ELECTROCHEMICAL DISCHARGE OF NICKEL WITH LOW INTERNAL STRESSES

DOI:

https://doi.org/10.15421/jchemtech.v33i1.314059Keywords:

electrodeposition, nickel, sulfur-containing organic substances, kinetics, internal stressesAbstract

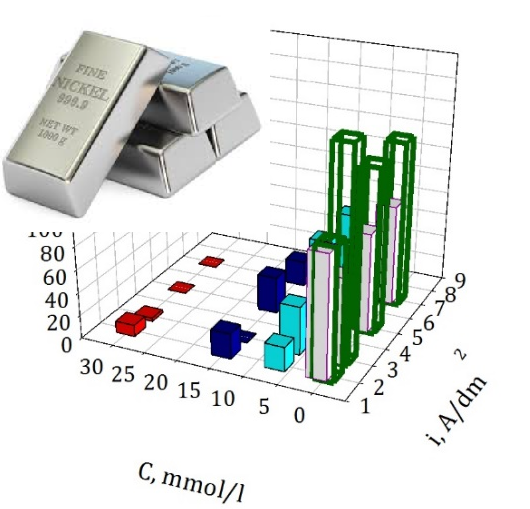

The work is devoted to the current topic of electrochemical separation of nickel with low voltages from sulfate electrolytes of electroextraction. Scrap processing of strategic nickel-containing superalloys with electroextraction of nickel is an urgent task today. Electrochemically deposited nickel is characterized by high internal tensile stresses, which leads to its delamination from the cathode surface. To reduce the internal stresses of nickel deposits obtained in such systems, it is proposed to use sulfur-containing organic compounds of sodium allylsulfonate, sodium orthoarylsulfonate, and sodium propynylsulfonate. It was established that allylsulfonate and orthoarylsulfonate practically do not affect the kinetics of nickel release. Propynyl sulfonate with a concentration of more than 5 mmol/l significantly inhibits the process of electrodeposition of nickel, which is related to the adsorption capacity of this compound with the triple bond present in the molecule. It is shown that due to the presence of a sulfo group in the composition of the molecules, the used organic additives contribute to the reduction of the internal stresses of nickel deposits. It was established that allyl sulfonate and orthoaryl sulfonate are the most promising reagents that contribute to reducing the internal stresses of electrodeposited nickel. Low-stress nickel deposits can be obtained in the range of current densities from 2 to 7 A/dm2 at a concentration of these additives from 15 to 30 mmol/l.

References

Henckens, M.L.C.M., Worrell E. (2020). Reviewing the availability of copper and nickel for future generations. The balance between production growth, sustainability and recycling rates Journal of Cleaner Production, 264, 121460. https://doi.org/10.1016/j.jclepro.2020.121460

Tian, Q.; Gan, X.; Cui, F.;Yu, D.; Guo, X. (2021). Selective Extraction of Ni from Superalloy Scraps by Molten Mg-Zn. Metals, 11, 993. https:// doi.org/10.3390/met11060993

Meshram, P., Abhilash, Pandey, B. D. (2018). Advanced review on extraction of nickel from primary and secondary sources, Mineral Processing and Extractive Metallurgy Review, 40(3), 157–193. doi: 10.1080/08827508.2018.1514300

Srivastava, R. R., Kim, M., Lee, J., Jha, M. K., Kim, B. (2014). Resource recycling of superalloys and hydrometallurgical challenges. Journal of Materials Science, 49:4671–4686. doi 10.1007/s10853-014-8219-y

Xia W., Zhao X., Yue L., Zhang Z., (2020). A review of composition evolution in Ni-based single crystal superalloys. Journal of Materials Science & Technology, 44, 76–95 https://doi.org/10.1016/j.jmst.2020.01.026.

Horst, O., Adler, D., Adler, P., Wang, H., Streitberger, J., Streitberger, M., Jöns, N., Singer, R.F., Körner, C., Eggeler, G. (2020). Exploring the fundamentals of Ni-based superalloy single crystal (SX) alloy design: Chemical composition vs. microstructure, Materials & Design, 195, 108976. https://doi.org/10.1016/j.matdes.2020.108976.

Yu, D.W., Gan, X.D., Cui, F.H., Guo, X.Y., Tian, Q.H. (2021). Dissolution behavior of nickel-based superalloy in molten zinc: Its mechanism and kinetics. J. Alloys Compd, 878, 160338.

Kim, M.S., Lee, J.C., Park, H.S., Jun M.J., Kim B.S. (2018). A multistep leaching of nickel-based superalloy scrap for selective dissolution of its constituent metals in hydrochloric acid solutions Hydrometallurgy, 176, 235–242. https://doi.org/10.1016/j.hydromet.2018.02.002

Liu, J., Tang, J., Sun, Y., Zhou, Y, Shi, F. (2024). Recovery of Ni and Co Elements from Superalloy Leaching Solution by Sodium Roasting and Water Leaching. Journal of Materials Science & Technology, 76, 3393–3401. https://doi.org/10.1007/s11837-024-06441-5

Cui, F., Wang, G., Yu, D., Gan, X., Tian, Q., Guo X. (2020). Towards “zero waste” extraction of nickel from scrap nickel-based superalloy using magnesium. Journal of Cleaner Production, 262(20), 121275. https://doi.org/10.1016/j.jclepro.2020.121275

Alvial-Hein, G., Mahandra, H., Ghahreman, A. (2021). Separation and recovery of cobalt and nickel from end of life products via solvent extraction technique: A review. Journal of Cleaner Production, 297, 126592. https://doi.org/10.1016/j.jclepro.2021.126592

Kollová, A., Pauerová, K. (2022). Superalloys – characterization, usage and recycling. Manufacturing technology, 22(5). doi: 10.21062/mft.2022.070

Kim, K., Raymond, D., Candeago, R. Su, X. (2021). Selective cobalt and nickel electrodeposition for lithium-ion battery recycling through integrated electrolyte and interface control. Nat Commun, 12, 6554. https://doi.org/10.1038/s41467-021-26814-7

Kim, K., Candeago, R., Rim, G., Raymond, D., Park, A.A., Su, X. (2021). Electrochemical approaches for selective recovery of critical elements in hydrometallurgical processes of complex feedstocks. iScience, 24(5), 102374. doi: 10.1016/j.isci.2021.102374

Choi, W.-S., Cho, S.-H., Lee, Y.-J., Kim, Y.-S., Lee, J.-H. (2015). Separation behavior of nickel and cobalt in a LiCl-KCl-NiCl2 molten salt by electrorefining process. J. Electroanal. Chem. 866, 114175. https://doi.org/10.1016/j.jelechem.2020.114175

Sknar, Y. E., Amirulloeva, N. V., Sknar, I. V., Danylov, F. I. (2016). Electrodeposition of Ni–ZrO2 Nanocomposites from Methanesulfonate Electrolytes. Materials Science, 51(6), 877–884. https://doi.org/10.1007/s11003-016-9916-2

Mieszkowska, M., Grdeń, M. (2021). Electrochemical deposition of nickel targets from aqueous electrolytes for medical radioisotope production in accelerators: a review. Journal of Solid State Electrochemistry, 25, 1699–1725. https://doi.org/10.1007/s10008-021-04950-w

Mohanty, U. S., Tripathy, B. C., Singh, P., Keshavarz A., Iglauer, S. (2019). Roles of organic and inorganic additives on the surface quality, morphology, and polarization behavior during nickel electrodeposition from various baths: a review. Journal of Applied Electrochemistr, 49, 847–870. https://doi.org/10.1007/s10800-019-01335-w

Baraniak, M.; Lota, G., Wojciechowski, J., Walkiewicz, F., Regel-Rosocka, M. (2023). Effect of Versenium Hydrogensulfate on Properties of Nickel Coatings. Materials, 16, 4101. https:// doi.org/10.3390/ma16114101

Mbugua, N.S., Kang, M., Zhang, Y., Ndiithi, N.J., Bertrand, G, Yao, L. (2020). Electrochemical Deposition of Ni, NiCo Alloy and NiCo-Ceramic Composite Coatings-A Critical Review. Materials, 6;13(16), 3475. doi: 10.3390/ma13163475

Li, Y., Yao, J., Huang, X. (2016). Effect of Saccharin on the Process and Properties of Nickel Electrodeposition from Sulfate Electrolyte. Int J Metall Mater Eng, 2, 123 http://dx.doi.org/10.15344/2455-2372/2016/123.

Kolonits T., Jenei P., Péter L, Bakonyi I., Czigány Z., Gubicza J. (2018). Surface and Coatings Technology, 349(15), 611-621. doi:10.1016/j.surfcoat.2018.06.052

Kim, S.M., Jin, S.H., Lee, Y.J., Lee, M.H. (2017). Design of nickel electrodes by electrodeposition: effect of internal stress on hydrogen evolution reaction in alkaline solutions. Electrochim Acta, 252, 67–75. https://doi.org/10.1016/j.electacta.2017.08.157

Sknar, Y., Sknar, I., Cheremysinova, A., Yermolenko, I., Karakurkchi, A., Mizin, V., Proskurina, V., Sachanova, Y. (2017). Research into composition and properties of the Ni-Fe electrolytic alloy. Eastern-European Journal of Enterprise Technologies, 4(12-88), 4–10. doi: 10.15587/1729-4061.2017.106864

Danilov F., Obraztsov V., Kapitonov A. (2003). The inhibiting effect of organic substances at polycrystalline and amalgam electrodes. J. Electroanal. Chem., 552, 69–76. doi:10.1016/S0022-0728(03)00182-7

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).