THE CORROSION BEHAVIOR OF Al5SiFe INTERMETALLIC PHASE

DOI:

https://doi.org/10.15421/jchemtech.v33i2.322589Keywords:

corrosion, intermetallic phase, aluminium, electrochemical studyAbstract

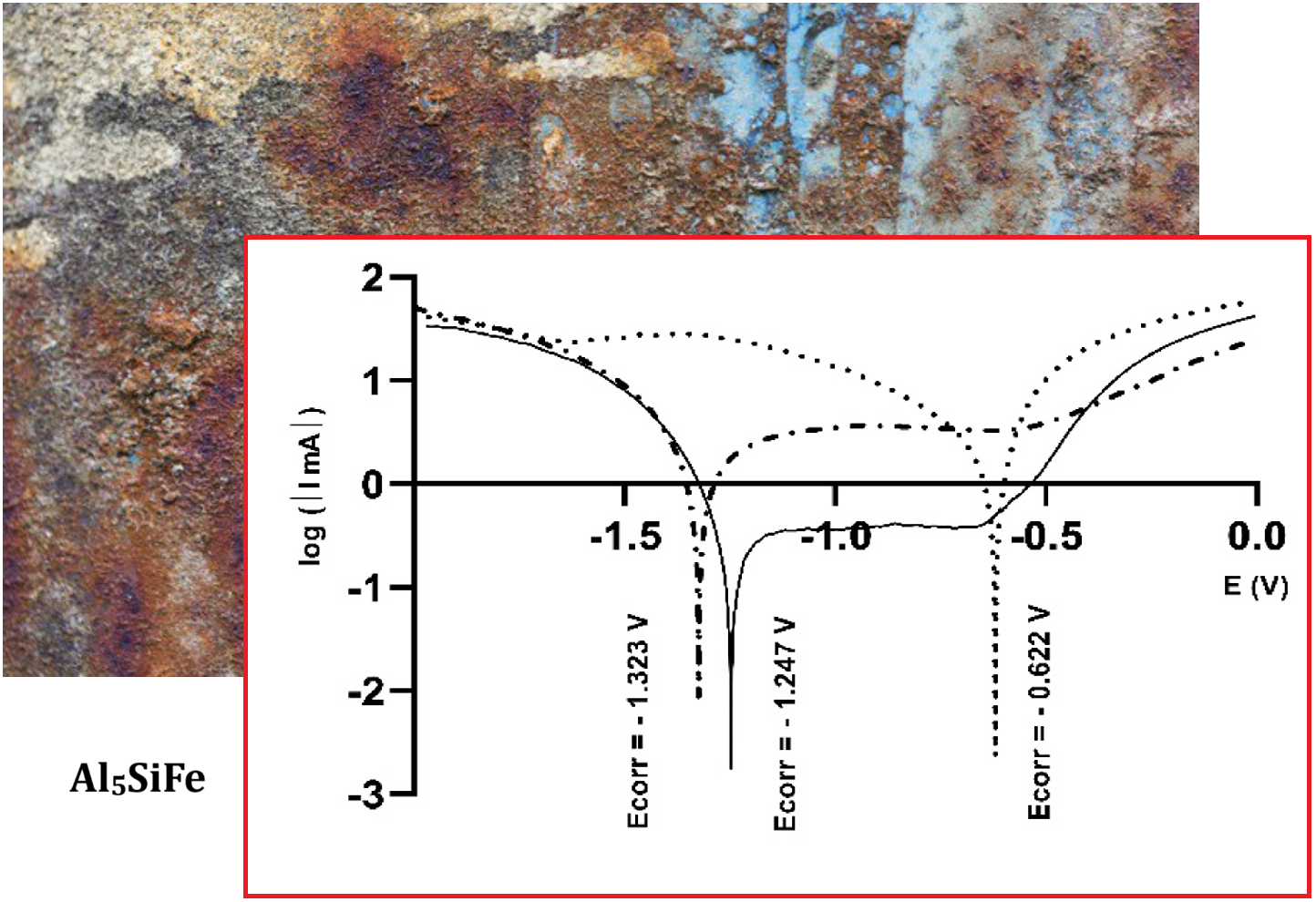

The present paper is devoted to the study of corrosion behavior of Al5SiFe intermetallic phase that frequently present in secondary aluminium alloys. It has been shown that in acidic chloride-containing solutions with pH 0.5–1.5 and 1.5–2.5, the mean weight losses, average corrosion rate, and corrosion depth index were at their maximum and temperature of the corrosive medium has a negligible effect on the corrosion rate. Increasing of corrosion medium`s pH up to neutral values resulted the decreasing of corrosion indicators. The lowest corrosion losses were detected in neutral sodium chloride solutions due to oxygen depolarization in cathodic processes and the presence of a protective film formed by corrosion products. This was confirmed by the presence of a passive region on the anodic potentiodynamic curve obtained as a result of the electrochemical study of the Al5SiFe intermetallic phase in a 3 % sodium chloride solution. Further increasing of the pH of solutions significantly accelerated the corrosion rate. This acceleration is apparently associated with the local destruction of the protective film by hydroxyl anions.

References

(2020). A Strategy for Achieving Aluminium’s Full Potential for Circular Economy by 2030. In Circular Aluminium Action Plan, European Aluminium, Brussels, Belgium, 2020.

Schwarz, H.-G. (2004). Aluminum Production and Energy in Cutler J. Cleveland (Ed.), Encyclopedia of Energy, Elsevier, 81–95.

Mitiaiev, О.А. (2008). [Scientific and technological bases of structure formation, physical, mechanical and service properties of secondary silumins.] DSc in technical sciences thesis, Zaporizhzhia. (In Ukrainian).

Narivs'kyi, O.E. (2005). Corrosion fracture of platelike heat exchangers. Fiz.-Khim. Mekh. Mater., 41(1), 104–108.

Narivs'kyi, O.E. (2007). Micromechanism of corrosion fracture of the plates of heat exchangers. Materials Science, 43(1), 124–132. https://doi.org/10.1007/s11003-007-0014-3

Mitiaiev, A.O., Belikov, S.B. (2007). [Effects of intermetallic phases on micromechanism of destruction and properties of aluminium alloys.] Mashynoznavstvo - Mechanical engineering, 3, 33–36 (In Ukrainian).

Povzlo, V.M., Volchok, I.P. (2008). [Mechanisms of corrosive destruction of secondary silumins.] Fizyko-khimichna mekhanika materialiv - Physicochemical mechanics of materials (special issue), 7(1), 59–62 (In Ukrainian).

Volchok, I.P., Mitiaiev, A.O. (2003). [The structure of the intermetallic phases and destruction resistance of silumines.] Perspektyvni zadachi inzhenernoi nauky - Perspective tasks of engineering science: Collection of scientific materials, 5, 189–193 (In Ukrainian).

Mitiaiev, О.А., Volchek, I.P., Povzlo, V.M., Loza, K.M. (2009). [Physicochemical and corrosive properties of Al5SiFe intermetallic phase.] Budivnytstvo, materialoznavstvo, mashynobudivnytstvo - Construction, materials science, mechanical engineering: Scientific materials collection, 48(1), 55–59 (In Ukrainian).

Volchok, I.P., Mitiaiev, A.O. (2006). [The resistance of secondary silumins to fatigue destruction at high loading frequencies.] Visnyk dvyhunobuduvannia - Herald of Aeroenginebuilding, 2, 175–179 (In Ukrainian).

Volchok, I.P., Sylovaniuk, V.P., Mitiaiev, O.A., Ivantyshyn, N.A. (2007). [The effects of intermetallic inclusions on durability of aluminium alloys.] Novi materialy i tekhnolohii v metalurhii ta mashynobuduvanni - New Materials and Technologies in Metallurgy and Mechanical Engineering, 2, 17–21(In Ukrainian).

Narivskyi, O.E., Subbotin, S.O., Pulina, T.V., Leoshchenko, S.D., Khoma, M.S., Ratska, N.B. (2023). Modeling of Pitting of Heat Exchangers Made of 18/10 Type Steel in Circulating Waters. Materials Science, 58(6), 748–754. https://doi.org/10.1007/s11003-023-00725-y

Narivskyi, O.E., Subbotin, S.O., Pulina, T.V., Leoshchenko, S.D., Khoma, M.S., Ratska N.B. (2023). Mechanisms of Pitting Corrosion of Austenitic Steels of Heat Exchangers in Circulating Waters and its Prediction. Materials Science, 59(3), 275–282. https://doi.org/10.1007/s11003-024-00773-y.w

Wang, J-H., Su, C.C., Szklarska-Smialowska, Z. (1988). Effects of Cl−Concentration and Temperature on Pitting of AISI 304 Stainless Steel. Corrosion, 44(10), 732–737. https://doi.org/10.5006/1.3584938

Narivskyi, O.E., Belikov, S.B. (2008). Pitting resistance of 06KhN28MDT alloy in chloride-containing media. Materials Science, 44(4), 573–580. https://doi.org/10.1007/s11003-009-9107-5

Narivskiy, A., Yar-Mukhamedova, G., Temirgaliyeva, E., Mukhtarova, M., Yar-Mukhamedov Y. (2016). Corrosion losses of alloy 06XN28MDT in chloride-containing commercial waters. Proceedings of the International Multidisciplinary Scientific GeoConference Surveying Geology and Mining Ecology Management, SGEM, Bulgaria, 63–70.

Mishchenko, V.G., Snizhnoi, G.V., Narivs'kyy, O.E. (2011). Magnetometric investigations of corrosion behaviour of AISI 304 steel in chloride-containing environment. Metallofizika i Noveishie Tekhnologii, 33(6), 769 – 774.

Narivs’kyi, O., Subbotin, S., Pulina, T. (2023). Corrosion behavior of austenitic steels in chloride-containing media during the operation of plate-like heat exchangers. Physical Sciences and Technology, 10(3-4), 48–56. https://doi.org/10.26577/phst.2023.v10.i2.06

Narivs’kiy, O.E. (2007). The influence of heterogeneity steel AISI 321 on its pitting resistance in chloride-containing media. Materials Science, 43(2), 256–264. doi: https://doi.org/10.1007/s11003-007-0029-9

Dzhus, A.V., Narivskyi, O.E., Subbotin, S.A., Pulina, T.V., Snizhnyi, G.V., Leoshchenko, S.D. (2024). Influence of components of 06KhN28MDT alloy (analogue of AISI904L steel) and parameters of model chloride-containing recycled water of enterprises on its pitting resistance. Metallophysics and Advanced Technologies, 46(4), 371–383. https://doi.org/10.15407/mfint.46.04.0371.

Narivskyi, O.E., Snizhnoi, G.V., Pulina, T.V., Snizhnoi, V.L., Solidor, N.A. (2024). Effect of Specific Magnetic Susceptibility of AISI 304 and 08Kh18N10 Steels on Their Limiting Potentials in Chloride-Containing Environments. Materials Science, 59(3), https://doi.org/10.1007/s11003-024-00824-4.

Ikeuba, A.I. (2023). Bimetallic corrosion evaluation of the pAl8Mg3FeSi6 phase/Al couple in acidic, neutral and alkaline aqueous solutions using the scanning vibrating electrode technique. Electrochim. Acta, 449, 142240. https://doi.org/10.1016/j.electacta.2023.142240

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).