polymer composite materials for special purposes based on fluoroplastic]. Technological Systems, 4(81), 63–67. (in Ukrainian). http://dx.doi.org/10.29010/081.8

Каbаt, O.S., Derkach, O.D., Pavlushkina, N.V., Pikula, І.І.(2019). Polymeric composites of tribotechnical purpose based on fluoropolymers. Problems of Tribology, 92(2), 75–81.https://doi.org/10.31891/ 2079-1372-2019-92-2-75-81

Kabat, O.S., Heti, K. V., Kovalenko, I. L., Dudka, A. М. (2019). Fillers on the silica base for polymer composites of constructional purpose. Journal of chemistry and technologies, 27(2), 247–254. https://doi.org/10.15421/08192702

Weixuan, L., Wang, T., Wang, Q., Yap, K.K., Song, F., Wang, C. (2024). Tribological and Mechanochemical Properties of Nanoparticle-Filled Polytetrafluoro-ethylene Composites under Different Loads. Polymers, 16. https://doi.org/10.3390/polym16 070894

Sun, W., Jiaxin, Y., Yunlong, J., Xiaojun, L. (2024). Nanofiller tribochemical functionality is not sufficient to achieve ultralow wear of PTFE. Wear, 548–549. doi:10.1016/j.wear.2024.205379

Zambrano, O. A., Iglesias Guerrero, B., Rodríguez, S. A., Coronado, J. J. (2024). Running in Period During Sliding Wear of Austenitic Steels. Tribology Letters, 72. https://doi.org/10.1007/s11249-024-01867-z

Jiang, S., Qiang, L., Liu, Q., Kouediatouka, A. N., Ji, H., Dong, G. (2024). A friction mechanism for surface texturing under dry/mixed lubrication conditions based on the sublinear dependence of friction on load.Tribology International, 194.https://doi.org/10.1016/j.triboint.2024.109488

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).