IMPROVEMENT OF THE THERMODYNAMIC CYCLE OF SINGLE-STAGE STEAM COMPRESSOR REFRIGERATORS

DOI:

https://doi.org/10.15421/jchemtech.v32i3.313076Keywords:

throttling, compression work, volumetric and energy losses of the compressor, cooling coefficient, thermal pollution of the atmosphereAbstract

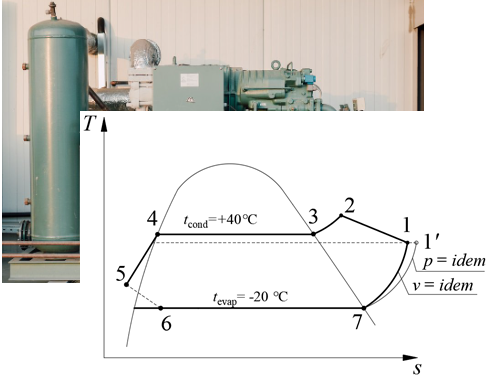

The most common device used by mankind are refrigerators. Their number on the planet Earth is significantly inferior to the number of gadgets, but significantly exceeds the number of no less common cars, the main device of which, most often, are internal combustion engines. They, producing mechanical/electrical energy, pollute the Earth's atmosphere with carcinogenic gases and heat, and refrigeration plants, using this energy, pollute the atmosphere with heat. The efficiency of both the direct (energy) cycle and the reverse (refrigeration) cycle depends on the thermodynamic cycle on which they are built. Therefore, several improvements to the thermodynamic cycle of single-stage refrigerating machines are proposed: from the simplest to the most complex, respectively, from less to more efficient. The performed comparative calculations showed that the excess of the main efficiency indicators of the refrigeration cycle with limited regenerative heat exchange over the indicators of the simplest basic cycle (without surface supercooling of the liquefied refrigerant and superheating of saturated steam) do not exceed 6 %. Exceeding similar indicators of the cycle with maximum (limit) regenerative isobaric steam overheating and polytropic process of its compression over the indicators of the cycle with limited regenerative heat exchange reach tens of percent. At the same time, exceeding the indicators of a similar cycle, but with isochoric regenerative steam overheating, reach 100 %.

References

Kirillin, V.O., Sychev, V.V., Sheindlyn, A. Ye. (1983). Technical thermodynamics. Moskva, Energoatomizdat, (in Russian)

Vasserman, O.A., Slynko, O.H. (2019). Technical thermodynamics and heat exchange. Odesa: "Phoenix" publishing house. (in Ukrainian).

Vasserman, O.A., Slynko, O.H., Shutenko, M.A. (2020). Innovative cycles of power plants. Odesa: "Phoenix" edition. (in Ukrainian).

Vasserman, O.A., Slynko, O.H. (2022). Refrigeration plants and their innovative cycles: monograph. Odesa, "Fenix" publishing house. (in Ukrainian).

McMullan, J.T. (2002) Refrigeration and the environment — issues and strategies for the future. International Journal of Refrigeration. Volume 25, Issue 1, January 2002, Pages 89-99.

https://doi.org/10.1016/S0140-7007(01)00007-X

Chen, G., Gan, Zh., Jiang, Ya. (2002). Discussion on refrigeration cycle for regenerative cryocoolers. Cryogenics. Volume 42, Issue 2, February 2002, Pages 133-139.

https://doi.org/10.1016/S0011-2275(02)00017-6

Coker, A. K. (2015). Chapter 17. Refrigeration Systems. Ludwig's Applied Process Design for Chemical and Petrochemical Plants (Fourth Edition), 623–727. https://doi.org/10.1016/B978-0-08-094242-1.00017-6

Takleh, H. R., Zare, V. (2019). Performance improvement of ejector expansion refrigeration cycles employing a booster compressor using different refrigerants: Thermodynamic analysis and optimization. International Journal of Refrigeration. Volume 101, May 2019, Pages 56-70.

https://doi.org/10.1016/j.ijrefrig.2019.02.031

Shuailing, L., Guoyuan, M., Shuxue, X., Yuexuan, G., Xiaoya, J., Guoqiang W. (2023). A review of reverse Brayton air cycle refrigerators. International Journal of Refrigeration, 150, 200–214. http://doi.org/10.1016/j.ijrefrig.2023.02.016

Yinlong, L., Qi, Ch., Guoqiang, L., Gang, Y. (2024). Energy, modified exergy, exergo-economic and exergo-environmental analyses of a separation-enhanced auto-cascade refrigeration cycle. Energy Conversion and Management. Volume 299, 1 January 2024, 117801.

https://doi.org/10.1016/j.enconman.2023.117801

Chen, L., Ge, Y., Shi, Sh., Feng, H., Liu, P. (2024) Exergetic efficiency and exergy-based ecological function performance optimizations for two irreversible simple Brayton refrigeration cycle models. Results in Engineering. Volume 22, June 2024, 101967.

https://doi.org/10.1016/j.rineng.2024.101967

Murthy, A. A., Shenoy, K. P., Krishan, G., Patil, I. S., Gangadharan, K. V., Cholleti, E. R. (2024). Advancements in dynamic simulation techniques for refrigeration cycles: A comprehensive review. Energy 360(1),100007. http://doi.org/10.1016/j.energ.2024.100007

Kitrattana, B., Aphornratana, S., Thongtip, T. (2023). Investigation on improvement potential of steam ejector performance in refrigeration cycle via constant rate of momentum change design method. Applied Thermal Engineering, 231, 120953 http://doi.org/10.1016/j.applthermaleng.2023.120953

Liu, J., Gao, Y., Lu, C., Ahmad, M. (2024). Enhancing energy and exergy performance of a cascaded refrigeration cycle: Optimization and comparative analysis. Journal of Cleaner Production, 438, 140760. http://doi.org/10.1016/j.jclepro.2024.140760

Tahmasebzadehbaie, M., Sayyaadi, H. (2020). Optimal design of a two-stage refrigeration cycle for natural gas pre-cooling in a gas refinery considering the best allocation of refrigerant. Energy Conversion and Management. Volume 210, 15 April 2020, 112743.

https://doi.org/10.1016/j.enconman.2020.112743

Liang, Y., Mckeown, A., Yu, Z., Alshammari, S. F. K. (2021). Experimental study on a heat driven refrigeration system based on combined organic Rankine and vapour compression cycles. Energy Conversion and Management, 234, 113953. https://doi.org/10.1016/j.enconman.2021.113953

Tan, Y., Wang L., Liang K. (2015). Thermodynamic performance of an auto-cascade ejector refrigeration cycle with mixed refrigerant R32 + R236fa. Aplied Thermal Engineering, 84, 268–275. http://doi.org/10.1016/j.applthermaleng.2015.03.047

Getie M. Z., Lanzetta F., Bégot S., B. Admassu, T., Hassen, A. A. (2020). Reversed regenerative Stirling cycle machine for refrigeration application: A review. International Journal of Refrigeration, 118, 173–187. http://doi.org/10.1016/j.ijrefrig.2020.06.007

Yang, Zh., Feng, B., Ma, H., Zhang, L., Duan, C., Liu, B.; Zhang, Y., Chen, S., Yang, Z. (2021). Analysis of lower GWP and flammable alternative refrigerants. International Journal of Refrigeration, 126, 12–22. http://doi.org/10.1016/j.ijrefrig.2021.01.022

Lemmon, E.W., Huber, M.L., McLinden, M.O. (2007). NIST Reference Fluid Thermodynamic and Transport Properties, REFPROP, Version 8.0, Gaithersburg.

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).