ENHANCING THE PROCESSING EFFICIENCY OF LIGHT PYROLYSIS RESIN: A MATHEMATICAL MODEL APPROACH

DOI:

https://doi.org/10.15421/jchemtech.v33i3.320966Keywords:

Student and Fisher criteria, mathematical modeling, light resin, benzene, metal-organic complex catalyst, regression model, dispersion, correlationAbstract

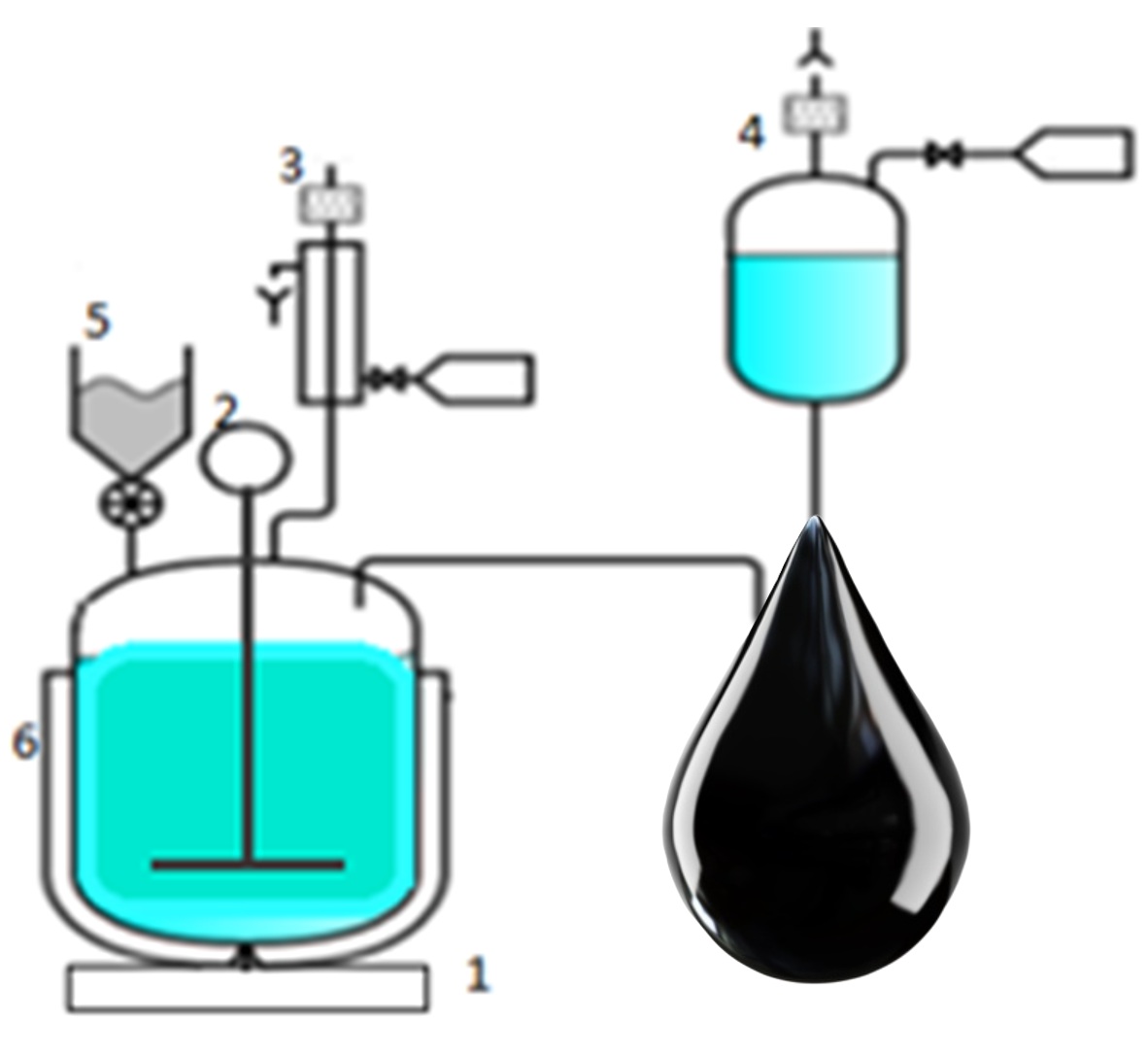

The research work is devoted to enhancing the processing efficiency of light pyrolysis rezin for ethylene production and developing a mathematical model of this process. The process is aimed at increasing the yield of benzene by dealkylation of benzene-alkyl derivatives in the system using a toluene-based aluminum complex catalyst. Calculations were performed using the OptimMe and OriginLab software packages. By studying the effect of various factors (the amount of benzene at the beginning, temperature, the amount of catalyst, the duration of the process, etc.), the optimal temperature regime of the process, the composition and amount of the catalyst, and the duration of the process corresponding to the maximum yield of benzene were selected. Using these results, a multifactorial mathematical model of the process was developed, the adequacy of the model was determined by the Fisher's criterion, and the regression coefficients were evaluated by the Student's criterion. The obtained regression enables us to estimate the yield of benzene based on any concentration of the catalyst and the temperature conditions of the process (ranging from 0 to 80 °C). and thus can be used to minimize the total costs of implementing the process. Calculations indicate that the maximum yield of benzene occurs at a temperature of 80 °C, with a catalyst concentration of 2.5 %, and a process duration of 240 minutes.

References

İbragimov, H.D., Mamedova, T.A., Amirov, F.A., İbragimova, Z.M., Akhundova, K.M., Mukhtarova, G.S. (2020). Analysis and perspectives development of liquid processing pyrolysiis products. Baku.

Abbasov, V.M., Mammadov, D.N., Rasulov, S.R., Jafarova, R.A., Abbasov, M.M. (2010). Petrochemistry and primary processing of oil. Baku.

Chen, Y., Kou, M. J., Lobo, R., Ierapetritou, M. (2024). Ethylene production: process design, technoeconomic and life-cycle assessments. Green Chemistry Journal, 26, 2903–2911. https://doi.org/10.1039/D3GC03858K

Sadrameli, S.M. (2015). Thermal/catalytic cracking of hydrocarbons for the production of olefins: A state-of-the-art review I: Thermal cracking review. Journal Fuel., 140. 102–115. https://doi.org/10.1016/j.fuel.2014.09.034

Sadrameli, S.M. (2016). Thermal/catalytic cracking of liquid hydrocarbons for the production of olefins: A state-of-the-art review II: Catalytic cracking review. Journal Fuel., 173, 285–297. https://doi.org/10.1016/j.fuel.2016.01.047

Gholami, Z., Gholami, F., Tisler, Z., Vakili, M. (2021). A Review on the Production of Light Olefins Using Steam Cracking of Hydrocarbons. Energies Journal, 14(23), 1–24. https://doi.org/10.3390/en14238190

Ahmad, A., Rafiee, M. (2023). Processes Review of Propylene Production by Catalytic Cracking of C4-C8 Olefins. Eurasian Journal of Chemical, Medicinal and Petroleum Research (EJCMPR), 2(5). 146–157. https://doi.org/10.5281/zenodo.8191914

Aliyeva, Sh. D. (2023). The study of the catalytic reforming process of light resin of pyrolysis. Azerbaijan Oil Industry Journal, 8, 63–68. doi: 10.37474/0365-8554/2023-8-63-68

Fakhroleslam, M., Sadrameli, S.M. (2020). Thermal Cracking of Hydrocarbons for the Production of Light Olefins; A Review on Optimal Process Design, Operation, and Control. Journal of Industrial and Engineering Chemistry Research, 59(27). 12287–12616. https://pubs.acs.org/doi/10.1021/acs.iecr.0c00923

Zimmermann, H., Walzl, R. (2012). Ethylene. Benchmark reference: Ullmann's Encyclopedia of Industrial Chemistry, 13. 465–526. https://doi.org/10.1002/14356007.a10_045.pub3

Abbasov, V.M., Ibrahimov, H.C., Hajiyeva, S.R., Mammadkhanova, S.A., Abdullayev, E.Sh., Amirov, F.A. (2014). Chemistry and technology of oil and gas processing processes. Baku, "Elm" publishing house.

Al-Douri, A., Sengupta, D., El-Halwagi, M.M. (2017). Shale gas monetization–a review of downstream processing to chemicals and fuels. Journal of Natural Gas Science and Engineering, 45, 436–455. http://dx.doi.org/10.1016/j.jngse.2017.05.016

Sadigov, F.M., Haciyev, G.N., Aliyeva, Sh.D., Mamedova, İ.Q., Hasan-zadeh, G.H., Melikova, E.T., Sadigova, N.S. (2022). Research of catalytic processing of light pyrolysis resin – by- product of ethylene production. Azerbaijan Chemical Journal, (4), 83–87. doi.org/10.32737/0005-2531-2022-4-83-88

SOCAR. About us. Reports. https://socar.az/en/page/reports

SOCAR. Operations, Dowstream, Ethylene-Polyethylene Plant. https://socar.az/en/page/ethylene-polyethylene-plant2

Navarro, P., Dios-García, I., Larriba, M., Delgado-Mellado, M., Ayuso, M., Moreno, D., Palomar, J., García, J., Rodriguez, F. (2019). Dearomatization of pyrolysis gasoline by extractive distillation with 1-ethyl-3-methylimidazolium tricyanomethanide. Fuel Processing Technology Journal, 195, 1–8. https://doi.org/10.1016/j.fuproc.2019.106156

Baghban, A., Nejadian, H. E., Habibzadeh, S., Ashtiani, F.Z. (2022). Hydrogenation of pyrolysis gasoline by novel Ni-doped MOF derived catalysts from ZIF-8 and ZIF-67, Scientific Reports Journal, 11, 1–12 https://doi.org/10.1038/s41598-022-24071-2

Maharramov, A.M., Bayramov, M.R. (2006). Petrochemistry and petrochemical synthesis. Baku.

Aliyeva, Sh. D. (2022). Dependence of the composition of light pyrolysis resin raw on the material of pyrolysis. XXIV International Conference of European Academy of Sciences and Research, Germany, Hamburg, 7

Sadigov, F.M., Hajiyev, G.N., Aliyeva, Sh.D., Mammadova, I.H., Hasan-zade, G.H., Malikova, E.T., Sadigova, N.S. (2023). The study of byproduct of ethylene production with light pyrolysis resin and properties of obtained varnish. Azerbaijan Oil Industry Journal, (4), 43–47. doi: 10.37474/0365-8554/ 2023-04-43-47

Sadigov, F.M., Magerramova, Z.Yu., Mamedova I.G., Haciyev G.N., Cahandarov Sh.C. (2018). Rational processing of pyrocondensate – a by-product of ethylene production. World Science Journal, 2(2(30)), 52–55.

Zhou, Z., Zeng, T., Cheng, Z., Yuan, W. (2010). Preparation of a catalyst for selective hydrogenation of pyrolysis gasoline. Industrial & Engineering Chemistry Research Journal, 49(21), 11112–11118. https://pubs.acs.org/doi/10.1021/ie1003043

Zhou, Z., Zeng, T., Cheng, Z., Yuan, W. (2011). Diffusion-enhanced hierarchically macro-mesoporous catalyst for selective hydrogenation of pyrolysis gasoline. AIChE Journal, 57, 2198–2206. https://aiche.onlinelibrary.wiley.com/doi/10.1002/aic.12421

Мanafov, M.R., Mammadov, E. M., Aliyev, G. S. (2015). Application of Software Package “OptimMe” for the Study of the Process of Partial Oxidation of Propane, American Journal of Chemistry and Application, 2(4), 47–51. http://www.aascit.org/journal/archive2?journalId=905&paperId=2260

Manafov, M.R. (2015). Development of a Software Application for Solving of Problems of Chemical Kinetics and its Implementation in a C. International Journal of Engineering and Applied Sciences (IJEAS), 2(10). 33–37. https://www.ijeas.org/download_data/IJEAS0210020.pdf

Manafov, M.R. (2016). Software application for solving some typical problems of chemical technology. Azerbaijan Chemical Journal, 6(4), 89–94. https://akj.az/en/journals/305

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).