CHEMICAL AND STRUCTURAL CHARACTERISTICS AND SORPTION PROPERTIES BIOCHAR FROM WASTE COFFEE GROUNDS

DOI:

https://doi.org/10.15421/jchemtech.v33i1.316519Keywords:

waste coffee sludge; biochar; sorption properties; environmental protection technologiesAbstract

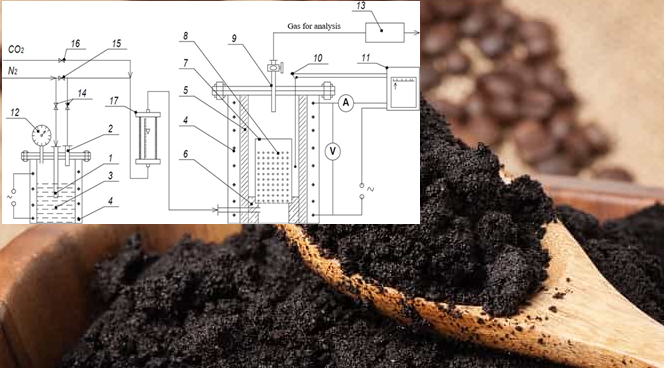

The processing of waste coffee grounds is a global problem, and its transformation into a target secondary product is an urgent and promising task. The aim of the study is to produce biochar that can be used in the process of anaerobic digestion of food waste from a hotel and restaurant complex to produce biogas and to determine its sorption characteristics. The chemical composition of the raw materials and biochar obtained by pyrolysis and microwave irradiation showed that the proportion of lignin and ash increases with increasing temperature. Studies of the interaction of lead ions with plant material and its modified forms show that sorption by biochar is much higher than by raw materials, probably due to differences in chemical composition, surface properties, etc. Comparison of the data on the sorption of lead ions by modified forms (biochar) allows us to conclude that the method of preparation has a significant effect on the sorption value. The pyrolysis temperature of the biochar has a favourable effect on the sorption properties of the samples. The obtained adsorption isotherms are of the L-type. The maximum sorption values are observed under the experimental conditions at an initial concentration of lead ions of 1.00 mg/ml. The study of the kinetic parameters of the processes of lead ion sorption by biochar preparations based on the curve of residual lead ion concentrations shows that equilibrium in the system is achieved in a few hours. The maximum sorption values are observed after 2.5-3 hours of incubation.

References

Premchand P., Demichelis F., Chiaramonti D., Bensaid S., Fino D. (2023). Study on the effects of carbon dioxide atmosphere on the production of biochar derived from slow pyrolysis of organic agro-urban waste. Waste Management Volume 172, 1 December 2023, Pages 308-319. https://doi.org/10.1016/j.wasman.2023.10.035

Awogbemi O., Vandi Von Kallon D. (2023). Progress in agricultural waste derived biochar as adsorbents for wastewater treatment. Applied Surface Science Advances Volume 18, December 2023, 100518. https://doi.org/10.1016/j.apsadv.2023.100518

Pambudi S., Saechua W., Jongyingcharoen J.S. (2024) A thermogravimetric assessment of eco-friendly biochar from oxidative torrefaction of spent coffee grounds: Combustion behavior, kinetic parameters, and potential emissions. Environmental Technology & Innovation Volume 33, February 2024, 103472. https://doi.org/10.1016/j.eti.2023.103472

International Coffee Organization, 2023. Coffee report and outlook. (Accessed December 2023). https://www.ico.org/. https://icocoffee.org/documents/cy2023-24/

Atabani A.E., Al-Muhtaseb Aa.H., Kumar G., Saratale G.D., Aslam M., Khan H.A., Said Z., Mahmoud E. (2019). Valorization of spent coffee grounds into biofuels and value-added products: pathway towards integrated bio-refinery Fuel, 254, 2019. Article 115640. https://doi.org/10.1016/j.fuel.2019.115640

Sokolova T., Krusir G., Hugi C., Breitenmoser L., Yeleuova E., Daldabayeva G., Malovanyy M., Korkach O., Sokolova V. (2024). Study of the effect of biochar from spent coffee grounds on anaerobic digestion of food waste from the restaurant industry. Journal of Chemistry and Technologies Vol. 32 No. 2 (2024): https://doi.org/10.15421/jchemtech.v32i2.297925

Jha S., Nanda S., Acharya B., Dalai A.K. (2022). A review of thermochemical conversion of waste biomass to biofuels. Energies, 15 (2022), p. 6352. https://www.scopus.com/record/display.

Rawat S., Boobalan T., Sathish M., Hotha S., Thallada B. (2023). Utilization of CO2 activated litchi seed biochar for the fabrication of supercapacitor electrodes. Biomass Bioenergy, 171 (2023), Article 106747. https://doi.org/10.1016/j.biombioe.2023.106747

Safarian S. (2023). Performance analysis of sustainable technologies for biochar production: A comprehensive review. Energy Reports Volume 9, December 2023, Pages 4574-4593. https://doi.org/10.1016/j.egyr.2023.03.111

Fenta A. A. (2024). State of the art of biochar in Ethiopia. A review. Heliyon Volume 10, Issue 3, 15 February 2024, e24934. https://doi.org/10.1016/j.heliyon.2024.e24934

Morgano M.T., Bergfeldt B., Leibold H., Richter F., Stapf D. (2018). Intermediate pyrolysis of agricultural waste: A decentral approach towards circular economy. Chem. Eng., 65 (2018). https://www.researchgate.net/publication/326031776

Mohammed I.Y., Abakr Y.A., Yusup S., Kazi F.K. (2017). Valorization of Napier grass via intermediate pyrolysis: Optimization using response surface methodology and pyrolysis products characterization. J. Clean. Prod., 142 (2017), pp. 1848-1866. https://doi.org/10.1016/j.jclepro.2016.11.099

Zhao B., O’Connor D., Zhang J., Peng T., Shen Z., Tsang D.C., Hou D. (2018). Effect of pyrolysis temperature, heating rate, and residence time on rapeseed stem derived biochar. J. Clean. Prod., 174 (2018), pp. 977-987. https://doi.org/10.1016/j.jclepro.2017.11.013

Mousa E., Wang C., Riesbeck J., Larsson M. (2016). Biomass applications in iron and steel industry: An overview of challenges and opportunities. Renew. Sustain. Energy Rev., 65 (2016), pp. 1247-1266. https://doi.org/10.1016/j.rser.2016.07.061

Huang Y.-F., Chiueh P.-T., Lo S.-L. (2016). A review on microwave pyrolysis of lignocellulosic biomass. Sustain. Environ. Res., 26 (2016), pp. 103-109. http://dx.doi.org/10.1016/j.serj.2016.04.012

Liew R.K., Nam W.L., Chong M.Y., Phang X.Y., Su M.H., Yek P.N.Y., Ma N.L., Cheng C.K., Chong C.T., Lam S.S. (2018). Oil palm waste: An abundant and promising feedstock for microwave pyrolysis conversion into good quality biochar with potential multi-applications. Process Safety and Environmental Protection, 115 (2018), pp. 57-69. https://doi.org/10.1016/j.psep.2017.10.005

Wallace C.A., Afzal M.T., Saha G.C. (2019). Effect of feedstock and microwave pyrolysis temperature on physio-chemical and nano-scale mechanical properties of biochar. Bioresour. Bioprocess., 6 (2019), pp. 1-11. https://scholar.google.com/scholar

Huang Y.-F., Chiueh P.-T., Shih C.-H., Lo S.-L., Sun L., Zhong Y., Qiu C. (2015). Microwave pyrolysis of rice straw to produce biochar as an adsorbent for CO2 capture. Energy, 84 (2015), pp. 75-82. https://doi.org/10.1016/j.energy.2015.02.026

Kostas E. T., Durán-Jiménez G., Shepherd B.J., Meredith W., Stevens L.A., Williams O.S.A., Lye G.J., Robinson J.P. (2020). Microwave pyrolysis of olive pomace for bio-oil and bio-char production. Chem. Eng. J., 387 (2020), Article 123404. https://doi.org/10.1016/j.cej.2019.123404

Hossain M.A., Jewaratnam J., Ganesan P., Sahu J., Ramesh S., Poh S. (2016). Microwave pyrolysis of oil palm fiber (OPF) for hydrogen production: parametric investigation. Energy Convers. Manage., 115 (2016), pp. 232-243. https://doi.org/10.1016/j.enconman.2016.02.058

Sahoo D., Remya N. (2020). Influence of operating parameters on the microwave pyrolysis of rice husk: biochar yield, energy yield, and property of biochar. Biomass Convers. Biorefinery (2020), pp. 1-10. https://scholar.google.com/scholar

Fodah A.E.M., Ghosal M.K., Behera D. (2021). Solar-powered microwave pyrolysis of corn stover for value-added products and process techno-economic assessment. Int. J. Energy Res., 45 (2021), pp. 5679-5694. https://doi.org/10.1002/er.6192

Neha S., Remya N. (2023). Optimization of biochar production from microwave co-pyrolysis of food waste and low-density polyethylene. Original Article Volume 13, pages 9465–9474, (2023). https://link.springer.com/article/10.1007/s13399-023-03948-w

Nyambura S. M., Li C., Li H., Xu J., Wang J., Zhu X., Feng X., Li X., Bertrand G.V., Ndumia J.N., Chin B.L.F. (2023). Microwave co-pyrolysis of kitchen food waste and rice straw: Effects of susceptor on thermal, surface, and fuel properties of biochar. Fuel Volume 352, 15 November 2023, 129093. https://doi.org/10.1016/j.fuel.2023.129093

Matrapazi V.K., Zabaniotou A. (2020). Experimental and feasibility study of spent coffee grounds upscaling via pyrolysis towards proposing an eco-social innovation circular economy solution. Science of The Total Environment. Volume 718, 20 May 2020, 137316. https://doi.org/10.1016/j.scitotenv.2020.137316

Hassan A., Ding W., Aslam M.A., Bian Y., Liu Q., Sheng Z. (2020). Microwave absorption property of coffee waste bio-carbon modified by industrial waste MnFe2O4 particles. Journal of Materials Research and Technology Volume 9, Issue 6, November–December 2020, Pages 12869-12879. https://doi.org/10.1016/j.jmrt.2020.09.015

Sharma P., Bano A., Verma K., Yadav M., Varjani S., Singh S.P., Tong Y.W. (2023). Food waste digestate as biofertilizer and their direct applications in agriculture. Bioresource Technology Reports Volume 23, September 2023, 101515. https://doi.org/10.1016/j.biteb.2023.101515

Saravanan A., Karishma S., Kumar P.S., Rangasamy G. (2023). A review on regeneration of biowaste into bio-products and bioenergy: Life cycle assessment and circular economy. Fuel Volume 338, 15 April 2023, 127221. https://doi.org/10.1016/j.fuel.2022.127221

Chiappero M., Norouzi O., Hu M., Demichelis F., Berruti F., Di Maria F., Mašek O., Fiore S. (2020). Review of biochar role as additive in anaerobic digestion processes. Re-new. Sustain. Energy Rev. https://doi.org/10.1016/j.rser.2020.110037

Qiu L., Deng Y.F., Wang F., Davaritouchaee M., Yao Y.Q. (2019). A review on biochar-mediated anaerobic digestion with enhanced methane recovery. Renew. Sustain. Energy Rev. 2019. https://doi.org/10.1016/j.rser.2019.109373

Kumar, M., Dutta, S., You, S., Luo, G., Zhang, S., Show, P.L., Sawarkar, A.D., Singh, L., Tsang, D.C.W. (2021). A critical review on biochar for enhancing biogas production from anaerobic digestion of food waste and sludge. J. Clean. Prod. 305, 127143, 2021. https://doi.org/10.1016/j.jclepro.2021.127143/

Liang J., Luo L., Li D., Varjani S., Xu Y., Wong J.W.C. (2021). Promoting anaerobic codigestion of sewage sludge and food waste with different types of conductive materi-als: performance, stability, and underlying mechanism. Bioresour. Technol. 337, 125384, 2021. https://doi.org/10.1016/j.biortech.2021.125384

Li Q., Xu M., Wang G., Chen R., Qiao W., Wang X. (2017). Biochar assisted thermo-philic co-digestion of food waste and waste activated sludge under high feedstock to seed sludge ratio in batch experiment. Bioresour. Technol. 249, 1009–1016, 2018. https://doi.org/10.1016/j.biortech.2017.11.002

Pan W., Ouyang H., Tan X., Yan S., Zhang R., Deng R., Gu L., He Q. (2023). Effects of biochar addition towards the treatment of blackwater in anaerobic dynamic membrane bioreactor (AnDMBR): Comparison among room temperature, mesophilic and thermophilic conditions. Bioresource Technology? Volume 374, April 2023, 128776/ https://doi.org/10.1016/j.biortech.2023.128776

Krusir G., Sagdeeva O., Malovanyy M., Shunko H., Gnizdovskyi O. (2020). Investigation of Enzymatic Degradation of Solid Winemaking Wastes. J. Ecol. Eng. 2020; 21(2):72-79. https://doi.org/10.12911/22998993/116345

Pillsbury D.M., Kulchar G.V., (1934). The use of the hagedorn-jensen method in the determination of skin glucose. Journal of Biological Chemistry. Volume 106, Issue 1, 1 August 1934, Pages 351-356 https://doi.org/10.1016/S0021-9258(18)75485-9

Zhang M., Song X., Deines T.W., Pei Z.J., Wang D. (2014). A consistency mapping for the effects on enzymatic hydrolysis sugar yield using two sugar yield definitions in cellulosic biofuel manufacturing. Renewable Energy Volume 62, February 2014, Pages 243-248. https://doi.org/10.1016/j.renene.2013.07.014

Aguirre, J. (2022). The Kjeldahl Method: 140 Years, Guildford, UK. https://doi.org/10.1007/978-3-031-31458-2

Zou J., Fan C., Jiang Y., Liu X., Zhou W., Xu H., Huang L. (2021) A preliminary study on assessing the Brunauer-Emmett-Teller analysis for disordered carbonaceous materials. Microporous and Mesoporous Materials, Volume 327, November 2021, 111411. https://doi.org/10.1016/j.micromeso.2021.111411ф

Tarighat M.A., Nabavi M., Mohammadizadeh M.R. (2015). Chemometrics-assisted spectrophotometric method for simultaneous determination of Pb2+ and Cu2+ ions in different foodstuffs, soil and water samples using 2-benzylspiro [isoindoline-1,5′-oxazolidine]-2′,3,4′-trione using continuous wavelet transformation and partial least squares – Calculation of pKf of complexes with rank annihilation factor analysis. Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy. Volume 145, 15 June 2015, Pages 54-62. https://doi.org/10.1016/j.saa.2015.02.048

Cherno N.K. (2010). Biocorrectors of digestive processes [Text] / N.K. Cherno, G.V. Krusir, O.V. Kovalenko / Monograph. - Odesa. - 2010. - 236 p.

Cha J.S., Park S.H., Jung S.C., Ryu C., Jeon J.K., Shin M.C., Park Y.K. (2016). Production and utilization of biochar: a review, J. Ind. Eng. Chem. 40, 2016. 1–15.

Yaashikaaa P.R., Kumar P.S., Varjani S.J., Saravanan A. (2019). Advances in production and application of biochar from lignocellulosic feedstocks for remediation of environmental pollutants, Bioresour. Technol. 292 (2019) 122030.

Sharma A., Pareek V., Zhang D. Biomass pyrolysis—a review of modelling, process parameters and catalytic studies, Renew. Sust. Energ. Rev. 50 (2015) 1081–1096.

Tenea A., Dinu C., Rus P.A., Ionescu I.A., Gheorghe S., Iancu V.I., Vasile G.G., Pascu L.F., Chiriac F.L. (2024). Exploring adsorption dynamics of heavy metals onto varied commercial microplastic substrates: Isothermal models and kinetics analysis. Heliyon. Volume 10, Issue 15. https://doi.org/10.1016/j.heliyon.2024.e35364

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).