IMPROVING THE EFFICIENCY OF VEGETABLE OIL EXTRACTION BY BIOCATALYTIC TREATMENT OF OILSEED RAW MATERIALS

DOI:

https://doi.org/10.15421/jchemtech.v33i1.322422Keywords:

meats, hydrolase complex, biocatalysis, optimization, rotational designAbstract

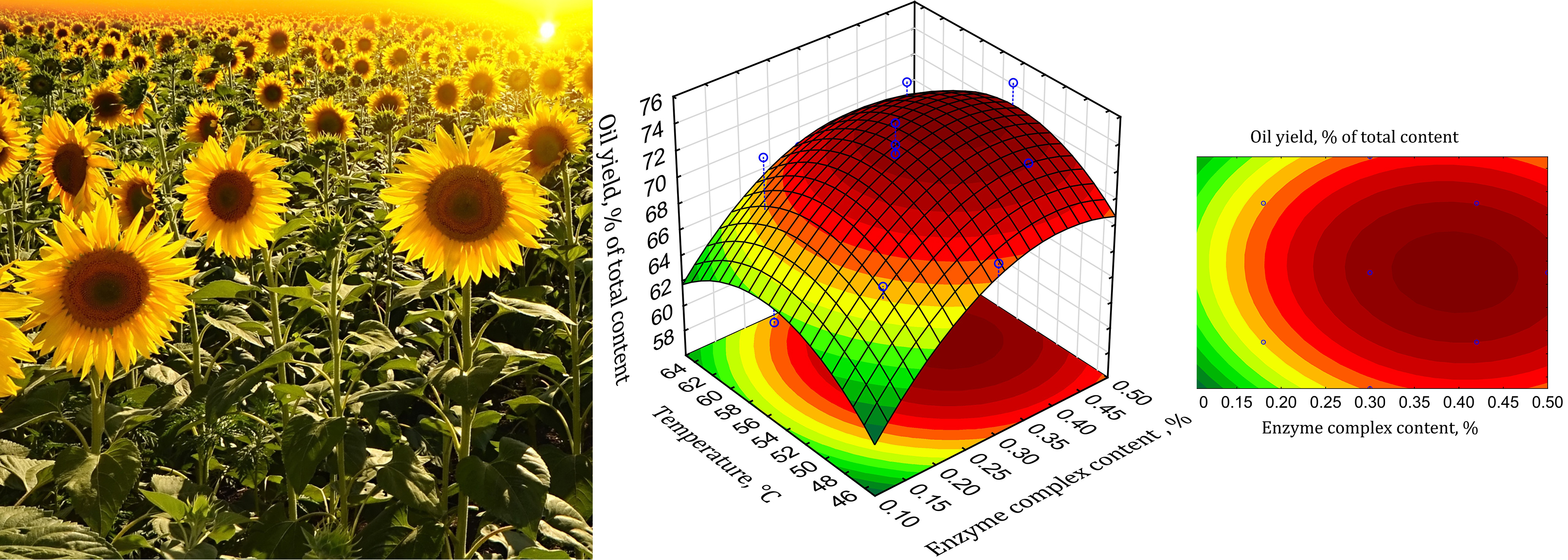

Conventional technology for processing vegetable oilseeds is typically characterized by exposing the processed product to intense heat and humidity. Such methods have an adverse effect on the beneficial components of oil-containing raw materials, irreversibly degrading the quality and yield of the resulting product, while increasing the cost of edible oil production. The above drawbacks can be eliminated through preliminary enzymatic treatment of oilseed raw materials. Owing to their protein nature, enzymes operate under mild conditions, increasing the yield of finished products, improving their quality and nutritional value. This paper suggests an improved method for preparing sunflower seed meats for pressing by treating it with a complex of enzyme agents such as Alcalase 2.4 L FG and Viscozyme L. To analyze the collected data and optimize the parameters, the response surface methodology was chosen based on the central composite rotational design. This research has shown the feasibility of using a hydrolase complex in preparing sunflower seed meats for oil extraction aimed at increasing the efficiency of the pressing process. A mathematical model has been designed to predict the oil yield based on the parameters of biocatalytic raw material treatment. We found the most suitable parameters for obtaining the maximum oil yield: the enzyme complex content was 0.37 % by the meats weight; the temperature was 57 °C; and the duration of meats treatment was 115 minutes. Under these predictor values, the product yield was 77.3 % ± 1.4 % of the total oil content of the raw material, which is almost 16 % higher than the average value of this figure for control experiments not subjected to enzymatic treatment.

References

Rani, H., Sharma, S., Bala, M. (2021). Technologies for extraction of oil from oilseeds and other plant sources in retrospect and prospects: A review. J. Food Process Eng., 44(11), e13851. https://doi.org/10.1111/jfpe.13851

Jiang, F., Yuan, L., Shu, N., Wang, W., Liu, Y., Xu, Y.-J. (2020). Foodomics Revealed the Effects of Extract Methods on the Composition and Nutrition of Peanut Oil. J. Agric. Food Chem., 68(4), 1147–1156. https://doi.org/10.1021/acs.jafc.9b06819

Hu, Z., Hu, C., Li, Y., Jiang, Q., Li, Q., Fang, C. (2024). Pumpkin seed oil: a comprehensive review of extraction methods, nutritional constituents, and health benefits. J. Sci. Food Agric., 104(2), 572–582. https://doi.org/10.1002/jsfa.12952

Riaz, T., Iqbal, M.W., Mahmood, S., Yasmin, I., Leghari, A.A., Rehman, A., Mushtaq, A., Ali, K., Azam, M., Bilal, M. (2023). Cottonseed oil: A review of extraction techniques, physicochemical, functional, and nutritional properties. Crit. Rev. Food Sci. Nutr., 63(9), 1219–1237. https://doi.org/10.1080/10408398.2021.1963206

Ferreira, I.J.B., Alexandre, E.M.C., Saraiva, J.A., Pintado, M. (2022). Green emerging extraction technologies to obtain high-quality vegetable oils from nuts: A review. Innov. Food Sci. Emerg. Technol., 76, 102931. https://doi.org/10.1016/j.ifset.2022.102931

Punia, S., Kumar, M., Siroha, A.K., Purewal, S.S. (2021). Rice Bran Oil: Emerging Trends in Extraction, Health Benefit, and Its Industrial Application. Rice Sci., 28(3), 217–232. https://doi.org/10.1016/j.rsci.2021.04.002

Ng, Y.J., Tham, P.E., Khoo, K.S., Cheng, C.K., Chew, K.W., Show, P.L. (2021). A comprehensive review on the techniques for coconut oil extraction and its application. Bioprocess Biosyst. Eng., 44(9), 1807–1818. https://doi.org/10.1007/s00449-021-02577-9

Razak, N.N.A., Cognet, P., Pérès, Y., Aroua, M.K., Gew, L.T. (2024). A decade development of lipase catalysed synthesis of acylglycerols using reactors: a systematic review. Rev. Chem. Eng., 40(7), 815–837. https://doi.org/10.1515/revce-2023-0050

Xia, S., Lin, J., Sayanjali, S., Shen, C., Cheong, L.-Z. (2024). Lipase-catalyzed production of biodiesel: a critical review on feedstock, enzyme carrier and process factors. Biofuels Bioprod. Bioref., 18 (1), 291–309. https://doi.org/10.1002/bbb.2561

Nekrasov, P.O., Gudz, O.M., Nekrasov, O.P., Berezka, T.O. (2020). Optimizing the parameters of the production process of fat systems with a minimum content of trans-isomers. Voprosy khimii i khimicheskoi technologii – Issues of Chemistry and Chemical Technology, (3), 128–133. https://doi.org/10.32434/0321-4095-2020-130-3-128-133

Cozentino, I.D.S.C., Rodrigues, M.D.F., Mazziero, V.T., Cerri, M.O., Cavallini, D.C.U., de Paula, A.V. (2022). Enzymatic synthesis of structured lipids from grape seed (Vitis vinifera L.) oil in associated packed bed reactors. Biotechnol. Appl. Biochem., 69(1), 101–109. https://doi.org/10.1002/bab.2085

Nekrasov, P.O., Berezka, T.O., Nekrasov, O.P., Gudz, O.M., Molchenko, S.M., Rudneva, S.I. (2023). Optimization of the parameters of biocatalytic hydrolysis of vegetable oil using the methods of neural networks and genetic algorithms. Journal of Chemistry and Technologies, 31(1), 140–146. https://doi.org/10.15421/jchemtech.v31i1.274704

Silva, A.R.D.M., Gonçalves, L.R.B., da Silva, I.J., Jr. (2025). Innovations in packed-bed reactors utilizing immobilized lipase catalysts: A comprehensive technical and scientific review. Mol. Catal., 573, 114814. https://doi.org/10.1016/j.mcat.2024.114814

Nekrasov, P.O., Berezka, T.O., Nekrasov, O.P., Gudz, O.M., Molchenko, S.M. (2024). Investigation of the basic laws of the kinetics of biocatalytic hydrolysis of vegetable oil. Journal of Chemistry and Technologies, 32(1), 191–197. https://doi.org/10.15421/jchemtech.v32i1.298927

Lee, Y.J., Kim, H.-W., Lee, J., Kim, B.H., Kim, I.-H. (2025). Synthesis of structured lipids using microalgae oil and capric acid via a two-step enzyme reaction. Process Biochem., 150, 213–220. https://doi.org/10.1016/j.procbio.2025.01.009

Nekrasov, P.O., Berezka, T.O., Nekrasov, O.P., Gudz, O.M., Rudneva, S.I., Molchenko, S.M. (2022). Study of biocatalytic synthesis of phytosterol esters as formulation components of nutritional systems for health purposes. Journal of Chemistry and Technologies, 30(3), 404–409. https://doi.org/10.15421/jchemtech.v30i3.265174

Nekrasov, P.O., Gudz, O.M., Nekrasov, O.P., Kishchenko, V.A., Holubets, O.V. (2019). [Fatty systems with reduced content of trans-fatty acids]. Voprosy khimii i khimicheskoi technologii – Issues of Chemistry and Chemical Technology, (3), 132–138 (in Ukrainian). https://doi.org/10.32434/0321-4095-2019-124-3-132-138

Hu, B., Li, Y., Song, J., Li, H., Zhou, Q., Li, C., Zhang, Z., Liu, Y., Liu, A., Zhang, Q., Liu, S., Luo, Q. (2020). Oil extraction from tiger nut (Cyperus esculentus L.) using the combination of microwave-ultrasonic assisted aqueous enzymatic method - design, optimization and quality evaluation. J. Chromatogr. A, 1627, 461380. https://doi.org/10.1016/j.chroma.2020.461380

Qin, Z., Chang, Y.-L., Chen, Z.-M., Wang, Y.-G., Fan, W., Gu, L.-B., Qin, Z., Liu, H.-M., Zhu, X.-L., Mei, H.-X., Wang, X.-D. (2024) A novel strategy for preparing lignan-rich sesame oil from cold-pressed sesame seed cake by combining enzyme-assisted treatment and subcritical fluid extraction. Ind. Crops Prod., 218, art. no. 119041. https://doi.org/10.1016/j.indcrop.2024.119041

Monica, P., Ranjan, R., Kapoor, M. (2024). Family 3 CBM improves the biochemical properties, substrate hydrolysis and coconut oil extraction by hemicellulolytic and holocellulolytic chimeras. Enzyme Microb. Technol., 174, 110375. https://doi.org/10.1016/j.enzmictec.2023.110375

Valladares-Diestra, K., de Souza Vandenberghe, L.P., Soccol, C.R. (2020). Oilseed Enzymatic Pretreatment for Efficient Oil Recovery in Biodiesel Production Industry: a Review. Bioenergy Res., 13(4), 1016–1030. https://doi.org/10.1007/s12155-020-10132-9

Zhang, W., Yu, J., Wang, D., Han, X., Wang, T., Yu, D. (2024). Ultrasonic-ethanol pretreatment assisted aqueous enzymatic extraction of hemp seed oil with low Δ9-THC. Ultrason. Sonochem., 103, art. no. 106766. https://doi.org/10.1016/j.ultsonch.2024.106766

Thomsen, K., Raak, N., Gregersen, S.B., Månsson, L., Miquel Becker, E. (2024) Enzyme-assisted extraction of rapeseed oil with minimum water addition: a proof-of-concept study. Int. J. Food Sci. Technol., 59 (5), 3013–3019. https://doi.org/10.1111/ijfs.17030

Atsakou, A.E., Remonatto, D., Júnior, R.H.M., Paz-Cedeno, F.R., Masarin, F., Andrade, G.S.S., de Lucca Gattas, E.A., de Paula, A.V. (2023). Synthesis of dietary lipids from pumpkin (Cucurbita pepo. L) oil obtained by enzymatic extraction: a sustainable approach. 3 Biotech, 13 (11), art. no. 358. https://doi.org/10.1007/s13205-023-03781-y

Liu, Z., Liao, H., Wei, C., Qi, Y., Zou, Z. (2023). Application of an aqueous enzymatic–ultrasound cavitation method for the separation of Sapium sebiferum seed kernel oil. Ultrason. Sonochem., 101, 106704. https://doi.org/10.1016/j.ultsonch.2023.106704

Piseskul, J., Suttisansanee, U., Chupeerach, C., Khemthong, C., Thangsiri, S., Temviriyanukul, P., Sahasakul, Y., Santivarangkna, C., Chamchan, R., Aursalung, A., On–nom, N. (2023). Optimization of Enzyme-Assisted Mechanical Extraction Process of Hodgsonia heteroclita Oilseeds and Physical, Chemical, and Nutritional Properties of the Oils. Foods, 12 (2), art. no. 292. https://doi.org/10.3390/foods12020292

Mehanni, A.E., El-Reffaei, W.H., Akdowa, E.P., Bouba, A.A. (2014). Enzyme aqueous extraction of Moringa oleifera and Canola seed oils and their effect on physiochemical characteristics and stability. Riv. Ital. Sostanze Grasse, 91 (3), 187–197.

Peng, L., Ye, Q., Liu, X., Liu, S., Meng, X. (2019). Optimization of aqueous enzymatic method for Camellia sinensis oil extraction and reuse of enzymes in the process. J. Biosci. Bioeng., 128(6), 716–722. https://doi.org/10.1016/j.jbiosc.2019.05.010

Liu, C., Hao, L.-H., Chen, F.-S., Zhu, T.-W. (2020). The mechanism of extraction of peanut protein and oil bodies by enzymatic hydrolysis of the cell wall. J. Oleo Sci., 69(11), 1467–1479. https://doi.org/10.5650/jos.ess20148

International Organization for Standardization. (2009). Oilseeds – Determination of oil content. (ISO 659:2009). Geneva, Switzerland: International Organization for Standardization.

Wu, C.F.J., Michael S. Hamada, M.S. (2021). Experiments: Planning, Analysis, and Optimization, 3rd Edition. Hoboken, USA: John Wiley & Sons Inc.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).