IMPACT OF BIOTECHNOLOGICAL FACTORS ON THE EFFICIENCY OF CORN MASH FERMENTATION IN THE PRODUCTION OF RECTIFIED ETHYL ALCOHOL

DOI:

https://doi.org/10.15421/jchemtech.v33i4.326705Keywords:

кукурудза; спиртові дріжджі; ферментні препарати; зародок; живлення; сухі речовини; сусло; зброджування; зріла бражка; леткі домішки.Abstract

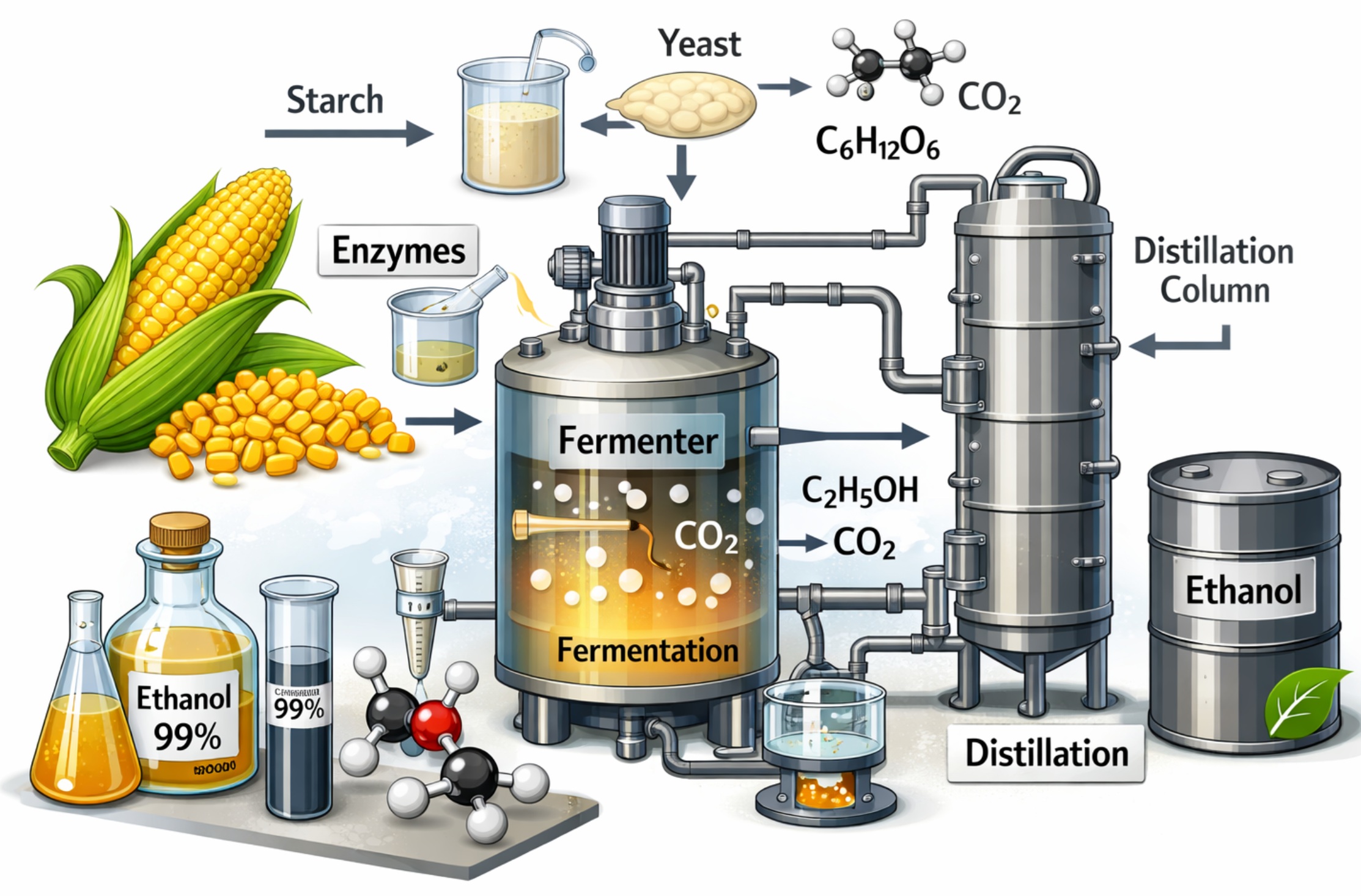

The article presents the results of studies on the influence of enzyme preparations, dry yeast, growth activators, and corn grain germs on the synthesis of ethanol and volatile impurities in the production of rectified ethyl alcohol. The research utilized enzyme preparations, dry distiller’s yeast, and activators supplied by leading domestic suppliers. It was established that as the solids content in the mash increased from 24 % to 28 %, the ethanol concentration in the fermentation mash rose by 13–22 % (from 12.4 % to 14.3 % v/v), reaching its highest level when using preparations from LLC “BIOTEST.” At the same time, the content of aldehydes, esters, and methanol in the experimental samples was the lowest. The minimum amount of aldehydes was formed in the fermentation mash with a solids content of 24 %, while the lowest concentration of fusel oils was observed in the wash obtained using preparations from LLC “A-PROFI.” The concentration of methyl alcohol was highest when using preparations from LLC “Novokontakt” and PE “KOUROS.” It was found that removing the grain germ before milling positively affects the qualitative composition of the fermentation mash. Processing raw materials with a lower content of ballast substances reduces the concentration of fusel oils, esters, and ethyl acetate in the fermentation mash, increases ethanol concentration by 7.7–8.9 %, and decreases methanol content by up to 40 %. Further processing of such wash in a distillation-rectification unit allows reducing energy consumption, lowering the production cost of rectified ethyl alcohol, and improving its quality indicators. The use of growth activators during yeast propagation increases ethanol concentration in the wash by 3.8 %, while the content of organic impurities rises insignificantly.

References

Babych, I., Boiko, P., Bondar, M., Kuts, A. (2022). Aspects of ethanol manufacture. Different purpose – different technological and economic solutions. Danish Scientific Journal, 60, 73–77.

Boiko, P. (2019). Technological and economic features of ethyl technical ethanol manufacture. Modern engineering and innovative technologies: International periodic scientific journal, 8(2), 39–42.

Ukrainets, A., Khomichak, L., Shyian, P., Oliinychuk, S. (2007). [Alcohol industry on the way to innovative development]. Kharchova i pererobna promyslovist, 12, 16–19 (in Ukrainian).

Balat, M., Balat, C. (2008). Progress in bioethanol processing. Progress in Energy and Combustion Science, 34(5), 551–573. doi:10.1016/ j.pecs.2007.11.001

Franceschin, G., Franceschin, G., Zamboni, A., Bezzo, F., Bertucco, A. (2008). Ethanol from corn: a technical and economical assessment based on different scenarios. Chemical Engineering Research and Design, 86(5), 488–498. doi:10.1016/j.cherd.2008.01.001.

[News Service. Bioethanol industry of Ukraine. Assessment and prospects]. (in Ukrainian). https://latifundist.com/analytics/30-bioetanol-stan-ta-otsinka-galuzi-v-ukrayini

Arslan, M., Tahir, H., Zareef, M., Shi, J., Allah, A., Bilal, M., Xiaowei, H., Zhihua, Li., Xiaobo, Z. (2021). Recent trends in quality control, discrimination and authentication of alcoholic beverages using nondestructive instrumental techniques. Trends in Food Science & Technology, 107, 80–113, https://doi.org/10.1016/j.tifs.2020.11.021.

Dewulf, J. (2002). Analysis of volatile organic compounds using gas chromatography. Trac-nrends in Analitical Chemistry, 21(9–10), 637–646. http://hdl.handle.net/1854/LU-158121.

Plutowska, B., Wardenski, W. (2008). Application of gas hromatography-olfactometry (GC-O) in analysis and quality assessment of alcoholic beverages – a review. Food Chemistry, 107, 449–463, https://doi.org/10.1016/j.foodchem.2007.08.058.

Oliynichuk, F.T., Danilova, K.O. (2023). Dextrinization of starch with alpha-amilase in the conditions of ethyl alcohol production. Journal of Chemistry and Technologies. 31(3), 627–634. https://doi.org/10.15421/jchemtech.v31i3.

Shyian, P. L., Sosnytskyi, V. V., Oliinichuk, S. T. (2009). [Innovative technologies of the alcohol industry. Theory and practice: a monograph]. Kyiv: Askaniia. (in Ukrainian).

Kosminska, O. S. (2021). [Improving the technology of alcohol from starch-containing raw materials with intensification of the processes of preparation of matured mash at the conditions of the Uladovsk distillery]. (Master's dissertation). (in Ukrainian),

Maicas, S. (2020). The Role of Yeasts in Fermentation Processes. Microorganisms, 8(8), 1142, https://doi.org/10.3390/microorganisms8081142.

Kovalchuk, S., Mudrak, Т., Nakonechna А. (2021). Study of quality of alcohol obtained by fermentation of highly concentrated grain wine by different races of yeast. Restaurant and hotel consulting. Innovations, 1(4), 158–168. https://doi.org/10.31866/2616-7468.4.1.2021.234836

Diaz-Hellin, P., Ubeda, J., Briones A. (2013). Improving alcoholic fermentation by activation of Saccharomyces species during the rehydration stage. LWT - Food Science and Technology, 50, 126–131.

Bonassa, G., Schneider, L., Cremonez, P., de Jesus de Oliveira, C., Teleken, J. G., Frigo, E. P. (2015). Optimization of first generation alcoholic fermentation process with Saccharomyces cerevisiae. Acta Scientiarum: Technology, Brazil, 37(3), 313–320, https://doi.org/10.4025.

Hua, X., Yang, R. (2015). Enzymes in starch processing. In book Enzymes in Food and Beverage Processing. Boca Raton. CRC Press. https://dx.doi.org/10.1201/b19408.

Bednarska, K. A. (2015). Kinetic modelling of enzymatic starch hydrolysis. Wageningen: Wageningen University. https://edepot.wur.nl/343988

Mohammed Salah, Khadija Marakchi, Najia Komiha and Maria Luisa Senent (2024). Theoretical Spectroscopic Study of Isopropyl Alcohol (CH3-CHOH-CH3), The Astrophysical Journal, 963(143), 12. https://doi.org/10.3847/1538-4357/ad1 fef.

Mishchenko, O. S., Oliinyk, S. I. (2023). [Implementation of the national standard for ethyl alcohol]. Naukovi pratsi DNU «UkrNDIspyrtbioprod»: «Biotekhnolohii prodovolchykh produktiv: problemy i perspektyvy», 46–51. (in Ukrainian).

Ponnampalam, E., Steele, D.B., Burgdorf, D. (2004). Effect of Germ and Fiber Removal on Production of Ethanol from Corn. (February 2004). Applied Biochemistry and Biotechnology, 113–116(1-3), 837–842. doi: 10.1385/ABAB:115:1-3:0837.

Ponnampalam, E., Steele, D. B., Burgdorf, D., McCalla, D. (2004). Effect of germ and fiber removal on production of ethanol from corn. Appl Biochem Biotechnol, 113-116, 837–42, doi: 10.1385/abab:115:1-3:0837.

Bulii, Y. V., Obodovych, O. M., Sydorenko, V. V. (2021). Increasing the degree of extraction organic impurities of rectified alcohol. Thermophysics and Thermal Power Engineering, 43(1), 68–74. https://doi.org/10.31472/ttpe.1.2021.8.

Bulii, Yu. V., Obodovych, O. M. (2019). [Energy-efficient bioethanol technology]. Enerhiia. Biznes. Komfort, Odesa: ONAKhT, 13–14. (in Ukrainian).

Shiyan, P., Mudrak, T., Kyrylenko, R., Kovalchuk, S. (2017). Effect of nitrogen and mineral composition of the high-concentrated wort made from starch-containing raw materials on the cultivation of yeast. Eastern–European Journal of Enterprise Technologies, 11, 72–77.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).