STUDY OF BENEFICIATION WASTE PROCESSING IRON ORE

DOI:

https://doi.org/10.15421/jchemtech.v33i2.328767Keywords:

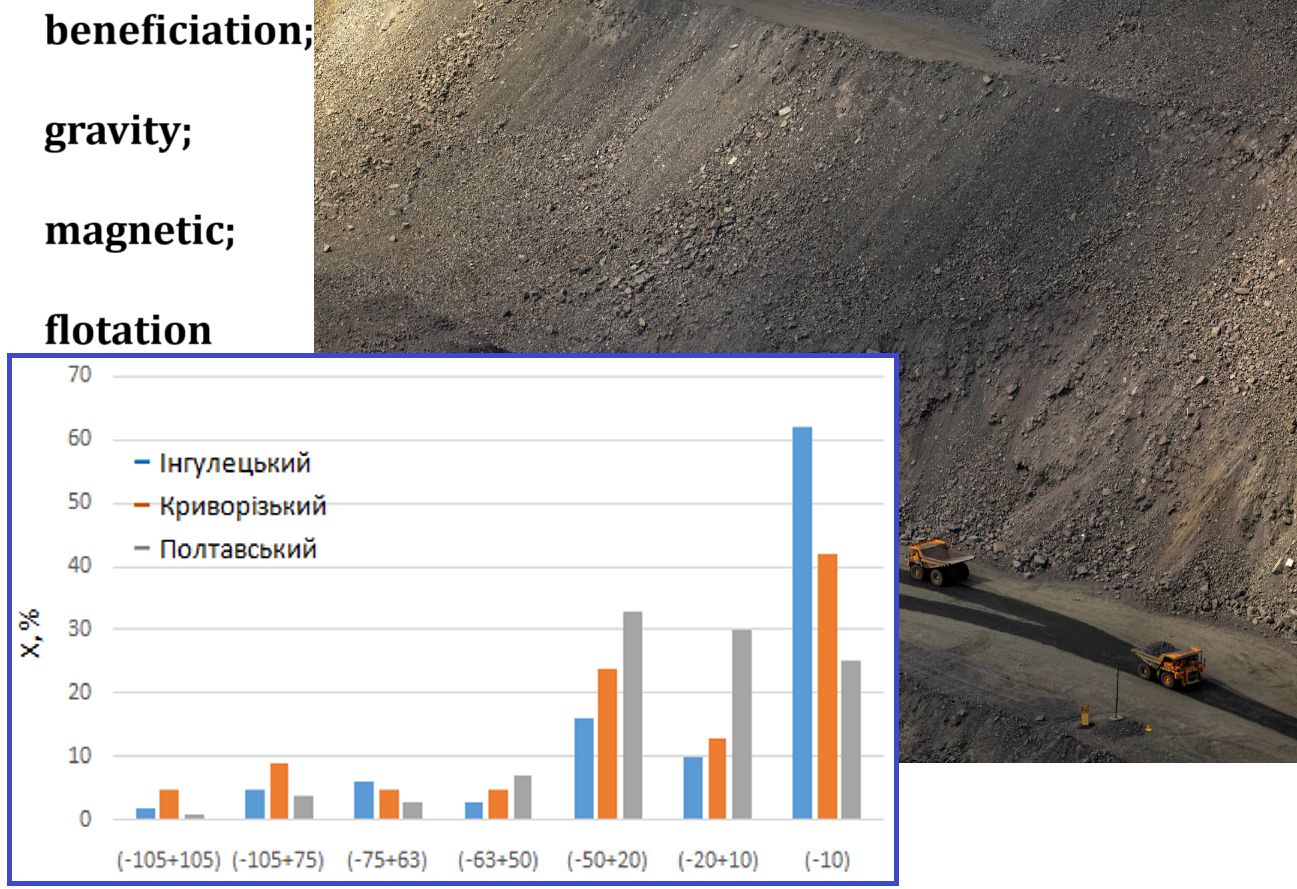

Keywords: iron ore, waste, iron, alumina, silica, beneficiation, gravity, magnetic, flotation, processingAbstract

This paper reviews studies on the processing of iron ore concentration wastes from several samples of Ukrainian ore processing plants. The morphological and chemical composition of the Kryvyi Rih, Ingulets, and Poltava samples was determined. A basic technological scheme for processing these samples is presented. It was found that the Kryvyi Rih waste sample contains 38 % total iron, 20 % silica, and 14 % alumina, while the Inhulets sample contains almost 50 % total iron, 10 % silica, and 8 % alumina, while the Poltava sample contains only 28 % iron, 55 % silica, and 2 % alumina. The effect of gravity beneficiation is most effectively reflected in the Poltava sample, as a result of an increase in Fe content from 28 % to 52 %. It was found that the subsequent magnetic beneficiation of the Poltava sample increases the Fe content from 52 % to 63 %, with a mass yield of 65 %. It was found that the final stage – flotation beneficiation of the Poltava sample increases the Fe content from 63 % to almost 66 %, which makes it possible to use it further.

References

Zhang, X., Han, Y., Sun, Y., Lv, Y., Li, Y., Tang, Z. (2019). A Novel Method for Iron Recovery from Iron Ore Tailings with Pre-Concentration Followed by Magnetization Roasting and Magnetic Separation. Mineral Processing and Extractive Metallurgy Review, 41(2), 117–129. https://doi.org/10.1080/08827508.2019.1604522

Zhao, S., Fan, J., Sun, W. (2014). Utilization of iron ore tailings as fine aggregate in ultra-high performance concrete. Construction and Building Materials, 50, 540–548. doi:10.1016/j.conbuildmat.2013.10.019

Khlopytskyi, A., Savenkov, A., Bliznjuk, O., Skiba, M., Vorobiova, V., Masalitina, N. (2022). Leaching of FeO and CaO by nitric acid from ash-slag wastes of thermal power plants.Voprosykhimiiikhimicheskoitekhnologii, 1, 95–99. DOI: 10.32434/0321-4095-2022-140-1-95-99

Klymova, N., Khlopytskyi, O., Kovalenko, I., Makarchenko, N. (2024). Research on the extraction of rare earth elements from ash-slag waste. Voprosy Khimii i Khimicheskoi Tekhnologii, 2, 26–31. doi: 10.32434/0321-4095-2024-153-2-26-31

Khlopytskyi, O.O., Kovalenko, I.L., Frolova, L.A., Skiba, M.I., Makarchenko, N.P. (2023). Ash and slag waste of thermal power plants as a promising raw material of the present. Journal of Chemistry and Technologies, 31(3), 635–641. https://doi.org/10.15421/jchemtech.v31i3.286130

Gunarathne, V., Rajapaksha, A. U., Vithanage, M., Alessi, D. S., Selvasembian, R., Naushad, Mu., Ok, Y. S. (2020). Hydrometallurgical processes for heavy metals recovery from industrial sludges. Critical Reviews in Environmental Science and Technology, 52(6), 1022–1062. https://doi.org/10.1080/10643389.2020.1847949

Frolova, L.A., Pivovarov, A.A., Butyrina, T.E. (2015). Purification of wastewaters, containing chromium, by a sorbent based on blast furnace slag. J. Water Chem. Technol. 37, 185–190. https://doi.org/10.3103/S1063455X15040062

Frolova, L., Khlopytskyi, O., Kashkalda, N., Ivanchenko, H. (2023). IOP Conf. Ser.: Earth Environ. Sci., 1156(1), 012032. doi 10.1088/1755-1315/1156/1/012032

Sumukh, E. P., Das, B. B.,Barbhuiya, S. (2024). Effect of Iron Ore and Copper Ore Tailings on Engineering Properties and Hydration Products of Sustainable Cement Mortar. Advances in Civil Engineering Materials. 13(1), 50–75. https://doi.org/10.1520/ACEM20230031

Koltsova, Y.I., Nikitin, S.V. (2020). Preparation of porous glass-ceramic materials by using fuel slag. Voprosy Khimii i Khimicheskoi Tekhnologii, 1, 33–38. DOI: 10.32434/0321-4095-2020-128-1-33-38

Koltsova, Y.I. (2021). Influence of sodium salt additives on the properties of coatings containing industrial waste. Journal of Chemistry and Technologies, 29(1), 100–106. https://doi.org/10.15421/082105

Shchukina, L., Galushka, Ya., Khlopytskyi, A., Savenkov, A. (2020). Prospects of the application of coal ash materials to produce construction heat-insulation ceramics. Voprosy khimii i khimicheskoi tekhnologii, 4, 215–224, DOI: 10.32434/0321-4095-2020-130-3-215-224

Schatzmayr, Th., Sá, W., Sandra, O., Karla, V., Branco, C., Machado Balthar, L., Dias, R., Filho, T. (2022). Use of iron ore tailings and sediments on pavement structure. Construction and Building Materials, 342(B), 128072. https://doi.org/10.1016/j.conbuildmat.2022.128072

Bliznjuk, O.N., Masalitina, N.Yu., Savenkov, A.S., Suvorin, A.V., Khlopytskyi, A.A. (2019). Synthesis of a multioxide catalyst for the oxidation of ammonia to nitrogen(II) oxide. Voprosy khimii i khimicheskoi tekhnologii, 3, 98–118. doi: 10.32434/0321-4095-2019-124-3-98-108

Han, X., Wang, F., Zhao, Y., Meng, J. (2023). Recycling of iron ore tailings into magnetic nanoparticles and nanoporous materials for the remediation of water, air and soil: a review. Environ Chem Lett 21, 1005–1028. https://doi.org/10.1007/s10311-022-01541-7

Pollmann, K., Kutschke, S., Matys, S., Kostudis, S., Hopfe, S., Raff, J. (2016). Novel Biotechnological Approaches for the Recovery of Metals from Primary and Secondary Resources. Minerals, 6(2), 54. https://doi.org/10.3390/min6020054

Vitor, O., Silvestro, L., Gleize, Ph., Kirchheim, A., Schneider, I. (2023). Application of leached iron ore tailings to produce sustainable cements. Construction and Building Materials, 377, 131095. https://doi.org/10.1016/j.conbuildmat.2023.131095

Bulayani, M.M., Raghupatruni, P., Mamvura, T., Danha, G. (2024). Exploring Low-Grade Iron Ore Beneficiation Techniques: A Comprehensive Review. Minerals, 14(8), 796. https://doi.org/10.3390/min14080796

Chokin, K., Yedilbayev, A., Yugai, V., Medvedev, A. (2022). Beneficiation of Magnetically Separated Iron-Containing Ore Waste. Processes, 10(11), 2212. https://doi.org/10.3390/pr10112212

Zare, A., Noaparast, M., Dehghan, S. (2023). Recovery of Iron Ore From The Tailings of Tang Zagh Iron Beneficiation Plant: A Comparative Study of Gravity and Magnetic Separation Methods. Journal of Geomine, 1(3), 137–143.doi:10.22077/JGM.2024.7407.1025

Yu, J. Han, Yu. Li, Ya. Gao, P. (2017). Beneficiation of an iron ore fines by magnetization roasting and magnetic separation. International Journal of Mineral Processing, 168, 102–108. https://doi.org/10.1016/j.minpro.2017.09.012

Dudchenko, N., Ponomar, V., Ovsiienko, V., Cherevko, Y., Perelshtein, I. (2023). Mineral magnetic modification of fine iron ore tailings and their beneficiation in alternating magnetic fields. Metals, 14(1), 26. https://doi.org/10.3390/met14010026

Zhang, X., Gu, X., Han, Y., Parra-Alvarez, N., Claremboux, V., Kawatra, S. K. (2019). Flotation of iron ores: A review. Mineral Processing and Extractive Metallurgy Review, 42(3), 184–212.http://doi.org/10.1080/08827508.2019.1689494

Nakhaei, F., Irannajad, M. (2018). Reagents types in flotation of iron oxide minerals: A review. Mineral processing and extractive metallurgy review, 39(2), 89–124. https://doi.org/10.1080/08827508.2017.1391245

Jyotirmoy, S., Rajkhowa, S., Mahiuddin, S. (2022). Upgradation of Iron Ore Fines and Slime by Selective Flocculation Using Surface‐Active Agents, Settling Study, and Characterization of the Beneficiation Waste for Value Addition. Journal of Chemistry, 2022(1), 6451187. DOI:10.1155/2022/6451187

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).