IMPROVED SINGLE-STAGE REFRIGERATION UNITS TO REPLACE TWO-STAGE UNITS

DOI:

https://doi.org/10.15421/jchemtech.v33i2.325344Keywords:

throttling, compression work, compressor volume and energy losses, refrigeration coefficient, thermal pollution of the atmosphereAbstract

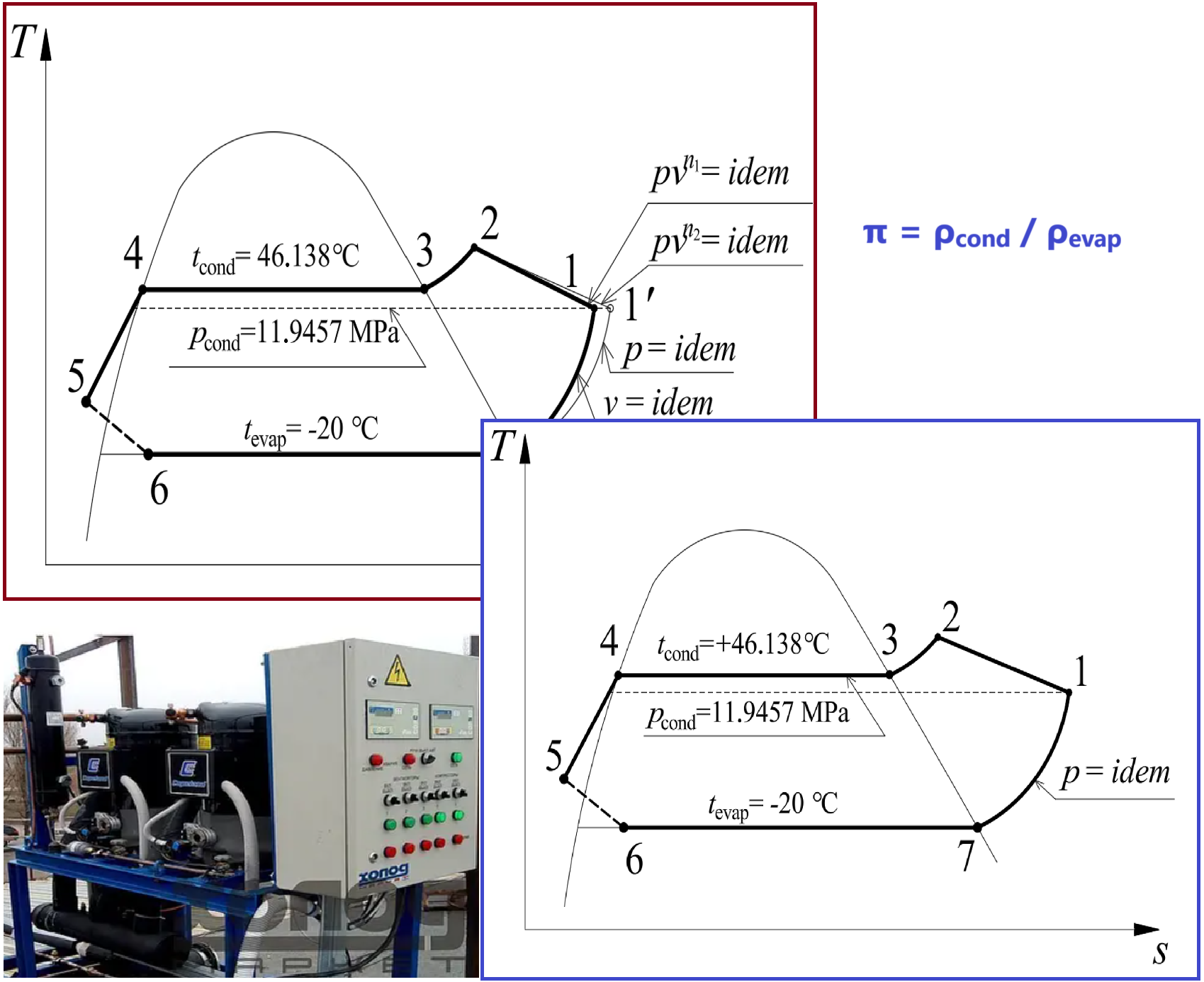

The ratio between the condensation pressure and the evaporation pressure of the working fluid in vapor-compressor refrigeration machines increases, the losses during throttling of the liquefied refrigerant and the work of adiabatic vapor compression increase. When this ratio π = ρcond / ρevap reaches a value of 8, to reduce the specified losses, they switch to a cycle with two-stage compression and intermediate vapor cooling and with double throttling of the liquefied refrigerant. However, such an improvement of vapor-compressor units complicates their operation. Therefore, in practice, single-stage refrigeration units are sometimes used even when π slightly exceeds the specified π value, and this leads to significant losses in the efficiency of the refrigeration cycle. The paper proposes to use improved single-stage refrigeration units as an alternative to two-stage refrigeration units. To verify the feasibility and effectiveness of this idea, a comparison of the efficiency indicators of two possible modifications of single-stage refrigeration units was performed to replace a two-stage one with a compression ratio π equal to 9. The calculations showed that the most effective substitute for two-stage refrigeration units is an improved single-stage unit with isochoric limit (maximum possible) regenerative superheating of steam and a polytropic process of its compression. Less effective, but more structurally simple, is a plant with isobaric superheating of steam. The reduction in the effective power of the compressors in these units relative to the indicator of a two-stage unit with limited regenerative heat exchange is 15 and 5 %, respectively, which means that the costs of electricity and fuel used for its generation are reduced. In addition, the thermal loads on the condensers of such plants are reduced, which means their weight and dimensions are reduced, and, most importantly, thermal pollution of the atmosphere is reduced (by 3 and 1 %, respectively).

References

Vasserman, O.A., Slynko, O.G. (2019). [Technical thermodynamics and heat transfer]. Odesa: Phoenix Publishing House. (in Ukranian).

Vasserman, O.A., Slynko, O.G., Shutenko M.A. (2020). [Innovative cycles of power plants]. Odesa: Phoenix Publishing House. (in Ukranian).

Vasserman, O.A., Slynko, O.G. (2022). [Refrigeration units and their innovation cycles]. monograph. Odesa, publishing house "Feniks". (in Ukranian).

Sleiti, A. K., Al-Khawaja, M., Al-Ammari, W. A. (2020). A combined thermo-mechanical refrigeration system with isobaric expander-compressor unit powered by low grade heat – Design and analysis. International Journal of Refrigeration, 120, 39–49 http://doi.org/10.1016/j.ijrefrig.2020.08.017

Wang, Z., Zhang, S., Xia, X., Zhao, Y., Yi, Q., Zhang, X. (2024). Experimental study on dynamic characteristics of organic Rankine cycle coupled vapor compression refrigeration system with a zeotropic mixture. Energy, 307, 132736 http://doi.org/10.1016/j.energy.2024.132736

Chandra, V. V., Ahmed, M. R. (2014). Experimental and computational studies on a steam jet refrigeration system with constant area and variable area ejectors. Energy Conversion and Management, 79, 377–386. http://doi.org/10.1016/j.enconman.2013.12.035

Kasaeian, A., Shamaeizadeh, A., Jamjoo, B. (2022). Combinations of Rankine with ejector refrigeration cycles: Recent progresses and outlook. Applied Thermal Engineering, 211, 118382. http://doi.org/10.1016/j.applthermaleng.2022.118382

Getie, M. Z., Lanzetta, F., Bégot, S., Admassu, B. T., Hassen, A. A. (2020). Reversed regenerative Stirling cycle machine for refrigeration application: A review. International Journal of Refrigeration, 118, 173–187. http://doi.org/10.1016/j.ijrefrig.2020.06.007

Redko, A., Redko, O., DiPippo, R. (2020). Principles and operation of refrigeration and heat pump systems. Low-Temperature Energy Systems with Applications of Renewable Energy, 1–45 http://doi.org/10.1016/b978-0-12-816249-1.00001-7

Slinko, A. G., Boychuk, A. S., Kozlovskyi, S. V. Lavrenchenko, G. K. (2024) Improvement of the thermodynamic cycle of single-stage steam compressor refrigerators. Journal of Chemistry and Technologies, 32(3), 806–814. https://doi.org/10.15421/jchemtech.v32i3.313076

Lemmon, E.W., Huber, M.L., McLinden, M.O. (2007). NIST Reference Fluid Thermodynamic and Transport Properties – REFPROP, Version 8.0. Gaithersburg.

Hu, Y., Badrawi, S. I., Kumar, J., Sabeh, H. N., Alsenani, T.R., Alkhalifah, F., Alkhalaf, T. Salem, A. F. (2023). Gas turbine-based system taking advantage of LNG regasification process for multigeneration purposes; Techno-economic-environmental analysis and machine learning optimization. Process Safety and Environmental Protection, 179, 10–26. http://doi.org/10.1016/j.psep.2023.08.068

Chen, Y.-M., Sun Ch.-Yu. (1997). Experimental study of the performance characteristics of a steam-ejector refrigeration system. Experimental Thermal and Fluid Science, 15(4), 384–394.

http://doi.org/10.1016/s0894-1777(97)00006-x

Colorado, D. Rivera, W. (2015). Performance comparison between a conventional vapor compression and compression-absorption single-stage and double-stage systems used for refrigeration. Applied Thermal Engineering, 87, 273–285. http://doi.org/10.1016/j.applthermaleng.2015.05.029

Coker, A. K. (2015). Chapter 17 - Refrigeration Systems. Ludwig's Applied Process Design for Chemical and Petrochemical Plants (Fourth Edition), 623–727. https://doi.org/10.1016/B978-0-08-094242-1.00017-6

Liu, J., Gao, Y., Lu; C., Ahmad, M. (2024). Enhancing energy and exergy performance of a cascaded refrigeration cycle: Optimization and comparative analysis. Journal of Cleaner Production, 438, 140760 http://doi.org/10.1016/j.jclepro.2024.140760

Colorado, D., Hernández, J.A., Rivera, W. (2012). Comparative study of a cascade cycle for simultaneous refrigeration and heating operating with ammonia, R134a, butane, propane and CO2 as working fluids, International Journal of Sustainable Energy, 31, 365–381. https://doi.org/10.1080/1478646X.2011.587012

Cimsit, C., Ozturk, I.T. (2012). Analysis of compression-absorption cascade refrigeration cycles, Applied Thermal Engineering, Vol: 40, Page: 311-317. https://doi.org/10.1016/j.applthermaleng.2012.02.035

Xu, Y., Shao, Zh., Tula, A. K. (2025). Integrated product and process design for cascade refrigeration. Computers & Chemical Engineering, 194, 108997 https://doi.org/10.1016/j.compchemeng.2025.108997

Pan, M., Zhao, H., Liang, D., Zhu, Y., Liang, Y., Bao G. (2020). A review of the cascade refrigeration system. Energies, 13, 2254 https://doi.org/10.3390/en13092254

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).