DRYING OF PROTEIN-CAROTINE-CONTAINING RAW MATERIALS BASED ON CARROT AND FABACEAE

DOI:

https://doi.org/10.15421/jchemtech.v33i2.320931Keywords:

carotenoids; carrot; drying, drying time, heat flux densityAbstract

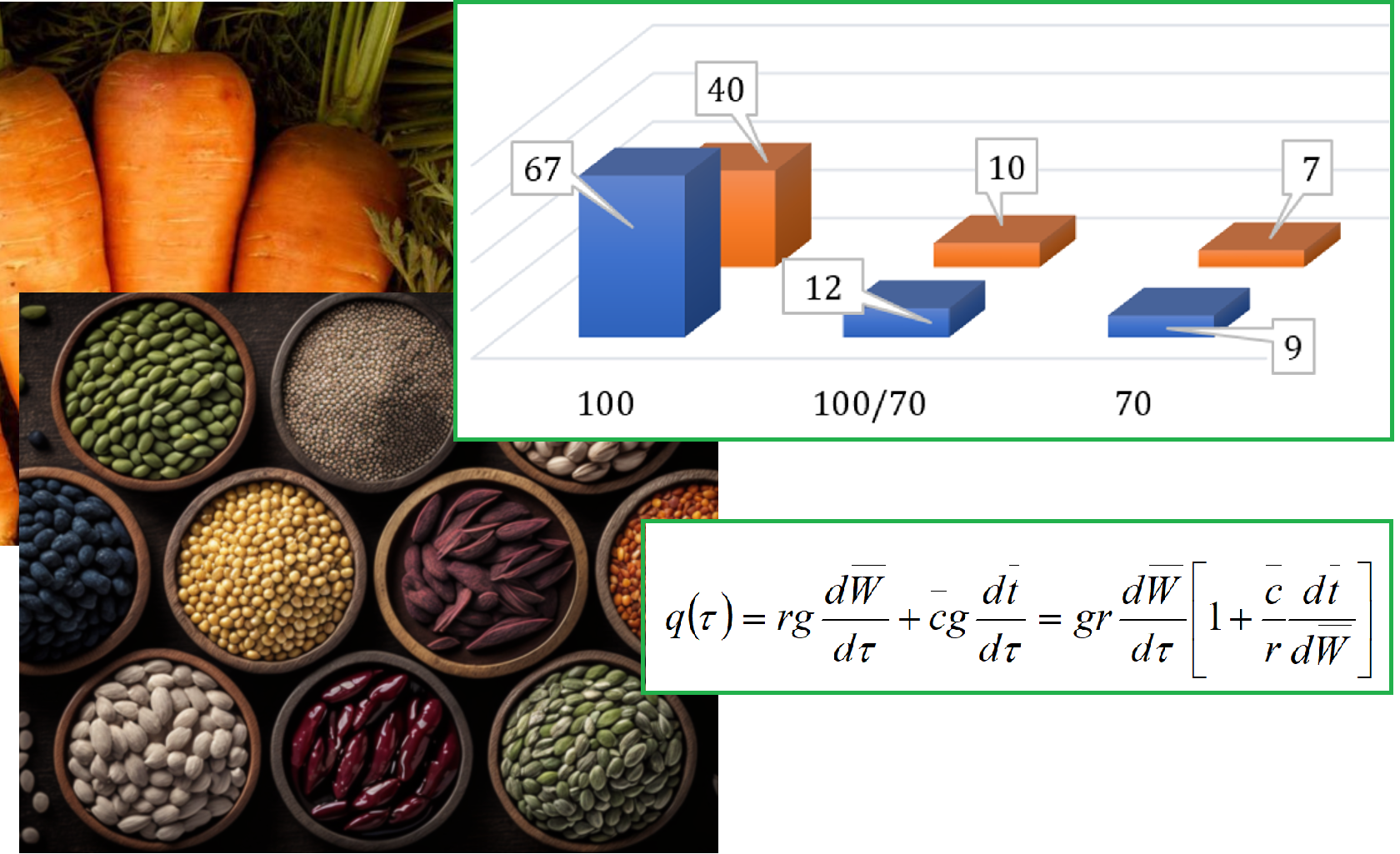

The article presents the results of research on the preliminary preparation of protein-carotene-containing raw materials based on carrots and legumes for dehydration and its effect on the physical and chemical properties of the materials studied. The research showed that carrots without pre-treatment lose up to 44 % of carotenoids. The developed blanching regimes for certain types of raw materials made it possible to reduce these losses to 1 2%. The compositions were created by combining beans, peas, and oats at a temperature of 90 °C with carrots in a ratio of 1 part protein raw material or oats to 2 parts carrots before drying. This combination reduces carotenoid losses by 4.4–5.1 %. Energy-efficient drying modes for the studied raw materials have been developed, which depend on the temperature of the heat carrier and the moisture content of the material. This is demonstrated by theoretical calculations of the optimization criterion based on experimental data.. A comparison of the experimental τexper and the calculated τteor drying duration is presented, which shows that their error does not exceed 5 %. The process duration and drying rate are calculated and a graphical differentiation of generalized curves is presented, showing the difference in the kinetics and dynamics of drying in different parts of the process. Combining the drying curves obtained under different modes into one curve confirms that the generalized drying curve adequately describes the process and does not depend on the drying mode. The kinetics of heat transfer was studied with the determination of the specific heat flux density, which showed that a decrease in the moisture content of the material reduces the heat flux density from 1.4–1.8 to 0.05–0.07 W/m2 and confirms the energy efficiency of the selected modes. Determination of the total content of carotenoids made it possible to prove that they are stored better in the compositions than in carrot powder after hygrothermal treatment by 6.3–9.6 %.

References

Akter, J., Hassan, J., Rahman, M. M., Biswas, M. S., Khan, H. I., Rajib, M. M. R., Hasan, M. F. A. (2024). Colour, nutritional composition and antioxidant properties of dehydrated carrot (Daucus carota var. sativus) using solar drying techniques and pretreatments. Heliyon, 10 (2). https://doi.org/10.1016/j.heliyon.2024.e24165

Ignaczak, A., Salamon, A., Kowalska, J., Marzec, A., Kowalska, H. (2023). Influence of Pre-Treatment and Drying Methods on the Quality of Dried Carrot Properties as Snacks. Molecules, 28(17), 6407. https://www.mdpi.com/1420-3049/28/17/6407

Kumar, R., Oruna‐Concha, M. J., Balagiannis, D. P., Niranjan, K. (2024). Elevated temperature extraction of β‐carotene from freeze‐dried carrot powder into sunflower oil: Extraction kinetics and thermal stability. Journal of Food Science, 89(3), 1642–1657. https://doi.org/10.1111/1750-3841.16964

Motegaonkar, S., Shankar, A., Tazeen, H., Gunjal, M., Payyanad, S. (2024). A comprehensive review on carrot (Daucus carota L.): the effect of different drying methods on nutritional properties and its processing as value-added foods. Sustainable

Food Technology. 2 (3), 24, 667-688 https://doi.org/10.1039/D3FB00162H

Karwacka, M., Galus, S., Janowicz, M. (2024). The effect of apple pomace powder and calcium ions on selected physicochemical properties of freeze‐dried carrot‐orange‐ginger snacks. Journal of the Science of Food and Agriculture, 104(3), 1713–1722. https://doi.org/10.1002/jsfa.13058

Ciurzyńska, A., Janowicz, M., Karwacka, M., Galus, S., Kowalska, J., Gańko, K. (2022). The Effect of Hybrid Drying Methods on the Quality of Dried Carrot. Applied Sciences, 12(20), 10588.

Imani, J., Lorenz, H., Kogel, K.-H., Glebe, D. (2007). Transgenic carrots: Potential source of edible vaccin. J. Verbr. Lebensm., 2, 105.

Arslan, A., Alibaş, İ. (2024). Assessing the effects of different drying methods and minimal processing on the sustainability of the organic food quality. Innovative Food Science & Emerging Technologies, 103681. https://doi.org/10.1016/j.ifset.2024.103681

Yusuf, E. H., Wojdyło, A., Lech, K., Masztalerz, K., Nowicka, P. (2023). The effect of combined drying process (OD-CD-VMD) on nutritional, phytochemical, and sensory profiles, and biological activities of colored dried carrot. LWT, 173, 114231. https://doi.org/10.1016/j.lwt.2022.114231

Iryna O., Huzova, Volodymyr M., Atamanyuk (2022). Dynamics of drying processes of plant raw material in the period of decreasing speed. Journal of Chemistry and Technologies 30(3), 419–430. https://doi.org/10.15421/jchemtech.v30i3.259694

Santos, N. C., Almeida, R. L. J., Monteiro, S. S.,

de Andrade, E. W. V., Saraiva, M. M. T., de Lima, T. L. B., de Almeida Mota, M. M. (2024). Potential of drying carrot using ozone pre-treatment: Mass transfer modelling and techno-functional properties. Food and Bioproducts Processing, 146, 124–134. https://doi.org/10.1016/j.fbp.2024.05.006

Fan, D., Chitrakar, B., Ju, R., Zhang, M. (2020). Effect of ultrasonic pretreatment on the properties of freeze-dried carrot slices by traditional and infrared freeze-drying technologies. Drying Technology, 39(9), 1176–1183. https://doi.org/10.1080/07373937.2020.1815765

Özbek, H. N. (2021). Radio frequency-assisted hot air drying of carrots for the production of carrot powder: Kinetics and product quality. Lwt, 152, 112332. https://doi.org/10.1016/j.lwt.2021.112332

Sniezhkin, Yu. F., Petrova, Zh. O. (2007). Heat and mass transfer processes during the production of carotene-containing powders. Kyiv: Akademperiodika.

Petrova Zh., Sniezhkin Yu. (2020) Features of the process of degidration of functional vegetable raw materials. Integration of traditional and innovation processes of development of modern science. Collective monograph, Riga, Latvia.

Dadan, M., Nowacka, M. (2021). The Assessment of the Possibility of Using Ethanol and Ultrasound to Design the Properties of Dried Carrot Tissue. Applied Sciences, 11(2), 689. https://doi.org/10.3390/app11020689

Li L., Chen X., Cao W., Liu W., Duan X., Ren G., Song C., (2024). Effects of freeze–thaw pre-treatment with different freezing methods on the microwave freeze drying of carrots, International Journal of Food Science and Technology, 59(10), 7181–7192, https://doi.org/10.1111/ijfs.17439

Xu, W., Yuan, J., Tian, J., Li, G., Sun, X., E, S., Xiao, Z. (2020). Aroma and quality of carrot dried using a microwave-convective drying system as affect by temperature gradient. International Journal of Food Properties, 23(1), 63–79. https://doi.org/10.1080/10942912.2019.1709497.

Wang, X., Han, M., Peng, C., Xie, A., Fan, X., & Liu, Y. (2024). Moisture distribution change and quality characteristics of ultrasound enhanced heat pump drying on carrot. International Journal of Food Engineering, 20(8), 583–600. https://doi.org/10.1515/ijfe-2024-0050

Srivastav, S., Shah, M., Ganorkar, P. M., Kumar, K. (2024). Modelling of electrohydrodynamic drying kinetics for carrot at varying electrode distance. Journal of Food Science and Technology, 61(1), 139–149. https://doi.org/10.1007/s13197-023-05829-6

Tadesse, T. F., Abera, S., Worku, S. (2015). Nutritional and sensory properties of solar-dried carrot slices as affected by blanching and osmotic pre-treatments. International Journal of Food Science and Nutrition Engineering, 5(1), 24–32. https://doi.org/10.5923/j.food.20150501.04

Laily, M., Asben, A., Fahmy, K. (2023). Physicochemical Characteristics of Carrot Chips (Dried Slices) with Differences in Temperature and Drying Time. AJARCDE (Asian Journal of Applied Research for Community Development and Empowerment), 95–101. https://doi.org/10.29165/ajarcde.v7i3.331

Petrova Zh.O., Sniezhkin Yu.F. (2018) Energy-efficient heat technologies for processing functional raw materials. Monograph. Naukova dumka.

Sniezhkin, Yu. F., Shapar, R. О. (2020). Energy-efficient equipment for dehydration of thermolabile materials. Thermophysics and Thermal Power Engineering, 42(2), 5–17.

Sniezhkin, Yu. F., Petrova, Zh. O., Getmaniuk, К. M., Samoilenko, О.P. (2010). Some technological characteristics of functional powders. Scientific works of the Odessa National Academy of Food Technologies, 38(2), 152–156.

Sniezhkin, Yu.F., Tszian, S., Chalaiev, D.M., Ulanov, М.М., Dabizha, N. О. (2019). Energy-saving technologies for drying thermolabile materials. Thermophysics and Thermal Power Engineering, 41(4), 5–12.

Sniezhkin, Yu. F., Petrova, Zh. O., Samoilenko, К. М., Slobodianiuk, К. S. (2022). Heat and mass transfer processes for obtaining combined functional powders. Tropea.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).