CUTTING FOOD PRODUCTS WITH A WATER-POLYMER JET: SCIENTIFIC AND PRACTICAL ASPECTS

DOI:

https://doi.org/10.15421/jchemtech.v33i4.325223Keywords:

relaxation time; longitudinal velocity gradient; jet; pressure; polyethylene oxide; food products.Abstract

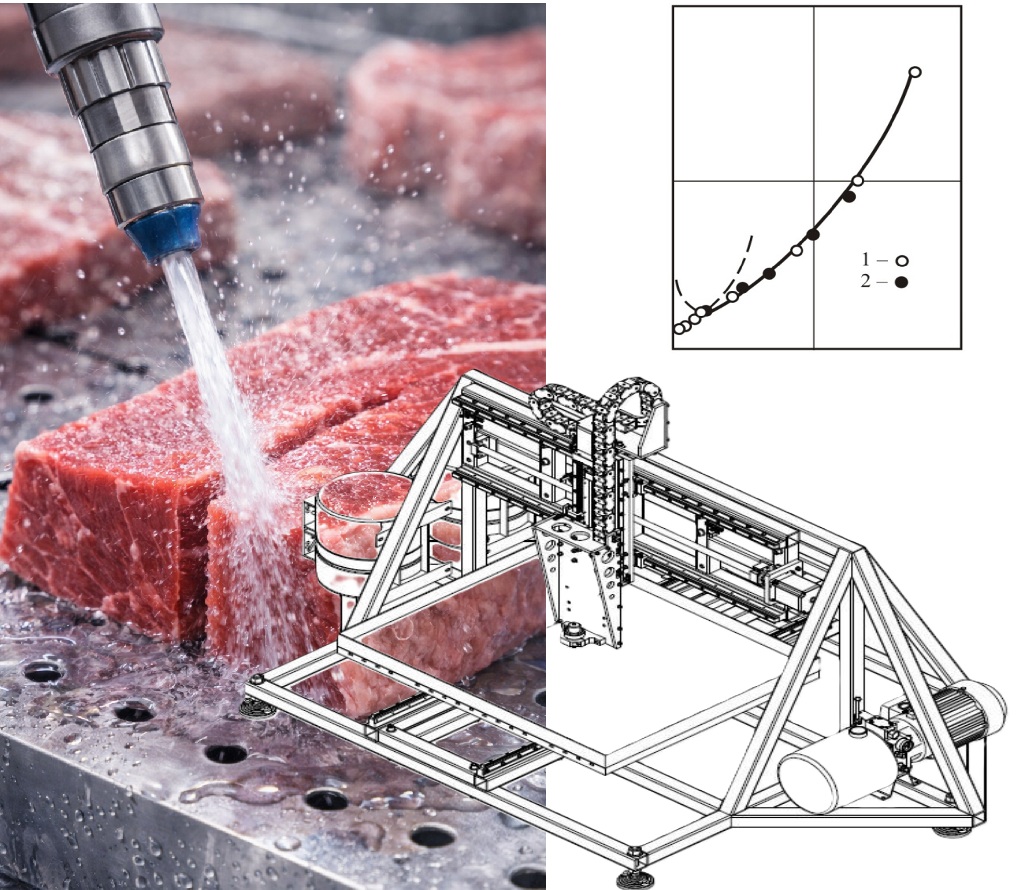

A scientifically grounded hydrodynamic calculation method for determining the optimal parameters of food product cutting using a water-polymer jet has been developed. This method is based on an established criterion that incorporates the relaxation time of the polymer solution and the longitudinal velocity gradient, which occurs during the flow of the polymer solution through the nozzle of the hydro-cutting head. An analytical expression for the relaxation time of the polymer solution has been derived, linking the experimentally observed relaxation time with the extrapolated relaxation time at zero concentration. The validity of this relationship, which connects the relaxation time of the polymer solution with its concentration, temperature, and characteristic viscosity, is confirmed by experimental data on the concentration dependence of the relaxation time for two fractions of polyethylene oxide in water.The developed method for calculating the optimal parameters of food cutting using a water-polymer jet enabled a significant reduction in the working pressure of the hydro-cutting machine – by 4 to 5 times – through the implementation of a high-efficiency cutting process. Under equal conditions, the cutting depth of frozen pork at –25 °С was increased by 2 to 2.3 times compared to water jet cutting, whereas standard equipment achieved only a 1.85 – fold increase. The experimental prototype of the hydro-cutting machine for food products using a water-polymer jet was 10 times less expensive than industrial-grade equipment. The developed method for calculating the optimal parameters for hydrojet water-polymer cutting has confirmed the practical feasibility and economic efficiency of using a water-polymer jet for cutting food products, particularly for deeply frozen products, by implementing a high-efficiency hydro-cutting process.

References

Cui, D., Li, H., He, J., Wang, Q., Lu, C., Hu, H., Cheng, X., Wang, C. (2022). Applications of water jet cutting technology in agricultural engineering: a review. Applied Sciences, 12(18), 8988, 1–18. doi: 10.3390/appl2188988

Xu, W., Wang, J., Deng, Y., Li, J., Yan, T., Zhao, S., Yang, X., Xu, E., Wang, W., Liu, D. (2022). Advanced cutting techniques for solid food: mechanisms, applications, modeling approaches and future perspectives. Materials Science, Comprehensive Reviews in Food Science and Food Safety, 21, 1568–1597. doi: 10.1111/1541- 4337.12896

Duspara, M., Starcevic, V., Samardzic, I. (2018). Preliminary communication analysis of zones created with water jet cutting of AISI 316 L corrosion resistant steel. Technical Gazette, 25, 2616–621. doi: 10.17559/TV-20170216095042

Gyliene, V. (2014). Investigation of abrasive water-jet cutting parameters influence on 6082 alluminium alloy surface roughness. Mechanika., 20(6), 602–606. doi: 10.5755/j01.mech.20.6.8865

Ranjan, P. Chaubey, P., Suresh, P., Vidya, S. (2022). Current research aspects and trends in abrasive water jet machining: a review. Advances in Mechanical Engineering and Technology, Springer: Singapore, 193–198. doi: 10.1007/978-981-16-9613-8_19

Liu, X., Liang, Z., Wen, G., Yuan, X. (2019). Water-jet machining and research developments: a review. International Journal of Advanced Manufacturing Technology, 102, 1257–1335. doi: 10.1007/s00170-018-3094-3

Natarajan, Y., Murugesan, P. K., Mohan, M., Liyakath Ali Khan, S. A. (2020). Abrasive water jet machining process: a state of art of review. Journal of Manufacturing Processes, 49, 271–322. doi: 10.1016/j.jmapro.2019.11.030

Perec, A., Tavodova, M. (2016). Abrasive water jet cutting depth optimization by taguchi approach. Manufacturing Technology, 16(3), 585–590. doi: 10.21062/ujep/x.2016/a/1213-2489/МТ/16/3/585

Wang, J., Shanmugam, D. K. (2009). Cutting meat with bone using an ultrahigh pressure abrasive water jet. Meat Science, 81(4), 671–677. doi: 10.1016/j.meatsci.2008.11.010

Pogrebnyak, A., Pogrebnyak, V, Perkun, I. (2020). Influence of geometric and dynamic parameters of a water-polymer jet on characteristics of food products hydro¬cutting process. Ukrainian Food Journal, 9(1), 197–208. doi: 10.24263/2304- 974X-2020-9-1-I7

Pogrebnyak, A., Pogrebnyak, V. (2017). Mechanism of the high efficiency of the cutting frozen food products using water-jet with polymer additions. Journal of food science and technoogy-ukraine, 11(2), 73–78. doi: 10.15673/fst.v11i2.517

Pogrebnyak, A., Chudyk, L, Pogrebnyak, V., Perkun, I. (2019). Coil-uncoiled chain transition of polyethylene oxide solutions under convergent flow. Chemistry and Chemical Technology, 13(4), 465–470. https://doi.org/10.23939/chchtl3.04.465

Pogrebnyak, V.G., Ivanyuta, Yu.F., Frenkel’, S.Ya. (1992). Structure of the hydrodynamic field and strain behavior of flexible macromolecules in convergent flow. Vysokomolekulyarnye Soedineniya, Ser. A, 34(3), 133–138.

D’iakova, N. E., Brestkin, Yu. V., Ahranova, S. F., Tverdokhleb, S. V. (1989), Birefringence effects of polymer-solutions in hydrodynamic fields. Vysokomolekulyarnye Soedineniya, Ser. B, 31(11), 844–846

Naumchik, N.V. (1995). On the hydrodynamic activity of polymers in high-velocity flows. Inzhenerno-Fizicheskii Zhurnal, 68(1), 146–148.

Povkh, I. L., Toryanik, A. I. (1979). Relation between molecular structure of polyethylene oxide and drag reduction. Journal of Engineering Physics, 37(4), 1131–1136. https://doi: 10.1007/BF00860980

Naumchuk, N. V., Tverdokhleb, S. V. (1992). Dynamic structurization in solutions of hydrodynamically active polymers. Journal of Engineering Physics and Thermophysics, 63(2), 763–765. doi: 10.1007/BF00861695

Pogrebnyak, A., Korneyev, M., Pogrebnyak, V., Yudina, O., Nebaba, N., Vishnikina, O. (2023). Intensification of water jet cutting process in deep-frozen food products. Ukrainian Food Journal, 12(3), 433–443. doi: 10.24263/2304-974X-2023-12-3-9

Pogrebnyak, A. V., Perkun, I. V., Pogrebnyak, V. G., Shimanskii, V. Y. (2021). Thermal Effects in the Flow of а Pоlуmеr Aqueous Solution Through a Hydrocutting Jet-Forming Head. Journal of Engineering Physics and Thermophysics, 94(1), pp. 137–142. DOI: 10.1007/s 10891-021-02281

Salyanov, V. I., Skuridin, S. G., Lortkipanidze, G. B., Chidzhavadze, Z. G., Toryanik A. I., Yevdokimov, Yu. M. (1978). Relation between molecular-structure of aqueous-solutions of polyethylene-glycol and compaction of double-stranded DNA-molecules. Molecular Biology, 12(3), 367–375.

Schowalter, W. R. (1978). Mechanics of non-Newtonian fluids. New York., Pergamon Press.

Ivanyuta, Yu. F., Naumchuk, N. V., Tverdokhleb, S. V., Frenkel’, S. Ya. (1985). Flow structure of aqueous solutions of polyethylene oxide in the inlet region of short capillaries. Journal of Engineering Physics, 49(4), 1192–1197. doi: 10.1007/BF00871917

Grosberg, A.I., KhokhlovA.R., (1994). Statistical physics of macromolecults. Maryland, American Inst. of Physics,

Mirau, P. A.; Jelinski, L. W. (2003). Macromolecules, Structure. Encyclopedia of Physical Science and Technology. New York, Academic Press, 857–901. https://doi.org/10.1016/B0-12-227410-5/00602-5

Zhang, Y., Cheng, D., Li, T., Guan,Y., Liu, B., Zhang, H., Dan Lu, D. (2023). Concentration effect on the chain structure and photoelectric properties of conjugated polymer precursor solutions and thin films: A mini review. J. polymer science, 62(6), 1156–1174. https://doi.org/10.1002/pol.20230803

Boyko, В. B., Insarova N. I. (1975), Flow of a viscous Newtonian medium in the plane of a hyperbolic cylinder and a single-sheet hyperboloid of revolution, Journal of Engineering Physics, 29(4), 675–681.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).