DEVELOPMENT OF A METHOD FOR PRODUCTION OF MEAT AND VEGETABLE PRESERVES WITH THE USE OF A LOW POWER ELECTRIC AUTOCLAVE

DOI:

https://doi.org/10.15421/jchemtech.v33i3.327294Keywords:

sterilization; process parameters; canned meat; nutritional and biological value; PLC; SCADA.Abstract

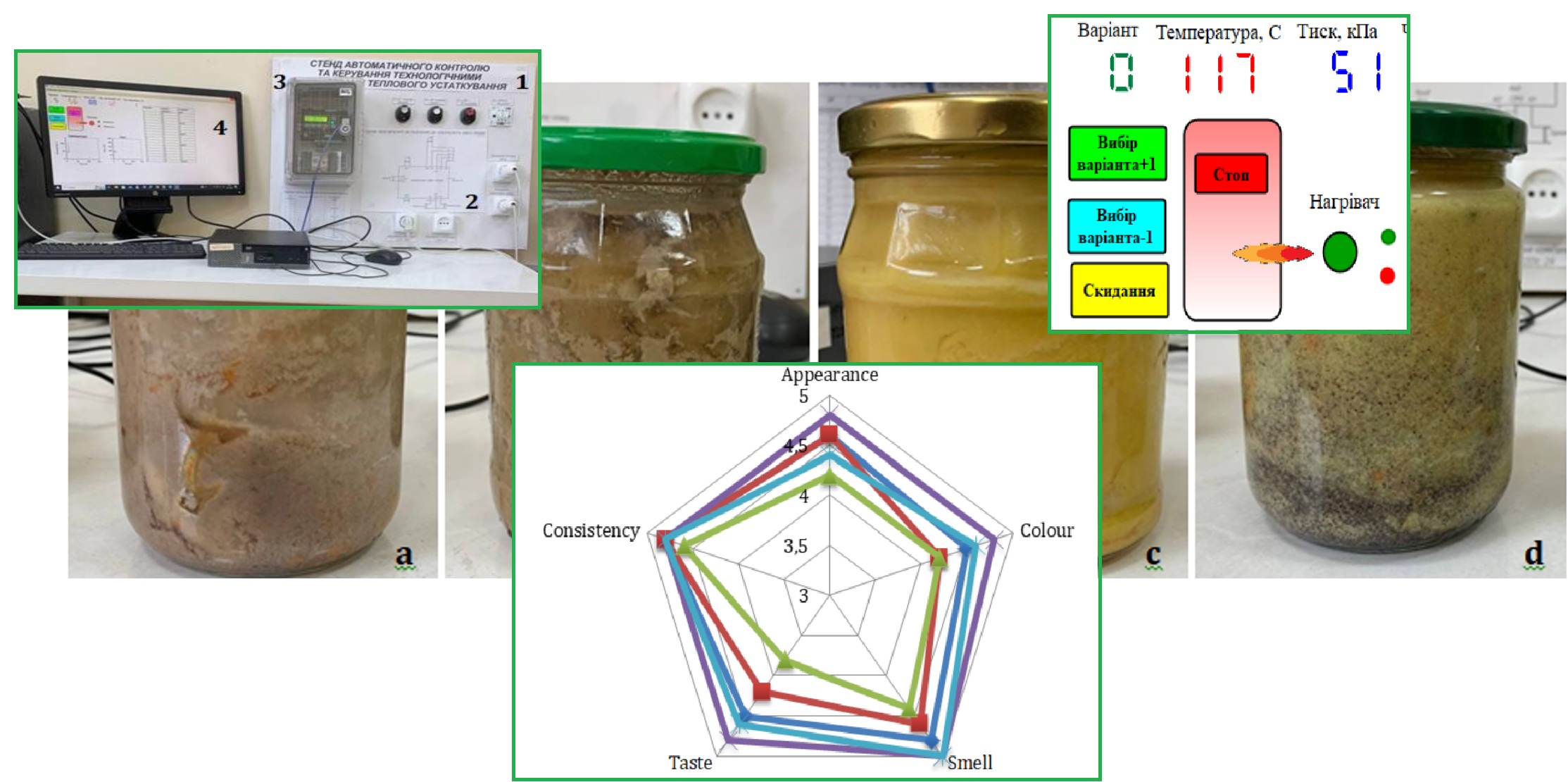

The article presents the results of the development of a method for producing meat and vegetable preserves using a test bench and a low-power electric autoclave at the laboratory of Sumy National Agrarian University. A Programmable Logic Controller (PLC) OWEN PR200 and a Supervisory Control and Data Acquisition (SCADA) system were used to regulate the technological parameters of sterilization. The main focus was placed on the development of recipes for meat and vegetable preserves enriched with plant-based ingredients: peanut flour, sunflower seed meal, white lupine flour, and rape seed meal. Sterilization was conducted at 110 °C for 20 minutes according to a predefined program. Sensory evaluation, based on a five-point expert panel scale, revealed improvements in taste, aroma, texture, and color in samples with plant-based additives. The highest sensory scores were observed in samples containing white lupine flour and rape seed meal. Nutritional value analysis revealed that the inclusion of plant materials enriched the preserves with proteins and fats, leading to increased levels of essential amino acids and fatty acids. The most significant increases were observed in Sample No. 1, with peanut flour (21.7 ± 0.7 %) and Sample No. 2, with sunflower seed meal (21.4 ± 0.6 %), highlighting the positive impact of peanut flour and sunflower seed meal. The control Sample No. 0 had a fat content of 6.5 ± 0.1 %, whereas all experimental samples had lower fat content, ranging from 2.7 ± 0.2 % to 3.4 ± 0.2 %. The article provides a detailed description of the technological stages in the production process, including raw material preparation, sterilization, parameter control, and the application of automated bench. The results demonstrate the potential of the developed method for producing high-quality meat and vegetable preserves.

References

Bal-Prylypko, L., Nikolayenko, M., Danylenko, S., Ustymenko, I., Medvediev, Y., Ryabovol, M. (2023). Optimization of amino acid composition of albumens of canned ham. Food Resources, 11(21), 44–52. (in Ukrainian). doi:10.31073/foodresources2023-21-04

Vlasenko, I., Semko, T., Ivanishcheva, O. (2021). Functioning analysis of meat processing industry in modern conditions on the example of Ukraine. Technology audit and production reserves, 2(4(58)), 12–15. doi:10.15587/2706-5448.2021.229693

Johnson, M., Clark, S. (2021). Ethical Challenges in Automated Livestock Management. Journal of Agricultural Ethics, 35(2), 158–172.

de Oliveira, A. S., dos Santos, B. A., Farias, C. A. A., Correa, L. P., Cordeiro, M. W. S., Pinton, M. B., Barcia, M. T., Wagner, R., Cichoski, A. J., Barin, J. S. (2023). Pea Protein Isolate as a Meat Substitute in Canned Pork Pâté: Nutritional, Technological, Oxidative, and Sensory Properties. Foods, 12(18), 3486. doi:10.3390/foods12183486

Thakur, S., Pandey, A. K., Verma, K., Shrivastava, A., Singh, N. (2024). Plant-Based Protein as an Alternative to Animal Proteins: A Review of Sources, Extraction Methods and Applications. International Journal of Food Science & Technology, 59(1), 488–497. doi:10.1111/ijfs.16663

Cutroneo, S., Prandi, B., Pellegrini, N., Sforza, S., & Tedeschi, T. (2024). Assessment of Protein Quality and Digestibility in Plant-Based Meat Analogues. Journal of Agricultural and Food Chemistry, 72(14), 8114–8125. doi:10.1021/acs.jafc.3c08956

Munialo, C. D. (2024). A Review of Alternative Plant Protein Sources, Their Extraction, Functional Characterisation, Application, Nutritional Value and Pinch Points to Being the Solution to Sustainable Food Production. International Journal of Food Science & Technology, 59(1), 462–472. doi:10.1111/ijfs.16467

Nedumaran, Dr., Ritha, M. (2024). Robotics revolution: transforming the food industry through automation and innovation. SSRN Electronic Journal. 2, 165–170. doi:10.2139/ssrn.4758029.

Chandrasiri, G.S.M., Wijenayake, A.K.I. Udara, S.P.R. (2022). Development of automated systems for the implementation of food processing. J. Res. Technol. Eng., 3(1), 8–18.

Sabadash, S., Savchenko-Pererva, M., Radchuk, O., Rozhkova, L., Zahorulko, A. (2020). Improvement of equipment to intensify the drying process of dispersed food products. Eastern-European Journal of Enterprise Technologies, 11(103), 15–21, doi:10.15587/1729-4061.2020.192363.

Savchenko-Pererva, M., Yakuba, O. (2015). Improving the efficiency of devices with counter-twisting flows for the food. Eastern-European Journal of Enterprise Technologies, 8(122), 44–52, doi:10.15587/1729-4061.2023.277896.

Sukmanov, V.A., Radchuk, O.V., Savchenko-Pererva, M.Y., Budnik, N.V. (2020). Optical piezometer and precision researches of food properties at pressures from 0 to 1000 MPa. Journal of Chemistry and Technologies, 28, 68–87.

https://doi.org/10.15421/082009

Barsukova, H. V., Savchenko-Pererva M. Y. (2020). [Reducing the technogenic load on the environment due to the technical solution for the disposal of iron sulphate]. Journal of Chemistry and Technologies, 28(2), 168–176 (in Ukrainian). http://doi.org/ 10.15421/082018

Galeazzi, G., Krishnan, P., Masi, G. (2020). Application of AI-based Quality Control Systems in Food Manufacturing: A Case Study. Journal of Food Engineering, 282, 110030. https://doi.org/10.1016/j.jfoodeng.2020.110030

Chandrasiri, G.S.M., Wijenayake, A.K.I. Udara, S.P.R. (2022). Development of automated systems for the implementation of food processing. J. Res. Technol. Eng., 3(1), 8–18.

Savchenko, M., Radchuk, O. Gerasimenko, V., Chepizhnyi, A. (2024). Development of a methodology for calculating the consumption of a combined renewable energy source for a mini–workshop. IOP Conference Series: Earth and Environmental Science, 1429(1), 012018. doi:10.1088/1755-1315/1429/1/012018

Li, X., Shen, Y., Hu, F., Zhang, X., Thakur, K., Rengasamy, K., Rizwan, M., Busquets, R., Wei Z. (2023). Fortification of polysaccharide-based packaging films and coatings with essential oils: A review of their preparation and use in meat preservation. International Journal of Biological Macromolecules, 242(1), 124767. https://doi.org/10.1016/j.ijbiomac.2023.124767

Feknous, I., Saada, D., Boulahlib, C., Alessandroni, L., Souidi, S., Chabane, O., Gagaoua, M. (2023). Poultry meat quality preservation by plant extracts: an overview. Scientific Journal "Meat Technology", 64(3), 80–101. https://doi.org/10.18485/meattech.2023.64.3.2

Ulloa-Saavedra, A., Garcіa-Betanzos, C., Zambrano-Zaragoza, M., Quintanar-Guerrero, D., Mendoza-Elvira, S., Velasco-Bejarano, B. (2022). Recent Developments and Applications of Nanosystems in the Preservation of Meat and Meat Products. Foods, 11(14), 2150. doi:10.3390/foods11142150

Rahman, M., Hashem, M., Azad, M., Choudhury, M., Bhuiyan, M. (2023). Techniques of meat preservation- A review. Meat Research, 3(3). https://doi.org/10.55002/mr.3.3.55

Bariya, А., Rathod, N., Patel, А., Nayak, J., Ranveer, R., Hashem, А., Abd-Allah, Е., Ozogul, F., Jambrak, А., Rocha, J. (2023). Recent developments in ultrasound approach for preservation of animal origin foods. Ultrasonics Sonochemistry, 101, 106676. https://doi.org/10.1016/j.ultsonch.2023.106676

Inguglia, E. S., Granato, D., Kerry, J. P., Tiwari, B. K., Burgess, C. M. (2021). Ultrasound for Meat Processing: Effects of Salt Reduction and Storage on Meat Quality Parameters. Applied Sciences, 11(1), 117. https://doi.org/10.3390/app11010117

Royintarat, T., Choi, Е., Boonyawan, D., Seesuriyachan, Р., Wattanutchariya, W. (2020). Chemical-free and synergistic interaction of ultrasound combined with plasma-activated water (PAW) to enhance microbial inactivation in chicken meat and skin. Scientific Reports, 10, 1559. https://doi.org/10.1038/s41598-020-58199-w

Joo, H., Mizan, M. F. R., Hossain, M. I., Lee, D., Ha, S. (2020). Enhanced elimination of Salmonella Typhimurium and Campylobacter jejuni on chicken skin by sequential exposure to ultrasound and peroxyacetic acid. Journal of Food Safety, 40(4), е12803. https://doi.org/10.1111/jfs.12803

Khalilov? F. V. (2021). Automation of the sterilization process of canned products in the Master SCADA system. Galaxy International Interdisciplinary Research Journal, 9(12), 659–662.

Tomar, B., Kumar, N., Sreejeth, M. (2024). PLC and SCADA based temperature control of heat exchanger system through fractional order PID controller using metaheuristic optimization techniques. Heat Mass Transfer, 60, 1585–1602.

https://doi.org/10.1007/s00231-024-03509-5

Tomar, B., Kumar, N. (2020). PLC and SCADA based industrial automated system. IEEE Int. Conf. for Innovation in Technology (INOCON), 1–5.

Kaichenov, A., Vlasov, A., Maslov, A., Selyakov, I., Glukhykh, Yu. (2020). [Development of a model of thermal processes of an autoclave for a simulator of the process of sterilization of canned food]. KnE Life Sciences, 5(1), 437–449 (in Ukrainian).

Pullaiah, D., Sekaran, S., Alexander, T., Krishnamoorthy, N. R. (2021). Development of PLC Program for Multi-Process Parameter and Multi Profile-based Control Logic for Heat Treatment Industrial Applications. Journal of Physics: Conference Series, 1770, 012038. https://doi.org/10.1088/1742-6596/1770/1/012038

Makowska, A., Zielinska-Dawidziak, M., Waszkowiak, K., Myszka, K. (2023). Effect of Flax Cake and Lupine Flour Addition on the Physicochemical, Sensory Properties, and Composition of Wheat Bread. Applied Sciences, 13(13), 7840. https://doi.org/10.3390/app13137840

Guardianelli, L. M., Carbas, B., Brites, C., Puppo, M. C., & Salinas, M. V. (2023). White Lupine (Lupinus albus L.) Flours for Healthy Wheat Breads: Rheological Properties of Dough and the Bread Quality. Foods, 12(8), 1645.

https://doi.org/10.3390/foods12081645

Di Lena, G., Sanchez del Pulgar, J., Lucarini, M., Durazzo, A., Ondrejickova, P., Oancea, F., Frincu, R.-M., Aguzzi, A., Ferrari Nicoli, S., Casini, I., Gabrielli, P., Caproni, R., Cerven, I., Lombardi-Boccia, G. (2021). Valorization Potentials of Rape seed Meal in a Biorefinery Perspective: Focus on Nutritional and Bioactive Components. Molecules, 26(22), 6787.

https://doi.org/10.3390/molecules26226787

Yahbi, M., Keli, A., El Alami, N., Nabloussi, A., Maataoui, A., Daoui, K. (2024). Chemical composition and quality of rape seed meal as affected by genotype and nitrogen fertilization. OCL, 31(5). https://doi.org/10.1051/ocl/2024004

Kasprowicz-Potocka, M., Zaworska-Zakrzewska, A., Lodyga, D., Jozefiak, D. (2024). The Effect of Enzymatic Fermentation on the Chemical Composition and Contents of Antinutrients in Rape seed Meal. Fermentation, 10(2), 107.

https://doi.org/10.3390/fermentation10020107

Idrissi, Z., Oubihi, A., Ibourki, M., Youssfi, M., Gharby, S., Guezzane, C., Ullah, R., Iqbal, Z., Goh, K., Gallo, M., Bouyahya, A., Harhar, H., Tabyaoui, M. (2024). Peanut (Arachis hypogaea L.) flour and oilcake flour: Exploring the influence of roasting and varietal differences on proximal composition, elemental profiling, antimicrobial and antioxidant properties. Food Chemistry: X, 24, 101791.

https://doi.org/10.1016/j.fochx.2024.101791

Shongwe, S., Kidane, S., Shelembe, J., Nkambule, T. (2022). Dough rheology and physicochemical and sensory properties of wheat–peanut composite flour bread. Legume Science, 4(3), е138.

https://doi.org/10.1002/leg3.138

Singh, A., Raina, S., Sharma, M., Chaudhary, M., Sharma, S., Rajpal, V. (2021). Functional Uses of Peanut (Arachis hypogaea L.) Seed Storage Proteins. Grain and Seed Proteins Functionality, 121-142.

http://dx.doi.org/10.5772/intechopen.96871

Petraru, A., Ursachi, F., Amariei, S. (2021). Nutritional Characteristics Assessment of Sunflower Seeds, Oil and Cake. Perspective of Using Sunflower Oilcakes as a Functional Ingredient. Plants, 10(11), 2487.

https://doi.org/10.3390/plants10112487

Sumon, M. M., Ahmed, K. U., Nuruddin, M. M., Hossain, A., Hussain, M. A. (2020). Comparative Study on Physicochemical Composition of Different Genotypes of Sunflower Seed and Mineral Profile of Oil Cake. The Agriculturists, 18(2), 83-93.

https://doi.org/10.3329/agric.v18i2.51062

Li, Z., Xiang, F., Huang, X., Liang, M., Ma, S., Gafurov, K., Gu, F., Guo, Q., Wang, Q. (2024). Properties and Characterization of Sunflower Seeds from Different Varieties of Edible and Oil Sunflower Seeds. Foods, 13(8), 1188.

https://doi.org/10.3390/foods13081188

Thepthanee, C., Li, H., Wei, H., Prakitchaiwattana, C., Siriamornpun, S. (2024). Effect of Soaking, Germination, and Roasting on Phenolic Composition, Antioxidant Activities, and Fatty Acid Profile of Sunflower (Helianthus annuus L.) Seeds. Horticulturae, 10(4), 387.

https://doi.org/10.3390/horticulturae10040387

Radchuk, O., Savchenko, M., Sokolov, S., Sokolov, O. (2025). Automation of a laboratory electric autoclave using a programmable logic controller. Journal of Chemistry and Technologies, 33(1), 239–248.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).