Synthesis of sulfur-containing lubricant additives on the basis of fatty acid ethyl esters

DOI:

https://doi.org/10.15421/081609Keywords:

synthesis, lubricant additives, fatty acid ethyl esters, organic polysulfanesAbstract

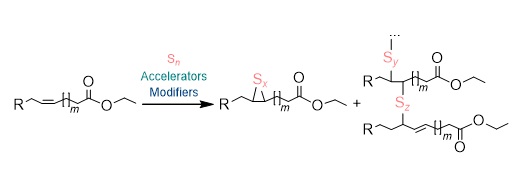

The study reveals an energy-, resource- and eco-friendly method for preparation of sulfur-containing lubricant additives via interaction of fatty acid ethyl esters of rapeseed oil with elemental sulfur. The structure of synthesized compounds under various reactants ratio (5–50 wt.% of sulfur), duration (30–240 min) and temperature of the process (160–215°С) was investigated using various analytical techniques. According to the established data, aside from addition to double bonds, the side reaction of hydrogen substitution at α-methylene groups near these bonds occurs and induces the formation of conjugated systems and chromophoric sulfur-rich derivatives. Also, we found that increase of process duration evokes growth of polysulfane chains, in contrast to the raise of temperature, which leads to the formation of sulfur-containing heterocycles and hydrogen sulfide, as a result of elimination. Influence of accelerators on sulfurization of fatty acid ethyl esters was also examined. The most effective among them are mixtures of zinc dibutyldithiocarbamate with zinc oxide or stearic acid, which soften synthesis conditions and doubly decrease duration of the high-temperature stage. In addition, sulfur-containing compositions of ethyl esters and α-olefins, vulcanized esters by benzoyl peroxide, nonylphenols and zinc dinonylphenyldithiophosphate were designed. The study identified that lithium lubricant with sulfurized vulcanized esters provides improved tribological properties, in comparison with base lubricant or lubricant with the non-modified product.References

Rudnick, L. (2010). Lubricant Additives Chemistry and Application (Second edition). New York, USA: CRC Press.

Steudel, R. (2002). The Chemistry of Organic Polysulfanes R-Sn-R (n > 2). Chem. Rev., 102, 3905–3945. doi:10.1021/cr010127m CrossRef

Korff, J., & Cristano, A. (2000). Requirements for Environmentally Acceptable Greases According to «Blue Angel Regulation». NLGI Spokesman, 64(8), 22–29.

Torbacke, M., Rudolphi, A. K., & Kassfeldt, E. (2014). Lubricants: Introduction to Properties and Performance. Chichester, United Kigdom: Wiley.

Mortier, R. M., Fox, M. F., & Orszulik, S. T. (Eds.) (2010). Chemistry and Technology of Lubricants (Third Edition). Dordrecht, Heidelberg, London, New York: Springer. doi:10.1007/978-1-4020-8662-5 CrossRef

Biglova, R. Z., Talipov, R. F., & Galimzyanova, A. U. (2008). Products of Reaction of the Piperylene Fraction with Elemental Sulfur as Additives to Lubricating Oils. Russ. J. Appl. Chem., 81(3), 443–447. doi:10.1134/S1070427208030191 CrossRef

Popov, Yu. V., Uskach, Ya. L., Ledenyov, S. M., Kroman, D. A., & Pavlova, V. A. (2013). Synthesis of a Sulfur-Containing Additive to Transmission Lubricants Based on the С20–С26 Fraction of α-Olefins. Russ. J. Appl. Chem., 86(3), 479–481. doi:10.1134/S1070427213030257 CrossRef

Popov, Yu. V., Uskach, Ya. L., Ledenyov, S. M., Tokmacheva, N. Yu., & Dontsovav, O. N. (2014). High-Sulfur Additive for Transmission Oils. Chem. Technol. Fuels Oils, 50(3), 202–206. doi:10.1007/s10553-014-0509-1 CrossRef

Ledenyov, S. M., Popov, Yu. V., Kroman, D. A. & Pavlova, V. A. (2015). Catalytic Sulfidation of C12–C14 α-Olefin Fractions. Chem. Technol. Fuels Oils, 51(5), 454–457. doi:10.1007/s10553-015-0624-7 CrossRef

Pop, G. S., Bodachivskyi, I. S., Bodachivska, L. I., Kukhar, V. P., Patriliak, K. I, & Okhrimenko, M. V. (2014). Ukraine Patent No. 106566. Kyiv, Ukraine. BPCI NAS of Ukraine.

Bodachivskyi, Yu. S., & Pop, G. S. (2014). Synthesis and Structure of Sulfur-Containing Antifriction Additives for Lubricants. Katal. Neftehim., 23, 15–20.

Sirenko, H. A., Kuzyshyn, O. V., & Lytvyn, B. L. (2009). [Influence of Sulfidizing Catalyst on Loading Capacity of Lubricating Nanofilms of Rape Oil on Metal Sufaces]. Phys. Chem. Solid State, 1(10), 189–192 (in Ukrainian).

Pretsch, E., Bühlman, P., & Badertscher, M. (2009). Structure Determination of Organic Compound. Berlin, Germany: Springer.

Wunderlich, B. (2005). Thermal Analysis of Polymeric Materials. Berlin, Germany: Springer.

Bodachivskyi, Yu. S., Pop, G. S., & Rogalskyi, S. P. (2015). [Effect of Accelerants on Oil’s Fatty Acid Esters Sulfurization]. Katal. Neftehim., 24, 41–46 (in Ukrainian).

Sulfur Petroleum Extreme Pressure Additives. Retrieved from dic-global.com

Downloads

Published

Issue

Section

License

Copyright (c) 2016 Oles Honchar Dnipropetrovsk National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).