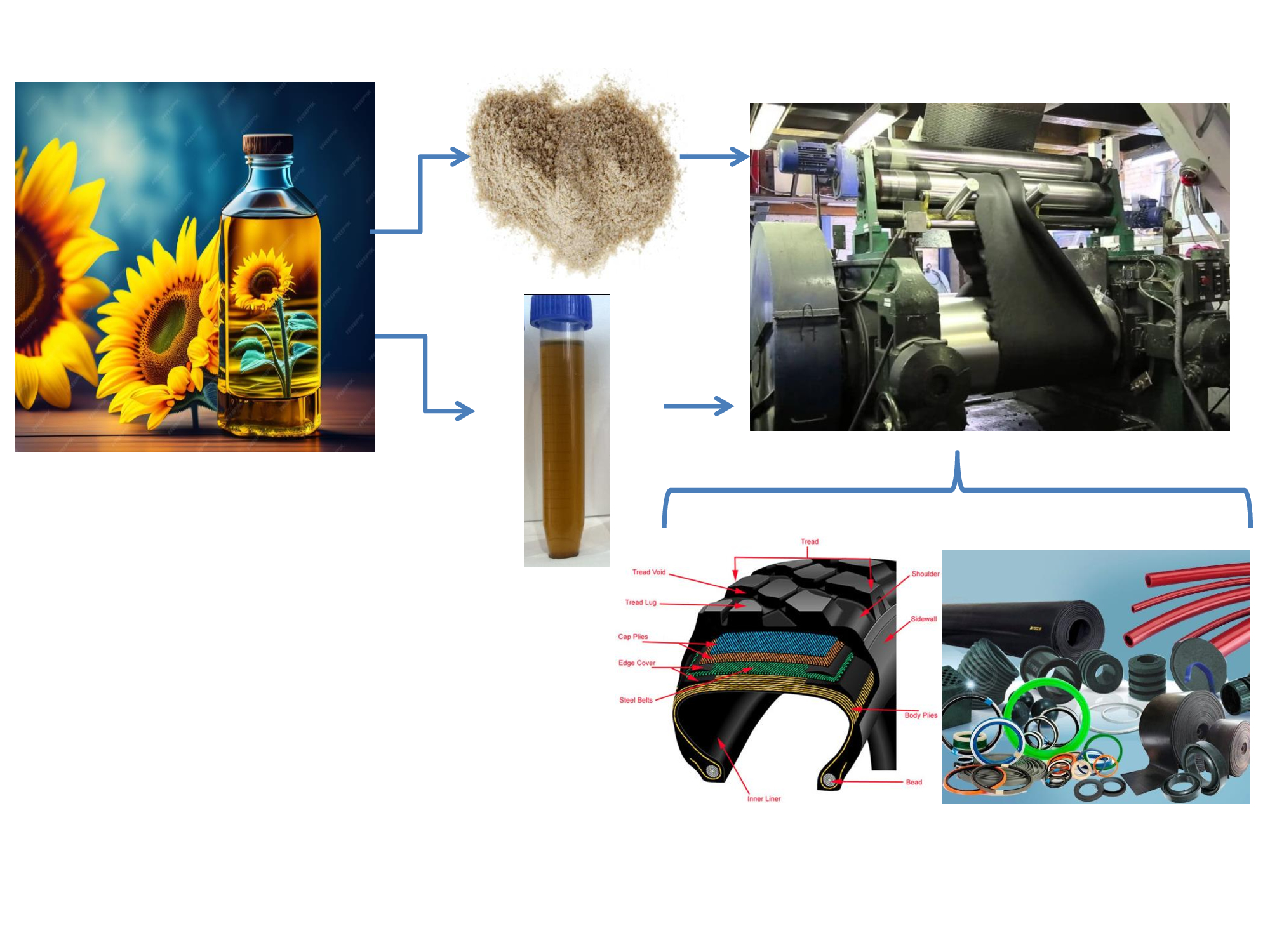

FEATURES OF ELASTOMERIC COMPOSITIONS IN THE PRESENCE OF REGENERATED SUNFLOWER OIL PRODUCTION WASTE AS FILLERS

DOI:

https://doi.org/10.15421/jchemtech.v33i2.323873Keywords:

elastomeric composition; filler; bioingredient; sunflower oil production waste; sunflower oil purification adsorbent; environmentally friendly rubber.Abstract

The paper investigates the peculiarities of the properties of elastomeric compositions based on butadiene-α-methylstyrene rubber of the Buna KER 1723 brand in the presence of regenerated sunflower oil production waste in comparison with the equal weight content (20.0 phr) of known mineral fillers. It has been shown that the hydrophobized products under study significantly affect the processibility of rubber compounds, the course of sulfur vulcanization at different temperatures, the level of rheokinetic characteristics, and the density of cross-links of elastomeric compositions. It has been established, that in terms of the rubber reinforcement factor, the spent adsorbent with 37 wt.% of the organic component (diatomite P), regenerated by two-stage washing with dichloroethane and petroleum ether, is superior to a product with 57 wt. % organic component (diatomite D), as well as chalk, but inferior to kaolin. Diatomite P can be recommended for use in industrial rubber formulations.

References

Rezić, I., Mestrović, E. (2024). Challenges of green transition in polymer production: Applications in zero energy innovations and hydrogen storage. Polymers, 16(10), 1310. http://dx.doi.org/10.3390/polym16101310

Cheng, H. N., Wu, Q., He, Z., Klasson, K. T., Jordan, J. H., Easson, M. W., Biswas, A. (2023). Sustainable Green Polymers with Agro-Based Nanomaterials: A Selected Review. Sustainable Green Chemistry in Polymer Research, 2. Sustainable Polymers and Applications, 277–288. https://doi.org/10.1021/bk-2023-1451.ch014

Ghelani, H. (2024). Sustainable manufacturing engineering: enhancing product quality through green process innovations. International Journal of Engineering and Computer Science, 11(08), 25632–25649. http://dx.doi.org/10.18535/ijecs/v11i08.4700

Martin, A.G., Jayapal, A., Vikram, K., Kavya, B. (2024) Crop residue management through utilization: A Review. Environment and еcology, 42(2B), 745–753. https://doi.org/10.60151/envec/CEAM9171

Joshi, N.C., Sinha, S., Bhatnagar, P., Nath, Y., Negi, B., Kumar, V., Gururani, P. (2024). A сoncise review on waste biomass valorization through thermochemical conversion. Current Research in Microbial Sciences, 6, 100237. https://doi.org/10.1016/j.crmicr.2024.100237

Oboh, J. O., Ajekwene, K. K., Oluwafemi, S., Ugo, U. (2023). Agricultural residues as potential diluents in natural rubber formulation. Journal of Applied Sciences and Environmental Management, 27(5), 927–932. http://dx.doi.org/10.4314/jasem.v27i5.6

Seçilmiş, Ş. S., Yanık, D. K., Fadıloğlu, S., Gögüs, F. (2021). A novel bleaching approach: Microwave assisted sunflower oil bleaching and optimization. Grasas y Aceites, 72(4), 1–9. http://dx.doi.org/10.3989/gya.1004202

Sobchenko, A. A., Kostogryz, K. P., Khvastukhin, Ju. I., Roman, S. N. (2012). Reclamation of waste oil refining materials in a steam-boiler of oils and fats factories. Energy Technologies and Resource Saving, 3, 44–48. (іn Russian)

Kalmatayeva, G. N., Sagitova, G. F., Sakibayeva, S. A., Asylbekova, D. D., Shukhanova, Zh. K. (2022). The use of related products of the fat and oil industry in the production of tire regenerate. Of the National Academy of Sciences of the Republic of Kazakhstan, 4, 46–57. https://doi.org/10.32014/2518-1491.133

Sagitova, G. F., Kalmatayeva, G. N., Sakibayeva, S. A., Asylbekova, D. D., Sadyrbayeva, A. S., Shukhanova, Zh. K. (2023). Modification of tyre rubber crumb with wastes of plant oil production. Advances in Polymer Technology, 12(35), 1–8. https://doi.org/10.1155/2023/6889286

Kalmatayeva, G. N., Sagitova, G. F., Sakibayeva, S. A., Asylbekova, D. D., Shukhanova, Zh. K. (2024). Physico-mechanical properties of vulcanizates containing waste from the fat and oil industry. Bulletin of Shakarim University Technical Sciences, 1(2(14)), 527–535. https://doi.org/10.53360/2788-7995-2024-2(14)-63

Ovcharov, V. I., Myronyuk, A. V., Sokolova, L. A., Sukha, I. V. (2020). The use of the adsorbent for cleaning of sunflower oil as a filler for elastomeric compositions. Voprosy khimii i khimicheskoi tekhnologii, 5, 53–62. https://doi.org/10.32434/0321-4095-2020-132-5-53-62

Sokolova, L., Daliba, O., Sukha, I., Skrypkina, M., Ovcharov, V. (2023). Formation of elastomeric composition properties in the presence of bioingredient. Chemistry & Chemical Technology, 17(1), 88–100. http://dx.doi.org/10.23939/chcht17.01.088

Sokolova, L. O., Sukha, I. V., Panfilova, O. A., Ovcharov, V. I., Tyshchenko, V. O. (2024). Use of sunflower oil production regenerated waste as part of elastomer compositions for the tyre elements manufacturing. Journal of Chemistry and Technologies, 32(1), 210–222. https://doi.org/10.15421/jchemtech.v32i1.297251

Lamastra, F. R., Mori, S., Cherubini, V., Scarselli, M., Nanni, F. (2017). A new green methodology for surface modification of diatomite filler in elastomers. Materials Chemistry and Physics, 194, 253–260. http://dx.doi.org/10.1016/j.matchemphys.2017.03.050

Wu, W., Cong, S. (2019). Silica- and diatomite-modified fluorine rubber nanocomposites. Bulletin of Materials Science, 42(4), 176–186. http://dx.doi.org/10.1007/s12034-019-1867-4

Cheremisinoff, N. P., Cheremisinoff, P. N. (2019) Elastomer Technology Handbook. 1st Ed. Boca Ration, United States of America: CRC Press. https://doi.org/10.1201/9780138758851

Bhowmick, A. K. (2019). Current Topics in Elastomers Research. 1st Ed. Boca Ration, United States of America: CRC Press. https://doi.org/10.1201/9781420007183

Ovcharov, V. I., Sokolova, L. O., Panfilova, O. A. (2023). Transfer of methods for determining the vulcanization characteristics of elastomeric compositions. Science, technologies, innovations, 3(27), 96–106. http://doi.org/10.35668/2520-6524-2023-3-09

Dontsov, A. A. (1978). Protsessyi strukturirovaniya elastomerov. Moskva : Himiya. P. 222-261. (in Russian).

Milani, G., Milani, F. (2017). Closed form numerical approach for a kinetic interpretation of high-cis polybutadiene rubber vulcanization with sulphur. Journal of Mathematical Chemistry, 55(2), 552–583. https://link.springer.com/article/10.1007/s10910-016-0695-7

Milani, G., Milani, F. (2020). Relation between activation energy and induction in rubber sulfur vulcanization: An experimental study. Journal of Applied Polymer Science, 138(12), 573–584. http://dx.doi.org/10.1002/app.50073

Ghosh, R., Mani, C., Krafczyk, R., Schnell, R., Talma, A., Blume, A., Dierkes, W. K. (2024). Exploring the impact of reinforcing filler systems on devulcanizate composites. Polymers, 16(11), 1448. https://doi.org/10.3390/polym16111448

Utrera-Barrios, S., Perera, R., León, N., Santana, M. H., Martínez, N. (2021). Reinforcement of natural rubber using a novel combination of conventional and in situ generated fillers. Composites Part C: Open Access, 5, 100133. https://doi.org/10.1016/j.jcomc.2021.100133

Phumnok, E., Khongprom, P., Ratanawilai, S. (2022). Preparation of natural rubber composites with high silica contents using a wet mixing process. ACS Omega, 7(10), 8364–8376. https://doi.org/10.1021/acsomega.1c05848

Lee, S.-H., Park, G.-W., Kim, H.-J., Chung, K., Jang, K.-S. (2022). Effects of filler functionalization on filler-embedded natural rubber/ethylene-propylene-diene monomer composites. Polymers, 14(17), 3502. http://dx.doi.org/10.3390/polym14173502

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).