CHARACTERIZATION OF LIGNOCELLULOSIC BIOMASS COMPLEX FOR UNLOCKING THE POTENTIAL OF SUSTAINABLE BIOFUEL PRODUCTION

DOI:

https://doi.org/10.15421/jchemtech.v33i4.338104Keywords:

biomass valorization, biofuel, bioethanol, cellulose, pretreatment, agricultural residuesAbstract

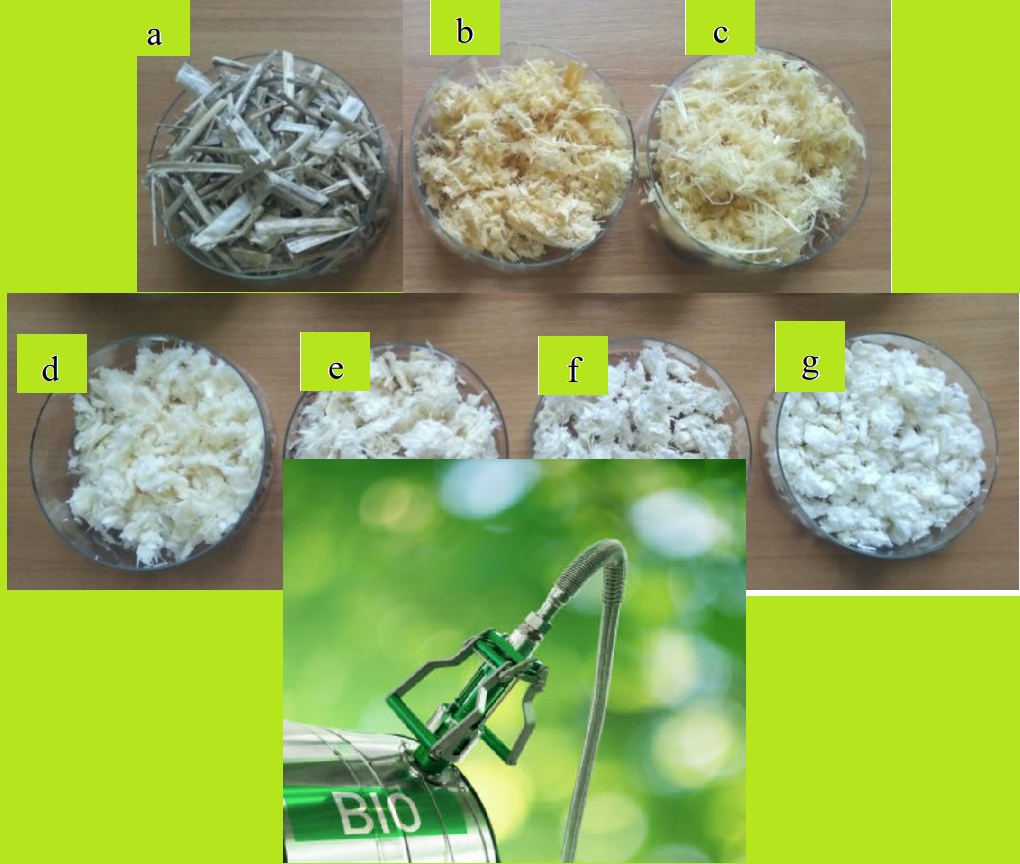

The present study investigates the chemical composition and delignification efficiency of various lignocellulosic biomass types as feedstock for bioethanol production. Agricultural residues and dedicated energy crops were identified as the most promising substrates due to their high cellulose (exceeding 40 %) and hemicellulose content (20–28 %), which are crucial for fermentable sugar yield. Non-fibrous biomass with higher lignin content, such as apricot and walnut shells (43–44 % lignin), exhibited structural resistance that hinders the effectiveness of pretreatment. Peracetic acid pretreatment was applied as a selective delignification method, demonstrating significant lignin removal while minimizing polysaccharide degradation. The optimal duration of pretreatment was established to be between 90 and 120 minutes, which provides a balance between preserving substrate yield and maximizing lignin reduction. Despite diffusion limitations in shell biomass, leading to higher residual lignin content, these substrates retained a significant proportion of polysaccharides, highlighting their potential for further use after process optimization. The findings provide critical insights into biomass-specific pretreatment strategies, facilitating enhanced enzymatic hydrolysis and subsequent biochemical conversion to bioethanol.

References

Ang, T. Z., Salem, M., Kamarol, M., Das, H. S., Nazari, M. A., Prabaharan, N. (2022). A Comprehensive Study of Renewable Energy Sources: Classifications, Challenges and Suggestions. Energy Strategy Reviews, 43, 100939. https://doi.org/10.1016/j.esr.2022.100939

Panwar, N. L., Kaushik, S. C., Kothari, S. (2011). Role of Renewable Energy Sources in Environmental Protection: A Review. Renewable and Sustainable Energy Reviews, 15(3), 1513–1524. https://doi.org/10.1016/j.rser.2010.11.037

Hassan, M. H., Kalam, M. A. (2013). An Overview of Biofuel as a Renewable Energy Source: Development and Challenges. Procedia Engineering, 56, 39–53. https://doi.org/10.1016/j.proeng.2013.03.087

Cavelius, P., Engelhart-Straub, S., Mehlmer, N., Lercher, J., Awad, D., Brück, T. (2023). The Potential of Biofuels from First to Fourth Generation. PLOS Biology, 21(3), e3002063. https://doi.org/10.1371/journal.pbio.3002063

Moodley, P. (2021). Sustainable Biofuels: Opportunities and Challenges. In Sustainable Biofuels, 1–20. https://doi.org/10.1016/B978-0-12-820297-5.00003-7

Hirani, A. H., Javed, N., Asif, M., Basu, S. K., Kumar, A. (2018). A Review on First-and Second-Generation Biofuel Productions. In Biofuels: Greenhouse Gas Mitigation and Global Warming: Next Generation Biofuels and Role of Biotechnology, 141–154.

Deora, P. S., Verma, Y., Muhal, R. A., Goswami, C., Singh, T. (2022). Biofuels: An Alternative to Conventional Fuel and Energy Source. Materials Today: Proceedings, 48, 1178–1184. https://doi.org/10.1016/j.matpr.2021.08.227

Robak, K., & Balcerek, M. (2018). Review of Second Generation Bioethanol Production from Residual Biomass. Food Technology and Biotechnology, 56(2), 174. https://doi.org/10.17113/ftb.56.02.18.5428

Ghosh, S., Chowdhury, R., Bhattacharya, P. (2017). Sustainability of Cereal Straws for the Fermentative Production of Second Generation Biofuels. Applied Energy, 198, 284–298. https://doi.org/10.1016/j.apenergy.2016.12.091

Trembus, I., Hondovska, A., Halysh, V., Deykun, I., Cheropkina, R. (2022). Feasible Technology for Agricultural Residues Utilization for the Obtaining of Value-Added Products. Ecological Engineering & Environmental Technology, 23, 1–8. http://dx.doi.org/10.12912/27197050/145732

Halysh, V., Romero-García, J. M., Vidal, A. M., Kulik, T., Palianytsia, B., García, M., Castro, E. (2023). Apricot Seed Shells and Walnut Shells as Unconventional Sugars and Lignin Sources. Molecules, 28(3), 1455. https://doi.org/10.3390/molecules28031455

Rattanaporn, K., Roddecha, S., Sriariyanun, M., Cheenkachorn, K. (2017). Improving Saccharification of Oil Palm Shell by Acetic Acid Pretreatment for Biofuel Production. Energy Procedia, 141, 146–149. https://doi.org/10.1016/j.egypro.2017.11.027

Kim, J. S., Lee, Y. Y., Kim, T. H. (2016). A Review on Alkaline Pretreatment Technology for Bioconversion of Lignocellulosic Biomass. Bioresource Technology, 199, 42–48. https://doi.org/10.1016/j.biortech.2015.08.085

López-Linares, J. C., Ballesteros, I., Tourán, J., Cara, C., Castro, E., Ballesteros, M., Romero, I. (2015). Optimization of Uncatalyzed Steam Explosion Pretreatment of Rapeseed Straw for Biofuel Production. Bioresource Technology, 190, 97–105. https://doi.org/10.1016/j.biortech.2015.04.066

Mesa, L., González, E., Cara, C., González, M., Castro, E., Mussatto, S. I. (2011). The Effect of Organosolv Pretreatment Variables on Enzymatic Hydrolysis of Sugarcane Bagasse. Chemical Engineering Journal, 168(3), 1157–1162. https://doi.org/10.1016/j.cej.2011.02.003

Zhang, K., Pei, Z., Wang, D. (2016). Organic Solvent Pretreatment of Lignocellulosic Biomass for Biofuels and Biochemicals: A Review. Bioresource Technology, 199, 21–33. https://doi.org/10.1016/j.biortech.2015.08.102

Satari, B., Karimi, K., Kumar, R. (2019). Cellulose Solvent-Based Pretreatment for Enhanced Second-Generation Biofuel Production: A Review. Sustainable Energy & Fuels, 3(1), 11–62.

Technical Association of the Pulp and Paper Industry, (TAPPI). (2002). Acid–insoluble lignin in wood and pulp, T 222 om-02.

Technical Association of the Pulp and Paper Industry, (TAPPI), (2002). Ash in wood, pulp, paper and paperboard: combustion at 525°C, T 211 om-02.

Technical Association of the Pulp and Paper Industry, (TAPPI), 1997. Solvent extractives of wood and pulp, T 204 cm-97.

Technical Association of the Pulp and Paper Industry, (TAPPI), 2002. One percent sodium hydroxide solubility of wood and pulp, T 212 om-02.

Kurschner, K., Hoffer, A. (1931). A New Quantitative Cellulose Determination. Chemische Zeitung, 55, 1811.

Wise, L. E., Merphy, M., D’Addieco, A. A. (1946). Chlorite Holocellulose, Its Fraction and Bearing on Summative Wood Analysis and on Studies on the Hemicelluloses. Paper Trade Journal, 122, 35–43.

Barbash, V. A., Galysh, V. V., Deykun, I. M. (2022). Influence of Peracetic Delignification on the Lignocellulosic Complex of Biomass. Issues of Chemistry and Technical Technology, (4), 3–10. https://doi.org/10.32737/0021-8688-2022-4-3-10

Yuan, Y., Jiang, B., Chen, H., Wu, W., Wu, S., Jin, Y., Xiao, H. (2021). Recent Advances in Understanding the Effects of Lignin Structural Characteristics on Enzymatic Hydrolysis. Biotechnology for Biofuels, 14, 205. https://doi.org/10.1186/s13068-021-02054-1

Wu, X., Tang, W., Huang, C., Huang, C., Lai, C., & Yong, Q. (2019). The Effects of Exogenous Ash on the Autohydrolysis and Enzymatic Hydrolysis of Wheat Straw. Bioresource Technology, 286, 121411. https://doi.org/10.1016/j.biortech.2019.121411

Ataie, F. F., & Riding, K. A. (2014). Impact of Pretreatments and Enzymatic Hydrolysis on Agricultural Residue Ash Suitability for Concrete. Construction and Building Materials, 58, 25–30. https://doi.org/10.1016/j.conbuildmat.2014.01.099

Fitria, Liu, J., Yang, B. (2023). Roles of Mineral Matter in Biomass Processing to Biofuels. Biofuels, Bioproducts and Biorefining, 17(3), 696–717. https://doi.org/10.1002/bbb.2468

Peciulyte, A., Karlström, K., Larsson, P. T., Olsson, L. (2015). Impact of the Supramolecular Structure of Cellulose on the Efficiency of Enzymatic Hydrolysis. Biotechnology for Biofuels, 8, 1–13.

Ling, Z., Chen, S., Zhang, X., Xu, F. (2017). Exploring Crystalline-Structural Variations of Cellulose during Alkaline Pretreatment for Enhanced Enzymatic Hydrolysis. Bioresource Technology, 224, 611–617. https://doi.org/10.1016/j.biortech.2016.10.064

Ling, Z., Chen, S., Zhang, X., Takabe, K., Xu, F. (2017). Unraveling Variations of Crystalline Cellulose Induced by Ionic Liquid and Their Effects on Enzymatic Hydrolysis. Scientific Reports, 7(1), 10230. https://doi.org/10.1038/s41598-017-09885-9

Sun, S. F., Yang, H. Y., Yang, J., Shi, Z. J. (2022). The Effect of Alkaline Extraction of Hemicellulose on Cocksfoot Grass Enzymatic Hydrolysis Recalcitrance. Industrial Crops and Products, 178, 114654. https://doi.org/10.1016/j.indcrop.2022.114654

Zhang, J., Wang, Y. H., Qu, Y. S., Wei, Q. Y., Li, H. Q. (2018). Effect of the Organizational Difference of Corn Stalk on Hemicellulose Extraction and Enzymatic Hydrolysis. Industrial Crops and Products, 112, 698–704. https://doi.org/10.1016/j.indcrop.2018.01.007

Kricka, W., Fitzpatrick, J., Bond, U. (2014). Metabolic Engineering of Yeasts by Heterologous Enzyme Production for Degradation of Cellulose and Hemicellulose from Biomass: A Perspective. Frontiers in Microbiology, 5, 174.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).