ANALYSIS OF MODERN METHODS OF LEGUME PROCESSING AND THEIR IMPACT ON THE NUTRITIONAL VALUE AND DIGESTIBILITY OF RAW MATERIALS

DOI:

https://doi.org/10.15421/jchemtech.v33i4.331093Keywords:

legumes, processing, nutritional value, bioavailability, fermentation, ultrasound, high pressure, extrusion, electromagnetic fields, infrared heating, microwave processing, functional properties, organoleptic properties, food safetyAbstract

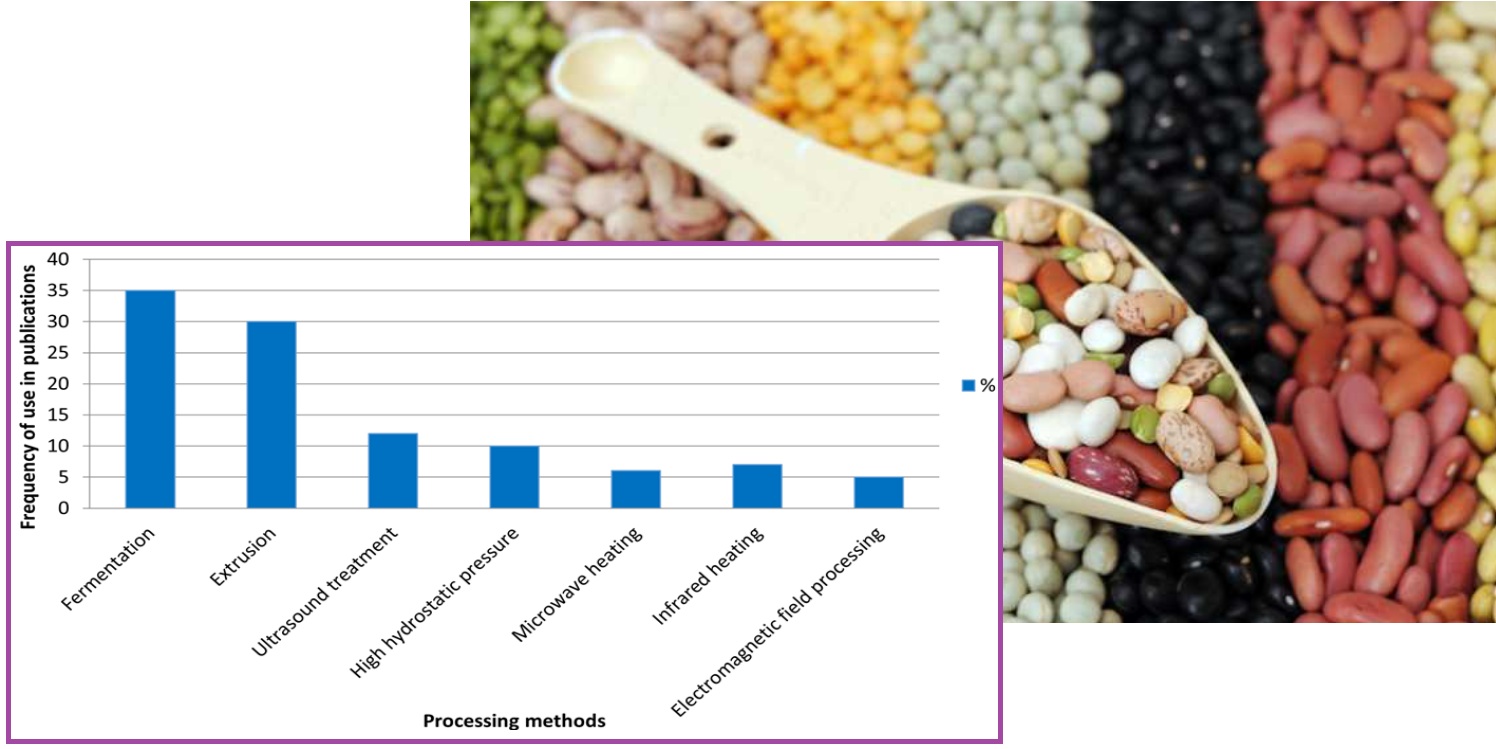

This review article systematically analyzes and synthesizes current scientific literature on modern innovative methods of legume processing and their impact on nutritional value, functional properties, and sensory characteristics of final products. Key technologies, including fermentation, ultrasonic processing, high-pressure processing, extrusion, microwave and infrared heating, and electromagnetic field treatment, are critically reviewed and compared. Particular attention is focused on synthesizing reported data on the reduction of anti-nutrients, increasing the bioavailability of proteins and trace elements, and improving the texture and taste of legume-based products. This review analyzes the scientific basis and technological principles of each method and highlights literature-reported mechanisms through which they affect the structural and chemical composition of pulses. The synergistic effects of combined processing methods are discussed in the context of improved nutrient retention, reduced energy consumption, and enhanced processing efficiency. The synthesis of the literature indicates that these methods contribute to expanding the use of pulses in the food industry, particularly in the production of high-protein snacks, meat and dairy alternatives, gluten-free products, and functional foods with targeted health benefits. These technologies support sustainable and innovative food systems by increasing the value of pulses as affordable and environmentally friendly protein sources. In addition, special attention is dedicated to integrated processing approaches that combine several advanced methods to achieve high efficiency in improving the nutritional, physicochemical, and sensory properties of pulses. This review identifies the importance of process optimization, scaling-up potential, and the impact of processing conditions on product quality and consumer acceptance. The findings of this review can be used to develop novel food products, optimize production processes, increase supply chain sustainability, and guide further research in plant-based processing technologies. This review emphasizes the strategic role of pulses in supporting global food security and the transition to healthier and more sustainable diets.

References

. Jimenez-Lopez, J. C., Singh, K. B., Clemente, A., Nelson, M. N., Ochatt, S., Smith, P. M. C. (2020). Editorial: Legumes for Global Food Security. Frontiers in Plant Science, 11. https://doi.org/10.3389/fpls.2020.00926

. Gore, N. T., Shaikh, S. S., Sule, V. A., Umdale, S. D., Mundada, P. S., Gaikwad, N. B., Ahire, M. L. (2024). Understanding the nutritional profile of Vigna trilobata: A lesser-known, underexplored grain legume. Food and Humanity, 3, 100343. https://doi.org/10.1016/j.foohum.2024.100343

. Neji, C., Semwal, J., Kamani, M. H., Máthé, E., Sipos, P. (2022). Legume protein extracts: The relevance of physical processing in the context of structural, techno-functional and nutritional aspects of food development. Processes, 10(12), 2586. https://doi.org/10.3390/pr1012586

. Semba, R. D., Ramsing, R., Rahman, N., Kraemer, K., Bloem, M. W. (2021). Legumes as a sustainable source of protein in human diets. Global Food Security, 28, 100520. https://doi.org/10.1016/j.gfs.2021.100520

. Vasconcelos, M. W., Grusak, M. A., Pinto, E., Gomes, A., Ferreira, H., Balázs, B., Centofanti, T., Ntatsi, G., Savvas, D., Karkanis, A., Williams, M., Vandenberg, A., Toma, L., Shrestha, S., Akaichi, F., Barrios, C. O., Gruber, S., James, E. K., Maluk, M., Karley, A., Iannetta, P. (2020). The biology of legumes and their agronomic, economic, and social impact. In Springer eBooks. https://doi.org/10.1007/978-981-15-4752-2_1

. Carcea, M. (2020). Nutritional value of Grain-Based foods. Foods, 9(4), 504. https://doi.org/10.3390/foods9040504

. Carbas, B., Machado, N., Pathania, S., Brites, C., Rosa, E. A., Barros, A. I. (2021). Potential of legumes: nutritional value, bioactive properties, innovative food products, and application of eco-friendly tools for their assessment. Food Reviews International, 39(1), 160–188. https://doi.org/10.1080/87559129.2021.1901292

. Witten, S., Böhm, H., Aulrich, K. (2019). Effect of variety and environment on the contents of crude nutrients and amino acids in organically produced cereal and legume grains. Organic Agriculture, 10(2), 199–219. https://doi.org/10.1007/s13165-019-00261-7

. Yiğit, A., Bielska, P., Cais-Sokolińska, D., Samur, G. (2023). Whey proteins as a functional food: Health effects, functional properties, and applications in food. Journal of the American Nutrition Association, 42(8), 758–768. https://doi.org/10.1080/27697061.2023.2169208

. Martínez, J. M., Delso, C., Álvarez, I., Raso, J. (2020). Pulsed electric field‐assisted extraction of valuable compounds from microorganisms. Comprehensive Reviews in Food Science and Food Safety, 19(2), 530–552. https://doi.org/10.1111/1541-4337.12512

. Aziznia, S., Askari, G., Emamdjomeh, Z., Salami, M. (2023). Effect of ultrasonic assisted grafting on the structural and functional properties of mung bean protein isolate conjugated with maltodextrin through maillard reaction. International Journal of Biological Macromolecules, 254, 127616. https://doi.org/10.1016/j.ijbiomac.2023.127616

. Garrido-Galand, S., Asensio-Grau, A., Calvo-Lerma, J., Heredia, A., Andrés, A. (2021). The potential of fermentation on nutritional and technological improvement of cereal and legume flours: A review. Food Research International, 145, 110398. https://doi.org/10.1016/j.foodres.2021.110398

. Tas, A. A., Shah, A. U. (2021). The replacement of cereals by legumes in extruded snack foods: Science, technology and challenges. Trends in Food Science & Technology, 116, 701–711. https://doi.org/10.1016/j.tifs.2021.08.016

. Licandro, H., Ho, P. H., Nguyen, T. K. C., Petchkongkaew, A., Van Nguyen, H., Chu-Ky, S., Nguyen, T. V. A., Lorn, D., Waché, Y. (2019). How fermentation by lactic acid bacteria can address safety issues in legumes food products? Food Control, 110, 106957. https://doi.org/10.1016/j.foodcont.2019.106957

. Pathiraje, D., Carlin, J., Der, T., Wanasundara, J. P. D., Shand, P. J. (2023). Generating Multi-Functional pulse ingredients for Processed meat Products—Scientific Evaluation of Infrared-Treated Lentils. Foods, 12(8), 1722. https://doi.org/10.3390/foods12081722

. Ruiz-Zambrano, N. L., Pérez-Carrillo, E., Serna-Saldívar, S. O., Tejada-Ortigoza, V. (2023). Effect of thermal, nonthermal, and combined treatments on functional and nutritional properties of chickpeas. Critical Reviews in Food Science and Nutrition, 64(31), 11356–11374. https://doi.org/10.1080/10408398.2023.2237577

. Joshi-Saha, A., Sethy, S. K., Misra, G., Dixit, G. P., Srivastava, A. K., Sarker, A. (2022). Biofortified legumes: Present scenario, possibilities and challenges. Field Crops Research, 279, 108467. https://doi.org/10.1016/j.fcr.2022.108467

. De Oliveira Schmidt, H., De Oliveira, V. R. (2023). Overview of the Incorporation of Legumes into New Food Options: An Approach on Versatility, Nutritional, Technological, and Sensory Quality. Foods, 12(13), 2586. https://doi.org/10.3390/foods12132586

. Chatur, P., Johnson, S., Coorey, R., Bhattarai, R. R., Bennett, S. J. (2022). The effect of high pressure processing on textural, bioactive and digestibility properties of cooked kimberley large Kabuli chickpeas. Frontiers in Nutrition, 9. https://doi.org/10.3389/fnut.2022.847877

. Perera, D., Devkota, L., Garnier, G., Panozzo, J., Dhital, S. (2023). Hard-to-cook phenomenon in common legumes: Chemistry, mechanisms and utilisation. Food Chemistry, 415, 135743. https://doi.org/10.1016/j.foodchem.2023.135743

. Wang, Y., Wang, Y., Li, K., Bai, Y., Li, B., Xu, W. (2020). Effect of high intensity ultrasound on physicochemical, interfacial and gel properties of chickpea protein isolate. LWT, 129, 109563. https://doi.org/10.1016/j.lwt.2020.109563

. Mozafarpour, R., Koocheki, A., Nicolai, T. (2022). Modification of grass pea protein isolate (Lathyrus sativus L.) using high intensity ultrasound treatment: Structure and functional properties. Food Research International, 158, 111520. https://doi.org/10.1016/j.foodres.2022.111520

. Teixeira, R. F., Filho, C. A. B., De Oliveira, D., Zielinski, A. A. F. (2023). Prospects on emerging eco-friendly and innovative technologies to add value to dry bean proteins. Critical Reviews in Food Science and Nutrition, 64(28), 10256–10280. https://doi.org/10.1080/10408398.2023.2222179

. Saffarionpour, S. (2023). Off-Flavors in pulses and grain Legumes and Processing Approaches for Controlling Flavor-Plant Protein interaction: Application Prospects in Plant-Based Alternative Foods. Food and Bioprocess Technology, 17(5), 1141–1182. https://doi.org/10.1007/s11947-023-03148-4

. Senanayake, D., Torley, P. J., Chandrapala, J., Terefe, N. S. (2023). Microbial fermentation for improving the sensory, nutritional and functional attributes of legumes. Fermentation, 9(7), 635. https://doi.org/10.3390/fermentation9070635

. Ohanenye, I. C., Ekezie, F.-G. C., Sarteshnizi, R. A., Boachie, R. T., Emenike, C. U., Sun, X., Nwachukwu, I. D., Udenigwe, C. C. (2022). Legume seed protein digestibility as influenced by traditional and emerging physical processing technologies. Foods, 11(15), 2299. https://doi.org/10.3390/foods11152299

. Fernando, S. (2021). Pulse protein ingredient modification. Journal of the Science of Food and Agriculture, 102(3), 892–897. https://doi.org/10.1002/jsfa.11548

. Tidåker, P., Potter, H. K., Carlsson, G., Röös, E. (2021). Towards sustainable consumption of legumes: How origin, processing and transport affect the environmental impact of pulses. Sustainable Production and Consumption, 27, 496–508. https://doi.org/10.1016/j.spc.2021.01.017

. Wei, Y., Ning, D., Sun, L., Gu, Y., Zhuang, Y., Ding, Y., Fan, X. (2025). Breaking barriers: Elevating legume protein functionality in food products through non-thermal technologies. Food Chemistry X, 25, 102169. https://doi.org/10.1016/j.fochx.2025.102169

. Affrifah, N. S., Uebersax, M. A., Amin, S. (2023). Nutritional significance, value‐added applications, and consumer perceptions of food legumes: A review. Legume Science, 5(4). https://doi.org/10.1002/leg3.192

. Bautista-Expósito, S., Vandenberg, A., Peñas, E., Frias, J., Martínez-Villaluenga, C. (2021). Lentil and fava bean with contrasting germination kinetics: a focus on digestion of proteins and bioactivity of resistant peptides. Frontiers in Plant Science, 12. https://doi.org/10.3389/fpls.2021.754287

. Oh, S.-M., Song, S.-B., Lee, J.-S., Oh, Y.-G., Choi, Y.-C., Lee, J.-H., Kwak, J. (2022). Effect of Microwave Treatment on Adzuki Beans (Vigna angularis L.) under Dry State—Analyzing Microstructure, Water Absorption, and Antioxidant Properties. Foods, 11(11), 1653. https://doi.org/10.3390/foods11111653

. Lai, X.-J., Chen, J.-Q., Nie, J., Guo, P.-F., Manzoor, M. F., Huang, Y.-Y., Li, J., Lin, S.-Y., Zeng, X.-A., Wang, R. (2024). Enhancement of extraction efficiency and functional properties of chickpea protein isolate using pulsed electric field combined with ultrasound treatment. Ultrasonics Sonochemistry, 111, 107089. https://doi.org/10.1016/j.ultsonch.2024.107089

. Saran, V., Pavithra, R., Koli, V., Dattatrya, P. A., Nikashini, T., Ashika, R., Gowda, N. A. N., Sunil, C. K. (2024). Ultrasound modification of techno-functional, structural, and physico-chemical properties of legume proteins: A Review. Food Bioscience, 60, 104456. https://doi.org/10.1016/j.fbio.2024.104456

. Bandyopadhyay, M., Guha, S., Naldrett, M. J., Alvarez, S., Majumder, K. (2021). Evaluating the effect of high‐pressure processing in contrast to boiling on the antioxidant activity from alcalase hydrolysate of Great Northern Beans (Phaseolus vulgaris). Journal of Food Biochemistry, 45(12). https://doi.org/10.1111/jfbc.14004

. Sridhar, K., Bouhallab, S., Croguennec, T., Renard, D., Lechevalier, V. (2022). Application of high-pressure and ultrasound technologies for legume proteins as wall material in microencapsulation: New insights and advances. Trends in Food Science & Technology, 127, 49–62. https://doi.org/10.1016/j.tifs.2022.07.006

. Lin, T., Fernández-Fraguas, C. (2020). Effect of thermal and high-pressure processing on the thermo-rheological and functional properties of common bean (Phaseolus vulgaris L.) flours. LWT, 127, 109325. https://doi.org/10.1016/j.lwt.2020.109325

. Bhargava, N., Mor, R. S., Kumar, K., Sharanagat, V. S. (2020). Advances in application of ultrasound in food processing: A review. Ultrasonics Sonochemistry, 70, 105293. https://doi.org/10.1016/j.ultsonch.2020.105293

. Badjona, A., Bradshaw, R., Millman, C., Howarth, M., Dubey, B. (2024). Structural, thermal, and physicochemical properties of ultrasound-assisted extraction of faba bean protein isolate (FPI). Journal of Food Engineering, 377, 112082. https://doi.org/10.1016/j.jfoodeng.2024.112082

. Kang, S., Zhang, J., Guo, X., Lei, Y., Yang, M. (2022). Effects of ultrasonic treatment on the structure, functional properties of chickpea protein isolate and its digestibility in vitro. Foods, 11 (6), 880. https://doi.org/10.3390/foods11060880

. Das, D., Panesar, P. S., Saini, C. S. (2023). Ultrasonic extraction of soy protein isolate: Characterization and comparison with microwave and enzymatic extraction methods. Journal of Food Science, 88(7), 2758–2779. https://doi.org/10.1111/1750-3841.16654

. Locatelli, M., Coïsson, J. D., Travaglia, F., Cereti, E., Garino, C., D’Andrea, M., Martelli, A., Arlorio, M. (2011). Chemotype and genotype chemometrical evaluation applied to authentication and traceability of “Tonda Gentile Trilobata” hazelnuts from Piedmont (Italy). Food Chemistry, 129(4), 1865–1873. https://doi.org/10.1016/j.foodchem.2011.05.134

. Siddiq, M., Uebersax, M. A. (2021). Dry Beans and Pulses, Wiley. https://doi.org/10.1002/9781119776802

. Ashraf, J., Liu, L., Awais, M., Xiao, T., Wang, L., Zhou, X., Tong, L.-T., Zhou, S. (2020). Effect of thermosonication pre-treatment on mung bean (Vigna radiata) and white kidney bean (Phaseolus vulgaris) proteins: Enzymatic hydrolysis, cholesterol lowering activity and structural characterization. Ultrasonics Sonochemistry, 66, 105121. https://doi.org/10.1016/j.ultsonch.2020.105121

. Yeasmin, F., Prasad, P., Sahu, J. K. (2024). Effect of ultrasound on physicochemical, functional and antioxidant properties of red kidney bean (Phaseolus vulgaris L.) proteins extract. Food Bioscience, 57, 103599. https://doi.org/10.1016/j.fbio.2024.103599

. Bender, D., Yamsaengsung, R., Waziiroh, E., Schoenlechner, R., Jaeger, H. (2024). Effect of ultrasound‐assisted soaking on the hydration kinetics and physicochemical properties of chickpeas. International Journal of Food Science & Technology, 59 (4), 2221–2235. https://doi.org/10.1111/ijfs.16916

. Lukacs, M., Somogyi, T., Mukite, B. M., Vitális, F., Kovacs, Z., Rédey, Á., Stefaniga, T., Zsom, T., Kiskó, G., Zsom-Muha, V. (2025). Investigation of the Ultrasonic Treatment-Assisted soaking process of different red kidney beans and compositional analysis of the soaking water by NIR spectroscopy. Sensors, 25(2), 313. https://doi.org/10.3390/s25020313

. Loushigam, G., Shanmugam, A. (2023). Modifications to functional and biological properties of proteins of cowpea pulse crop by ultrasound-assisted extraction. Ultrasonics Sonochemistry, 97, 106448. https://doi.org/10.1016/j.ultsonch.2023.106448

. Aghababaei, F., McClements, D. J., Hadidi, M. (2024). Ultrasound processing for enhanced digestibility of plant proteins. Food Hydrocolloids, 155, 110188. https://doi.org/10.1016/j.foodhyd.2024.110188

. John, R., Bartwal, A., Jeyaseelan, C., Sharma, P., Ananthan, R., Singh, A. K., Singh, M., Gayacharan, N., Rana, J. C., Bhardwaj, R. (2023). Rice bean-adzuki bean multitrait near infrared reflectance spectroscopy prediction model: a rapid mining tool for trait-specific germplasm. Frontiers in Nutrition, 10. https://doi.org/10.3389/fnut.2023.1224955

. Lao, Y., Ye, Q., Wang, Y., Selomulya, C. (2024). Modulating digestibility and mitigating beany flavor of pea protein. Food Reviews International, 40(9), 3129–3158. https://doi.org/10.1080/87559129.2024.2346329

. Najib, T., Heydari, M. M., Meda, V. (2022). Combination of germination and innovative microwave-assisted infrared drying of lentils: effect of physicochemical properties of different varieties on water uptake, germination, and drying kinetics. Applied Food Research, 2(1), 100040. https://doi.org/10.1016/j.afres.2021.100040

. Pasqualone, A., Costantini, M., Coldea, T. E., Summo, C. (2020). Use of legumes in extrusion cooking: a review. Foods, 9(7), 958. https://doi.org/10.3390/foods9070958

. Rico, D., Cano, A. B., Martín-Diana, A. B. (2021). Pulse-Cereal blend extrusion for improving the antioxidant properties of a Gluten-Free flour. Molecules, 26(18), 5578. https://doi.org/10.3390/molecules26185578

. Zang, Y., Wang, S., Gao, Y., Sun, C., Zhao, Y., Cao, Y., Lu, W., Zhang, Y., Fang, Y. (2024). High moisture extrusion of pulse proteins: texture, structure, and in vitro digestion characteristics of extrudates. Food Hydrocolloids, 110676. https://doi.org/10.1016/j.foodhyd.2024.110676

. Ciudad-Mulero, M., Vega, E. N., García-Herrera, P., Pedrosa, M. M., Arribas, C., De J Berrios, J., Cámara, M., Fernández-Ruiz, V., Morales, P. (2022). Extrusion cooking effect on carbohydrate fraction in novel Gluten-Free flours based on chickpea and rice. Molecules, 27 (3), 1143. https://doi.org/10.3390/molecules27031143

. Ek, P., Baner, J. M., Ganjyal, G. M. (2020). Extrusion processing of cereal grains, tubers, and seeds. In Elsevier eBooks. https://doi.org/10.1016/b978-0-12-815360-4.00008-0

. Pedrosa, M. M., Guillamón, E., Arribas, C. (2021). Autoclaved and extruded legumes as a source of bioactive phytochemicals: a review. Foods, 10(2), 379. https://doi.org/10.3390/foods10020379

. Cotacallapa-Sucapuca, M., Vega, E. N., Maieves, H. A., De J Berrios, J., Morales, P., Fernández-Ruiz, V., Cámara, M. (2021). Extrusion process as an alternative to improve pulses products consumption. a review. Foods, 10(5), 1096. https://doi.org/10.3390/foods10051096

. Kristiawan, M., Della Valle, G., Berzin, F. (2022). Extrusion simulation for the design of cereal and legume foods. Foods, 11(12), 1780. https://doi.org/10.3390/foods11121780

. Andersone-Trezina, E., Kince, T. (2022). Use of peas (Pisum Sativum L.) and beans (Phaseolus Vulgaris L.) In high-moisture food extrusion: a review. Research for Rural Development/Research for Rural Development (Online), 37, 93–99. https://doi.org/10.22616/rrd.28.2022.014

. Jain, R., Goomer, S. (2023). Understanding extrusion technology for cereal–pulse blends: A review. Cogent Food & Agriculture, 9(1). https://doi.org/10.1080/23311932.2023.2253714

. Cargo-Froom, C. L., Newkirk, R. W., Marinangeli, C. P. F., Shoveller, A. K., Ai, Y., Columbus, D. A. (2022). The effects of extrusion on nutrient content of Canadian pulses with a focus on protein and amino acids. Canadian Journal of Animal Science, 103(1), 44–58. https://doi.org/10.1139/cjas-2022-0088

. Duque-Estrada, P., Hardiman, K., Dam, A. B., Dodge, N., Aaslyng, M. D., Petersen, I. L. (2023). Protein blends and extrusion processing to improve the nutritional quality of plant proteins. Food & Function, 14(16), 7361–7374. https://doi.org/10.1039/d2fo03912e

. Faliarizao, N., De J Berrios, J., Dolan, K. D. (2024). Value‐Added processing of food legumes using extrusion Technology: A review. Legume Science, 6(2). https://doi.org/10.1002/leg3.231

. Siitonen, A., Nieminen, F., Kallio, V., Tuccillo, F., Kantanen, K., Ramos-Diaz, J. M., Jouppila, K., Piironen, V., Kariluoto, S., Edelmann, M. (2024). B vitamins in legume ingredients and their retention in high moisture extrusion. Foods, 13(5), 637. https://doi.org/10.3390/foods13050637

. Bakhsh, A., Son, Y., Kim, B., Chin, J., Park, S. (2023). Optimizing extrusion processes: Development of extrudates utilizing ISP and wheat gluten, incorporating diverse concentrations of rice or legume varieties. Journal of Agriculture and Food Research, 15, 100915. https://doi.org/10.1016/j.jafr.2023.100915

. Gu, J., Bk, A., Wu, H., Lu, P., Nawaz, M. A., Barrow, C. J., Dunshea, F. R., Suleria, H. A. R. (2022). Impact of processing and storage on protein digestibility and bioavailability of legumes. Food Reviews International, 39(7), 4697–4724. https://doi.org/10.1080/87559129.2022.2039690

. Altan, A., Yağci, S. (2023). Physicochemical characteristics and structural changes of fermented faba bean extrudates prepared by twin-screw extrusion. Food Chemistry, 411, 135502. https://doi.org/10.1016/j.foodchem.2023.135502

. Guo, L., Wang, X., Ren, Y., Zhang, X., Li, Q., Zhang, C., Qian, J.-Y. (2023). Outcomes of structure, function and flavor of pea protein isolate treated by AC, DC and pulsed electric fields. Food Research International, 176, 113817. https://doi.org/10.1016/j.foodres.2023.113817

. Mulla, M. Z., Subramanian, P., Dar, B. N. (2022). Functionalization of legume proteins using high pressure processing: Effect on technofunctional properties and digestibility of legume proteins. LWT, 158, 113106. https://doi.org/10.1016/j.lwt.2022.113106

. Peyrano, F., De Lamballerie, M., Avanza, M. V., Speroni, F. (2020). Gelation of cowpea proteins induced by high hydrostatic pressure. Food Hydrocolloids, 111, 106191. https://doi.org/10.1016/j.foodhyd.2020.106191

. Yanni, A. E., Iakovidi, S., Vasilikopoulou, E., Karathanos, V. T. (2023). Legumes: a vehicle for Transition to Sustainability. Nutrients, 16(1), 98. https://doi.org/10.3390/nu16010098

. Sá, A. G. A., Da Silva, D. C., Pacheco, M. T. B., Moreno, Y. M. F., Carciofi, B. A. M. (2021). Oilseed by-products as plant-based protein sources: Amino acid profile and digestibility. Future Foods, 3, 100023. https://doi.org/10.1016/j.fufo.2021.100023

. Kamani, M. H., Neji, C., Fitzsimons, S. M., Fenelon, M. A., Murphy, E. G. (2023). Unlocking the nutritional and functional potential of legume waste to produce protein ingredients. Critical Reviews in Food Science and Nutrition, 64(21), 7311–7329. https://doi.org/10.1080/10408398.2023.2184322

. Hall, A. E., Moraru, C. I. (2021). Structure and function of pea, lentil and faba bean proteins treated by high pressure processing and heat treatment. LWT, 152, 112349. https://doi.org/10.1016/j.lwt.2021.112349

. Wiesinger, J. A., Marsolais, F., Glahn, R. P. (2021). Health Implications and Nutrient Bioavailability of Bioactive Compounds in Dry Beans and Other Pulses. In Dry Beans and Pulses. https://doi.org/10.1002/9781119776802.ch20

. Gharibzahedi, S. M. T., Smith, B. (2020). Effects of high hydrostatic pressure on the quality and functionality of protein isolates, concentrates, and hydrolysates derived from pulse legumes: A review. Trends in Food Science & Technology, 107, 466–479. https://doi.org/10.1016/j.tifs.2020.11.016

. Sosa, E. F., Thompson, C., Chaves, M. G., Acevedo, B. A., Avanza, M. V. (2019). Legume seeds treated by high hydrostatic pressure: Effect on functional properties of flours. Food and Bioprocess Technology, 13(2), 323–340. https://doi.org/10.1007/s11947-019-02386-9

. Kamboj, S., Gupta, N., Bandral, J. D., Gandotra, G., Anjum, N. (2020). Food safety and hygiene: A review. International Journal of Chemical Studies, 8(2), 358–368. https://doi.org/10.22271/chemi.2020.v8.i2f.8794

. Erem, E., Icyer, N. C., Tatlisu, N. B., Kilicli, M., Kaderoglu, G. H., Toker, Ö. S. (2021). A new trend among plant-based food ingredients in food processing technology: Aquafaba. Critical Reviews in Food Science and Nutrition, 63(20), 4467–4484. https://doi.org/10.1080/10408398.2021.2002259

. Nguyen, T. T. B., Li, D. (2021). A systematic literature review of food safety management system implementation in global supply chains. British Food Journal, 124(10), 3014–3031. https://doi.org/10.1108/bfj-05-2021-0476

. Hasani, M., Camacho-Martinez, S. V., Warriner, K. (2024). Food safety management systems. In Elsevier eBooks: pp 241–254. https://doi.org/10.1016/b978-0-443-15690-8.00021-7

. Carlini, B., Lucini, C., Velázquez, J. (2024). The Role of Legumes in the Sustainable Mediterranean Diet: Analysis of the Consumption of Legumes in the Mediterranean Population over the Last Ten Years a PRISMA Statement Methodology. Sustainability, 16(7), 3081. https://doi.org/10.3390/su16073081

. Sharma, A. (2020). A review on traditional technology and safety challenges with regard to antinutrients in legume foods. Journal of Food Science and Technology, 58(8), 2863–2883. https://doi.org/10.1007/s13197-020-04883-8

. Knorr, D. (2023). Food processing: Legacy, significance and challenges. Trends in Food Science & Technology, 143, 104270. https://doi.org/10.1016/j.tifs.2023.104270

. Lee, J. C., Neonaki, M., Alexopoulos, A., Varzakas, T. (2023). Case Studies of Small-Medium Food Enterprises around the World: Major Constraints and Benefits from the Implementation of Food Safety Management Systems. Foods, 12 (17), 3218. https://doi.org/10.3390/foods12173218

. Ding, Y., Ban, Q., Wu, Y., Sun, Y., Zhou, Z., Wang, Q., Cheng, J., Xiao, H. (2021). Effect of high hydrostatic pressure on the edible quality, health and safety attributes of plant-based foods represented by cereals and legumes: a review. Critical Reviews in Food Science and Nutrition, 63 (20), 4636–4654. https://doi.org/10.1080/10408398.2021.2005531

. Sun, X., Ohanenye, I. C., Ahmed, T., Udenigwe, C. C. (2020). Microwave treatment increased protein digestibility of pigeon pea (Cajanus cajan) flour: Elucidation of underlying mechanisms. Food Chemistry, 329, 127196. https://doi.org/10.1016/j.foodchem.2020.127196

. Nardi, V. A. M., Auler, D. P., Teixeira, R. (2020). Food safety in global supply chains: A literature review. Journal of Food Science, 85 (4), 883–891. https://doi.org/10.1111/1750-3841.14999

. Mishra, S., Singh, R., Upadhyay, A., Mishra, S., Shukla, S. (2023). Emerging trends in processing for cereal and legume-based beverages: A review. Future Foods, 8, 100257. https://doi.org/10.1016/j.fufo.2023.100257

. Shah, H., Ahmed, L., Barry-Ryan, C. (2024). Ensuring compliance: A review of EU regulations and standards for incorporating legume and legume by-product proteins in food formulations. Heliyon, 10(21), e39821. https://doi.org/10.1016/j.heliyon.2024.e39821

. Bessada, S. M. F., Barreira, J. C. M., Oliveira, M. B. P. P. (2019). Pulses and food security: Dietary protein, digestibility, bioactive and functional properties. Trends in Food Science & Technology, 93, 53–68. https://doi.org/10.1016/j.tifs.2019.08.022

. Semwal, J., Meera. (2020). Infrared radiation: Impact on physicochemical and functional characteristics of grain starch. Starch - Stärke, 73(3–4). https://doi.org/10.1002/star.202000112

. Rana, R. L., Tricase, C., De Cesare, L. (2021). Blockchain technology for a sustainable agri-food supply chain. British Food Journal, 123 (11), 3471–3485. https://doi.org/10.1108/bfj-09-2020-0832

. Malik, S., Krishnaswamy, K., Mustapha, A. (2021). Hazard Analysis and Risk-Based Preventive Controls (HARPC): Current food safety and quality standards for complementary foods. Foods, 10(9), 2199. https://doi.org/10.3390/foods10092199

. Radoiu, M., Calvo-Carrascal, M. A., Dodds, C., Binner, E.R. (2021). Flash microwave denaturation of POD and LOX enzymes in whole yellow peas. Chemical Engineering and Processing - Process Intensification, 169, 108601. https://doi.org/10.1016/j.cep.2021.108601

. Alandia, G., Pulvento, C., Sellami, M. H., Hoidal, N., Anemone, T., Nigussie, E., Agüero, J. J., Lavini, A., Jacobsen, S. -e. (2020). Grain legumes may enhance High-Quality food production in Europe. In Environment & policy. https://doi.org/10.1007/978-3-319-90472-6_2

. Mahalaxmi, S., Himashree, P., Malini, B., Sunil, C. K. (2022). Effect of microwave treatment on the structural and functional properties of proteins in lentil flour. Food Chemistry Advances, 1, 100147. https://doi.org/10.1016/j.focha.2022.100147

. Duan, H.-X., Luo, C.-L., Wang, X., Cheng, Y.-S., Abrar, M., Batool, A. (2024). Responses of legumes to rhizobia and arbuscular mycorrhizal fungi under abiotic stresses: A Global Meta-Analysis. Agronomy, 14 (11), 2597. https://doi.org/10.3390/agronomy14112597

. Abass, N. T., Eruaga, N. M. A., Itua, N. E. O., Bature, N. J. T. (2024). ADVANCING FOOD SAFETY THROUGH IOT: REAL-TIME MONITORING AND CONTROL SYSTEMS. International Medical Science Research Journal, 4 (3), 276–283. https://doi.org/10.51594/imsrj.v4i3.919

. Bosona, T., Gebresenbet, G. (2023). The role of blockchain technology in promoting traceability systems in Agri-Food production and supply chains. Sensors, 23 (11), 5342. https://doi.org/10.3390/s23115342

. Li, M., Wang, B., Lv, W., Zhao, D. (2022). Effect of ultrasound pretreatment on the drying kinetics and characteristics of pregelatinized kidney beans based on microwave-assisted drying. Food Chemistry, 397, 133806. https://doi.org/10.1016/j.foodchem.2022.133806

. Antonenko, А., Tolok, G., Brovenko, T., Biriukova, O., Ratushenko, A., Gorkun, A. (2024). AUDIT AND QUALITY CONTROL OF FOOD PRODUCTS IN EU COUNTRIES AND THE WORLD. Measuring and Computing Devices in Technological Processes, No. 4, 18–22. https://doi.org/10.31891/2219-9365-2024-80-2

. Xu, Y., Li, X., Zeng, X., Cao, J., Jiang, W. (2020). Application of blockchain technology in food safety control:current trends and future prospects. Critical Reviews in Food Science and Nutrition, 62(10), 2800–2819. https://doi.org/10.1080/10408398.2020.1858752

. Segura, M., Maroto, C., Segura, B., Casas-Rosal, J. C. (2020). Improving food supply chain management by a sustainable approach to supplier evaluation. Mathematics, 8(11), 1952. https://doi.org/10.3390/math8111952

. Heydari, M. M., Kauldhar, B. S., Meda, V. (2020). Kinetics of a thin‐layer microwave‐assisted infrared drying of lentil seeds. Legume Science, 2(2). https://doi.org/10.1002/leg3.31

. Badjona, A., Bradshaw, R., Millman, C., Howarth, M., Dubey, B. (2023). FABA Bean Processing: Thermal and Non-Thermal Processing on chemical, antinutritional factors, and pharmacological properties. Molecules, 28 (14), 5431. https://doi.org/10.3390/molecules28145431

. Zuluaga, A. M., Mena-García, A., Monzón, A. C. S., Rada-Mendoza, M., Chito, D. M., Ruiz-Matute, A. I., Sanz, M. L. (2020). Microwave assisted extraction of inositols for the valorization of legume by-products. LWT, 133, 109971. https://doi.org/10.1016/j.lwt.2020.109971

. Safitri, R. A., Van Asselt, E. D., Müller-Maatsch, J., Vogelgsang, S., Dapcevic-Hadnadev, T., De Nijs, M. (2024). Generic food safety assessment: A framework to evaluate food safety hazards emerging from change(s) in the primary production system – A case study involving intercropping. Journal of Food Protection, 100371. https://doi.org/10.1016/j.jfp.2024.100371

. Bomba, M. Ya., Susol, N. Ya. (2020). Main requirements for food safety management systems under international standards: BRС, IFS, FSSC 22000, ISO 22000, Global GAP, SQF. Scientific Messenger of LNU of Veterinary Medicine and Biotechnologies, 22(93), 18–25. https://doi.org/10.32718/nvlvet-f9304

. Pierre, J. F. (2024). Legumes: cornerstones of global food security and sustainable agriculture. In IntechOpen eBooks. https://doi.org/10.5772/intechopen.1006180

. Amoah, I., Ascione, A., Muthanna, F., Feraco, A., Camajani, E., Gorini, S., Armani, A., Caprio, M., Lombardo, M. (2023). Sustainable Strategies for Increasing legume Consumption: Culinary and educational approaches. Foods, 12(11), 2265. https://doi.org/10.3390/foods12112265

. Lau, H., Nakandala, D., Shum, P. K. A (2018). business process decision model for fresh-food supplier evaluation. Business Process Management Journal, 24(3), 716–744. https://doi.org/10.1108/bpmj-01-2016-0015

. Wu, X.-F., Zhang, M., Bhandari, B. (2019). A novel infrared freeze drying (IRFD) technology to lower the energy consumption and keep the quality of Cordyceps militaris. Innovative Food Science & Emerging Technologies, 54, 34–42. https://doi.org/10.1016/j.ifset.2019.03.003

. Heydari, M. M., Najib, T., Meda, V. (2022). Investigating starch and protein structure alterations of the processed lentil by microwave-assisted infrared thermal treatment and their correlation with the modified properties. Food Chemistry Advances, 1, 100091. https://doi.org/10.1016/j.focha.2022.100091

. Guldiken, B., Konieczny, D., Franczyk, A., Satiro, V., Pickard, M., Wang, N., House, J., Nickerson, M. T. (2022). Impacts of infrared heating and tempering on the chemical composition, morphological, functional properties of navy bean and chickpea flours. European Food Research and Technology, 248(3), 767–781. https://doi.org/10.1007/s00217-021-03918-4

. Rahman, M. M., Refat, B., Zhang, H., Zhang, W., Yu, P. (2018). Detect molecular spectral features of newly developed Vicia faba varieties and protein metabolic characteristics in ruminant system using advanced synchrotron radiation based infrared microspectroscopy: A preliminary study. Spectrochimica Acta Part a Molecular and Biomolecular Spectroscopy, 206, 413–420. https://doi.org/10.1016/j.saa.2018.08.022

. Iqbal, A., Hosseini, A. F., Rizvi, S. S. H. (2025). Supercritical fluid extrusion of pea flour and pea protein concentrate: Effects on off‐flavor removal and sensory improvement. Journal of Food Science, 90(1). https://doi.org/10.1111/1750-3841.70004

. Acquah, C., Ohemeng-Boahen, G., Power, K. A., Tosh, S. M. (2021). The effect of processing on bioactive compounds and nutritional qualities of pulses in meeting the Sustainable Development Goal 2. Frontiers in Sustainable Food Systems, 5. https://doi.org/10.3389/fsufs.2021.681662

. López-Calabozo, R., Liberal, Â., Fernandes, Â., Revilla, I., Ferreira, I. C. F. R., Barros, L., Vivar-Quintana, A. M. (2024). Determination of carbohydrate composition in lentils using Near-Infrared Spectroscopy. Sensors, 24(13), 4232. https://doi.org/10.3390/s24134232

. Manyatsi, T. S., Al-Hilphy, A. R., Majzoobi, M., Farahnaky, A., Gavahian, M. (2022). Effects of infrared heating as an emerging thermal technology on physicochemical properties of foods. Critical Reviews in Food Science and Nutrition, 63(24), 6840–6859. https://doi.org/10.1080/10408398.2022.2043822

. Deepika, S., Sutar, P. P. (2023). Spectral selective infrared heating of food components based on optical characteristics and penetration depth: a critical review. Critical Reviews in Food Science and Nutrition, 1–23. https://doi.org/10.1080/10408398.2023.2227899

. Liu, S., Ren, Y., Yin, H., Nickerson, M., Pickard, M., Ai, Y. (2022). Improvement of the nutritional quality of lentil flours by infrared heating of seeds varying in size. Food Chemistry, 396, 133649. https://doi.org/10.1016/j.foodchem.2022.133649

. Sakare, P., Prasad, N., Thombare, N., Singh, R., Sharma, S. C. (2020). Infrared drying of food materials: recent advances. Food Engineering Reviews, 12(3), 381–398. https://doi.org/10.1007/s12393-020-09237-w

. Mizutani, Y., Shibata, M., Yamada, S., Nambu, Y., Hirotsuka, M., Matsumura, Y. (2018). Effects of heat treatment under low moisture conditions on the protein and oil in soybean seeds. Food Chemistry, 275, 577–584. https://doi.org/10.1016/j.foodchem.2018.09.139

. Rivera, J., Siliveru, K., Li, Y. (2022). A comprehensive review on pulse protein fractionation and extraction: processes, functionality, and food applications. Critical Reviews in Food Science and Nutrition, 64(13), 4179–4201. https://doi.org/10.1080/10408398.2022.2139223

. Galvão, A. M. M. T., Rasera, M. L., De Figueiredo Furtado, G., Karatay, G. G. B., Tavares, G. M., Hubinger, M. D. (2024). Lentil protein isolate (Lens culinaris) subjected to ultrasound treatment combined or not with heat-treatment: structural characterization and ability to stabilize high internal phase emulsions. Food Research International, 183, 114212. https://doi.org/10.1016/j.foodres.2024.114212

. Daba, S. D., Honigs, D., McGee, R. J., Kiszonas, A. M. (2022). Prediction of Protein Concentration in Pea (Pisum sativum L.) Using Near-Infrared Spectroscopy (NIRS) Systems. Foods, 11(22), 3701. https://doi.org/10.3390/foods11223701

. Ferreira, H., Pinto, E., Vasconcelos, M. W. (2021). Legumes as a cornerstone of the transition toward more sustainable Agri-Food systems and diets in Europe. Frontiers in Sustainable Food Systems, 5. https://doi.org/10.3389/fsufs.2021.694121

. Ahmed, J. (2021). Emerging technologies for pulse processing. In Elsevier eBooks. https://doi.org/10.1016/b978-0-12-818184-3.00011-8

. Das, P. C., Baik, O., Tabil, L. G., Rajagopalan, N. (2025). Impact of radiofrequency and microwave heating on the nutritional and antinutritional properties of pulses: a review. Legume Science, 7(1). https://doi.org/10.1002/leg3.70025

. Johnston, C., Leong, S. Y., Teape, C., Liesaputra, V., Oey, I. (2024). Low-intensity pulsed electric field processing prior to germination improves in vitro digestibility of faba bean (Vicia faba L.) flour and its derived products: A case study on legume-enriched wheat bread. Food Chemistry, 449, 139321. https://doi.org/10.1016/j.foodchem.2024.139321

. Cao, H., Wang, X., Liu, J., Sun, Z., Yu, Z., Battino, M., El‐Seedi, H., Guan, X. (2023). Mechanistic insights into the changes of enzyme activity in food processing under microwave irradiation. Comprehensive Reviews in Food Science and Food Safety, 22(3), 2465–2487. https://doi.org/10.1111/1541-4337.13154

. Gharibzahedi, S. M. T., Smith, B., Altintas, Z. (2022). Bioactive and health-promoting properties of enzymatic hydrolysates of legume proteins: a review. Critical Reviews in Food Science and Nutrition, 64(9), 2548–2578. https://doi.org/10.1080/10408398.2022.2124399

. Najib, T., Heydari, M. M., Tu, K., Meda, V. (2023). Modification in starch structure of soaked and germinated lentil seeds under various thermal processing methods, including conventional, microwave, and microwave-assisted techniques. Food Chemistry Advances, 2, 100267. https://doi.org/10.1016/j.focha.2023.100267

. Zhou, J., Li, M., Bai, Q., De Souza, T. S. P., Barrow, C., Dunshea, F., Suleria, H. a. R. (2023). Effects of different processing methods on pulses Phytochemicals: An Overview. Food Reviews International, 40(4), 1138–1195. https://doi.org/10.1080/87559129.2023.2212041

. İşçimen, E. M., Hayta, M. (2021). Microwave-assisted aqueous two-phase system based extraction of phenolics from pulses: Antioxidant properties, characterization and encapsulation. Industrial Crops and Products, 173, 114144. https://doi.org/10.1016/j.indcrop.2021.114144

. Bou, R., Navarro‐Vozmediano, P., Domínguez, R., López‐Gómez, M., Pinent, M., Ribas‐Agustí, A., Benedito, J. J., Lorenzo, J. M., Terra, X., García‐Pérez, J. V., Pateiro, M., Herrera‐Cervera, J. A., Jorba‐Martín, R. (2022). Application of emerging technologies to obtain legume protein isolates with improved techno‐functional properties and health effects. Comprehensive Reviews in Food Science and Food Safety, 21(3), 2200–2232. https://doi.org/10.1111/1541-4337.12936

. Laing, E., Stone, A. K., Shi, D., Pickard, M., House, J. D., Wang, N., Nickerson, M. T. (2023). Effect of infrared heating on the nutritional properties of yellow pea and green lentil flours. Cereal Chemistry, 100(3), 614–627. https://doi.org/10.1002/cche.10653

. Sá, A. G. A., Laurindo, J. B., Moreno, Y. M. F., Carciofi, B. A. M. (2022). Influence of emerging technologies on the utilization of plant proteins. Frontiers in Nutrition, 9. https://doi.org/10.3389/fnut.2022.809058

. Mahmood, N., Muhoza, B., Kothakot, A., Munir, Z., Huang, Y., Zhang, Y., Pandiselvam, R., Iqbal, S., Zhang, S., Li, Y. (2023). Application of emerging thermal and nonthermal technologies for improving textural properties of food grains: A critical review. Comprehensive Reviews in Food Science and Food Safety, 23(1). https://doi.org/10.1111/1541-4337.13286

. Lara, L. M., Wilson, S. A., Chen, P., Atungulu, G. G. (2019). The effects of infrared treatment on physicochemical characteristics of vegetable soybean. Heliyon, 5(1), e01148. https://doi.org/10.1016/j.heliyon.2019.e01148

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).