INFLUENCE OF THE COMPOSITION OF MODIFIED LIGNIN-EPOXY COATING ON CORROSION RESISTANCE USING RESPONSE SURFACE METHODOLOGY

DOI:

https://doi.org/10.15421/jchemtech.v31i4.290101Keywords:

APTES; Box–Behnken design model; BPA-EC; carbon steel; lignin; organic coating.Abstract

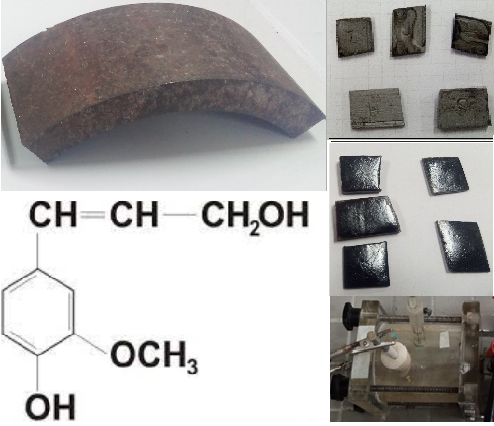

Bisphenol A epichlorohydrin (BPA-EC) as a resin, and cycloaliphatic amine (CAA) as a curing agent, are conventionally used for formulating epoxy coatings for industrial applications. However, due to its noticeable toxicity, alternative curing agents such as aminopropyl triethoxysilane (APTES) can be used instead of CAA. Moreover, BPA-EC can be partially replaced by kraft lignin. In this study, the influences of APTES, BPA-EC, and kraft lignin on corrosion resistance were analyzed using the robust statistical analytical capabilities of the existing optimization models. Response surface methodology and the Box–Behnken design model were used to investigate the respective and cumulative effect of each element. Initially, the model has a P value of 0.0037, with some of the terms not significant. Thus, a modified model has been introduced keeping only the significant terms. Finally, a P-value of 0.0004 has been achieved. Although the model showed a non-linear association for all the constituent elements, no cumulative relation has been found. However, statistics showed that BPA-EC is a necessary element for the coating to be corrosion-resistive, as corrosion resistance of the coating is proportional to the quantity of BPA-EC in the coating. Thus, the study concludes that in an attempt to decrease toxicity from the proposed APTES-cured coating matrix, BPA-EC cannot be completely replaced by lignin.

References

Harb, S. V., Cerrutti, B. M., Pulcinelli, S. H., Santilli, C. V., Hammer, P. (2015). Siloxane–PMMA hybrid anti-corrosion coatings reinforced by lignin, Surf. Coatings Technol., 275, 9–16. https://doi.org/10.1016/j.surfcoat.2015.05.002.

Figueiredo, P., Lintinen, K., Hirvonen, J. T., Kostiainen, M. A. Santos, H. A. (2018). Properties and chemical modifications of lignin: Towards lignin-based nanomaterials for biomedical applications, Prog. Mater. Sci., 93, 233–269. https://doi.org/10.1016/j.pmatsci.2017.12.001.

Österberg, M., Sipponen, M. H., Mattos, B. D., Rojas, O. J. (2020). Spherical lignin particles: a review on their sustainability and applications, Green Chem., 22(9), 2712–2733. doi: 10.1039/D0GC00096E.

Dastpak A. (2018). From Waste to Valuable Resource: Lignin as a Sustainable Anti-Corrosion Coating, Coatings, 8(12), 454.

doi: 10.3390/coatings8120454.

Bio-based coating for wood outperforms traditional synthetic options. (2021). ScienceDaily. https://www.sciencedaily.com/releases/2021/07/210723105310.htm

Ur Rahman, O., Shi, S., Ding, J., Wang, D., Ahmad, S., Yu, H. (2018). Lignin nanoparticles: synthesis, characterization and corrosion protection performance, New J. Chem., 42(5), 3415–3425. doi: 10.1039/C7NJ04103A.

Zargarnezhad, H., Zarei, P., Wong, D., Lam, C. N. C., Asselin, E. (2023). Oxygen transport through epoxy-based powder coatings in humid environments, Prog. Org. Coatings, 175, 107295. https://doi.org/10.1016/j.porgcoat.2022.107295.

Hult, E.-L., Ropponen, J., Poppius-Levlin, K., Ohra-Aho, T., Tamminen, T. (2013). Enhancing the barrier properties of paper board by a novel lignin coating, Ind. Crops Prod., 50, 694–700. https://doi.org/10.1016/j.indcrop.2013.08.013.

Hao, C. (2019). A High-Lignin-Content, Removable, and Glycol-Assisted Repairable Coating Based on Dynamic Covalent Bonds, ChemSusChem, 12(5), 1049–1058. https://doi.org/10.1002/cssc.201802615.

Henn, K. A., Forsman, N., Zou, T., Österberg, M. (2021). Colloidal Lignin Particles and Epoxies for Bio-Based, Durable, and Multiresistant Nanostructured Coatings, ACS Appl. Mater. Interfaces, 13(29), 34793–34806. doi: 10.1021/acsami.1c06087.

Zhang, B., Yan, J., Xu, W., Yu, T., Chen, Z., Duan, J. (2022). Eco-Friendly Anticorrosion Superhydrophobic Al2O3@PDMS Coating With Salt Deliquescence Self-Coalescence Behaviors Under High Atmospheric Humidity, Frontiers in Materials, 9. https://doi.org/10.3389/fmats.2022.839948

Buchler SAFETY DATA SHEET. (2021). https://www.buehler.com/assets/SDS/UK/1350306_E_EpoxiCure-2-Resin_EN.PDF

COPPS. https://www.coppsindustries.com/wp-content/uploads/K-505-SDS.pdf

BASF, (2022). https://download.basf.com/p1/000000000030516237_SDS_CPA_TH/en_TH/Sharpen_000000000030516237_SDS_CPA_TH_en_1-0.pdf

An, L., Si, C., Bae, J. H., Jeong, H., Kim, Y. S. (2020). One-step silanization and amination of lignin and its adsorption of Congo red and Cu(II) ions in aqueous solution, Int. J. Biol. Macromol., 159, 222–230. https://doi.org/10.1016/j.ijbiomac.2020.05.072.

Ng, Q. Y., Low, J. H., Pang, M. M., Idumah, C. I. (2023). Properties Enhancement of Waterborne Polyurethane Bio-composite Films with 3-aminopropyltriethoxy Silane Functionalized Lignin, J. Polym. Environ., 31(2), 688–697. doi: 10.1007/s10924-022-02595-y.

Behin, J. Rajabi, L. Etesami, H., Nikafshar, S. (2018). Enhancing mechanical properties of epoxy resin using waste lignin and salicylate alumoxane nanoparticles, Korean J. Chem. Eng., 35(2), 602–612. doi: 10.1007/s11814-017-0301-0.

Liu, X., Chen, L., Liu, Z., Song, Q., Liu, C. (2021). Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings, Nanotechnology Reviews, 10(1), 1236–1252. doi: doi:10.1515/ntrev-2021-0078.

Devadasu, S., Bagale, U., Sonawane, S. H., Suranani, S. (2021). Development of ultra-high build self-healing coatings using amino silanized lignin nanocapsules, Mater. Today Proc., 45, 5745–5751. doi: https://doi.org/10.1016/j.matpr.2021.02.576.

Feldman, D., Banu, D., Natansohn, A., Wang, J. (1991). Structure–properties relations of thermally cured epoxy–lignin polyblends, J. Appl. Polym. Sci., 42(6), 1537–1550. https://doi.org/10.1002/app.1991.070420607.

Rezazad Gohari, A., Lamothe, S., Bilodeau, J.-P., Mansourian, A., Carter, A. (2023). Laboratory Study on Influence of Blending Conditions on Chemo-Thermal Characteristics of Lignin-Modified Bitumen, Applied Sciences, 13(13). doi: 10.3390/app13137766.

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).