SEPARATION OF NATIVE NANO-DISPERSE CLAY SORBENT SUSPENSION BY FLOCCULATION AND SEDIMENTATION

DOI:

https://doi.org/10.15421/jchemtech.v33i4.334859Keywords:

clay suspensions; flocculation; sedimentation; separation.Abstract

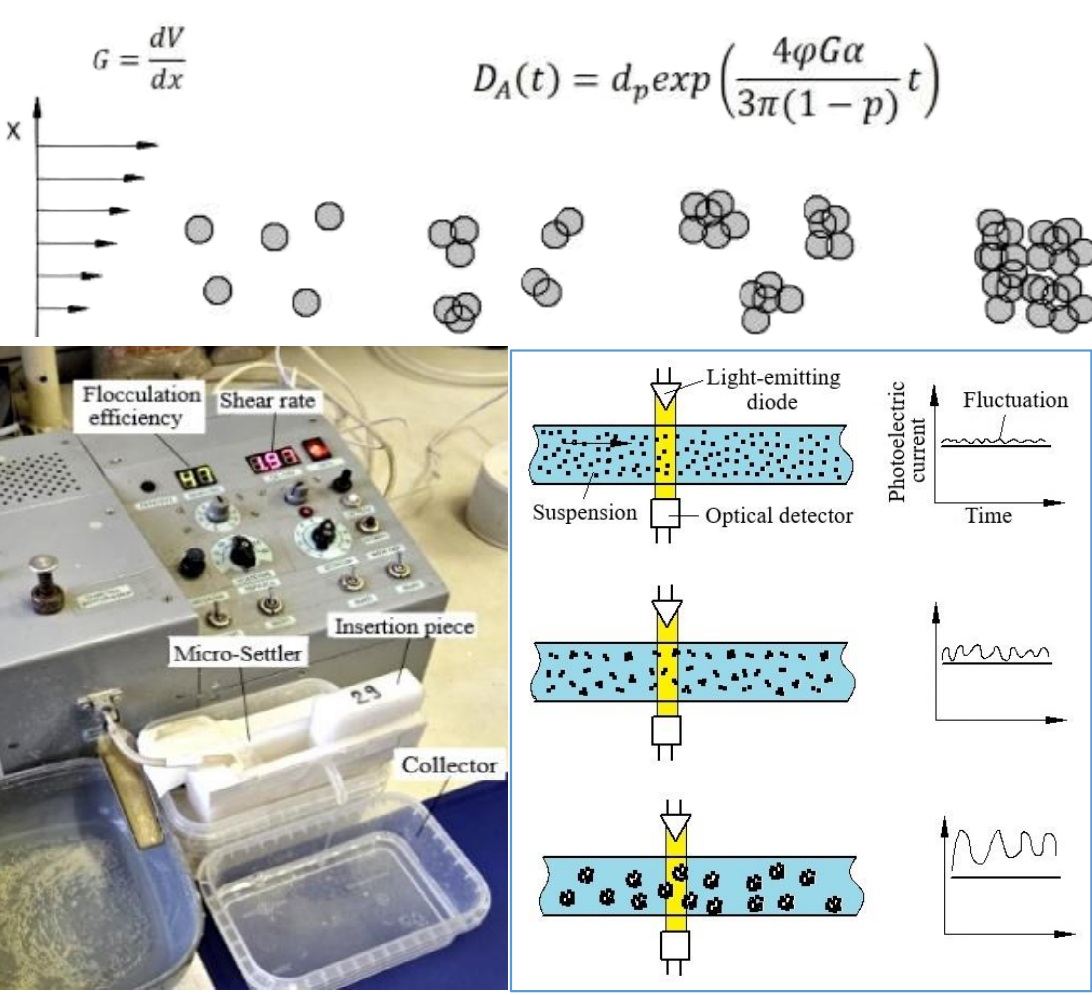

The growth of industrial and agricultural production inevitably leads to an increase in freshwater deficiency, and this is indeed observed on all continents of our planet. The only way to overcome this challenging problem is to develop effective methods for purifying circulating water from dispersed and soluble substances, including heavy metal ions and water-soluble components petroleum products (Toluene, Benzene, Phenol, and similar ones.) It is generally recognised that the simplest, most accessible, and cheapest way to purify water from soluble contaminants is the use of ultrafine clay sorbents. Studies on the process of separating clay suspensions have been conducted using samples of clays mined from deposits in Ukraine. The samples were treated with anionic flocculants. The effectiveness of flocculants, their optimal dose, and the optimal medium shear rate in the flocculator were defined using the device UltraFloc-Tester “UFT-TFS-029”. It was found that, depending on the properties of the clay, the treatment of the clay suspension (3 g/l) for 6 seconds in a flocculator at a medium shear rate of 1000–1500 s-1 followed by subsequent separation in a flow-through horizontal micro-settler for 55 seconds, allowed to achieve the residual suspension concentration around 0.18–0.42 g/l. Additionally, it has been found that Magnafloc 5250 can be regarded as the most effective and commonly used all-purpose flocculant for the studied clay suspensions.

References

Jun, B.-M., Al-Hamadani, Y.A.J., Son, A., Park, C.M., Jang, M., Jang, A., Kim, N.C., Yoon, Y. (2020). Applications of metal–organic framework based membranes in water purification: A review. Sep. Purif. Technol., 247, 116947. https://doi.org/10.1016/j.seppur.2020.116947

Askalany, A., Ali, E.S., Mohammed, R.H. (2020). A novel cycle for adsorption desalination system with two stages ejector for higher water production and efficiency. Desalination, 496, 114753. https://doi.org/10.1016/j.desal.2020.114753

Rahmani, S., Zeynizadeh, B., Karami, S. (2020). Removal of cationic methylene blue dye using magnetic and anionic–cationic modified montmorillonite: Kinetic, isotherm and thermodynamic studies. Appl. Clay Sci., 184, 105391.

https://doi.org/10.1016/j.clay.2019.105391

Khodabakhshloo, N., Biswas, B., Moore, F., Du, J., Naidu, R. (2021). Organically functionalized bentonite for the removal of perfluorooctane sulfonate, phenanthrene and copper mixtures from wastewater. Appl. Clay Sci., 200, 105883.

https://doi.org/10.1016/j.clay.2020.105883

Combatt, M.P.M., Amorim, W.C.S., Brito, E.M.D.S., Cupertino, A.F., Mendonça, R.C.S., Pereira, H.A. (2020). Design of parallel plate electrocoagulation reactors supplied by photovoltaic system applied to water treatment. Comput. Electron. Agric., 177, 105676. https://doi.org/10.1016/j.compag.2020.105676

Wang, J., Tang, X., Xu, Y., Cheng, X., Li, G., Liang, H. (2020). Hybrid UF/NF process treating secondary effluent of wastewater treatment plants for potable water reuse: Adsorption vs. coagulation for removal improvements and membrane fouling alleviation. Environ. Res., 188, 109833. https://doi.org/10.1016/j.envres.2020.109833

Ozbey-Unal, B., Omwene, P.I., Yagcioglu, M., Balcik-Canbolat, Ç., Karagunduz, A., Keskinler, B., Dizge, N. (2020). Treatment of organized industrial zone wastewater by microfiltration/reverse osmosis membrane process for water recovery: From lab to pilot scale. J. Water Process Eng., 38, 101646. https://doi.org/10.1016/j.jwpe.2020.101646

Saleh, I.A., Zouari, N., Al-Ghouti, M.A. (2020). Removal of pesticides from water and wastewater: Chemical, physical and biological treatment approaches. Environ. Technol. Innov., 19, 101026.

https://doi.org/10.1016/j.eti.2020.101026

Yu, F., Bai, X., Liang, M., Ma, J. (2021). Recent progress on metal–organic framework-derived porous carbon and its composite for pollutant adsorption from liquid phase. Chem. Eng. J., 405, 126960.

https://doi.org/10.1016/j.cej.2020.126960

Ewis, D., Ba-Abbad, M.M., Benamor, A., El-Naas, M.H. (2022). Adsorption of organic water pollutants by clays and clay minerals composites: A comprehensive review. Appl. Clay Sci., 229, 105401.

https://doi.org/10.1016/j.clay.2022.106686

Khan, S., Ajmal, S., Hussain, T., Rahman, M. (2023). Clay-based materials for enhanced water treatment: Adsorption mechanisms, challenges, and future directions. J. Umm Al-Qura Univ. Appl. Sci., Online first. doi: 10.1007/s43994-023-00083-0

Ozola, R., Krauklis, A., Burlakovs, J., Klavins, M., Vincevica-Gaile, Z., Hogland, W. (2019). Surfactant-modified clay sorbents for the removal of p-nitrophenol. Clays Clay Miner., 67(2), 132–141.

https://doi.org/10.1007/s42860-019-00015-2

Yerbolov, S., Daumova, G. (2022). Wastewater purification from metal ions by ultra-dispersed natural sorbents. J. Ecol. Eng., 23(1), 43–51. https://doi.org/10.12911/22998993/143867

Rulyov, N.N., Dontsova, T.A., Korolyov, V.Ya. (2007). Separation of fine disperse sorbent from purified water by ultra-flocculation and turbulent micro-flotation. Int. J. Environ. Pollut., 30(2), 341–352.

Rulyov, N.N., Maes, A., Korolyov, V.J. (2000). Optimization of hydrodynamic treatment regime in the processes of sorption–flocculation water purification from organic contaminants. Colloids Surf. A, 175(3), 371–381.

Rulyov, N.N., Dontsova, T.A., Korolyov, V.Ja. (2005). Ultra-flocculation of diluted fine disperse suspensions. Miner. Process. Extr. Metall. Rev., 26(3–4), 203–215.

Concha, F., Rulyov, N.N., Laskowski, J.S. (2012). Settling velocities of particulate systems 18: Solid flux density determination by ultra-flocculation. Int. J. Miner. Process., 104–105, 53–58.

Rulyov, N.N., Laskowski, J.S., Concha, F. (2011). The use of ultra-flocculation in optimization of the experimental flocculation procedures. Physicochem. Probl. Miner. Process., 46, 5–14.

Gregory, J., Nelson, D.W. (1986). Monitoring of aggregates in flowing suspensions. Colloids Surf., 18(2–4), 175–188.

Shakeel, A., Safar, Z., Ibanez, M., Van Paassen, L., Chassagne, C. (2020). Flocculation of clay suspensions by anionic and cationic polyelectrolytes: A systematic analysis. Minerals, 10(11), 1013.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).