DEVELOPMENT OF RESOURCE-SAVING TECHNOLOGY OF DYEING COTTON FABRICS BY REACTIVE DYES WITH REUSE OF TREATED WASTEWATER FROM DYEING AND FINISHING PRODUCTION AND CREATION OF A BASIC TECHNOLOGICAL SCHEME

DOI:

https://doi.org/10.15421/jchemtech.v32i3.299509Keywords:

dyeing and finishing industry, wastewate, adsorption, zeolite, reactive dyes, Coarse calico, dyeing, scheme.Abstract

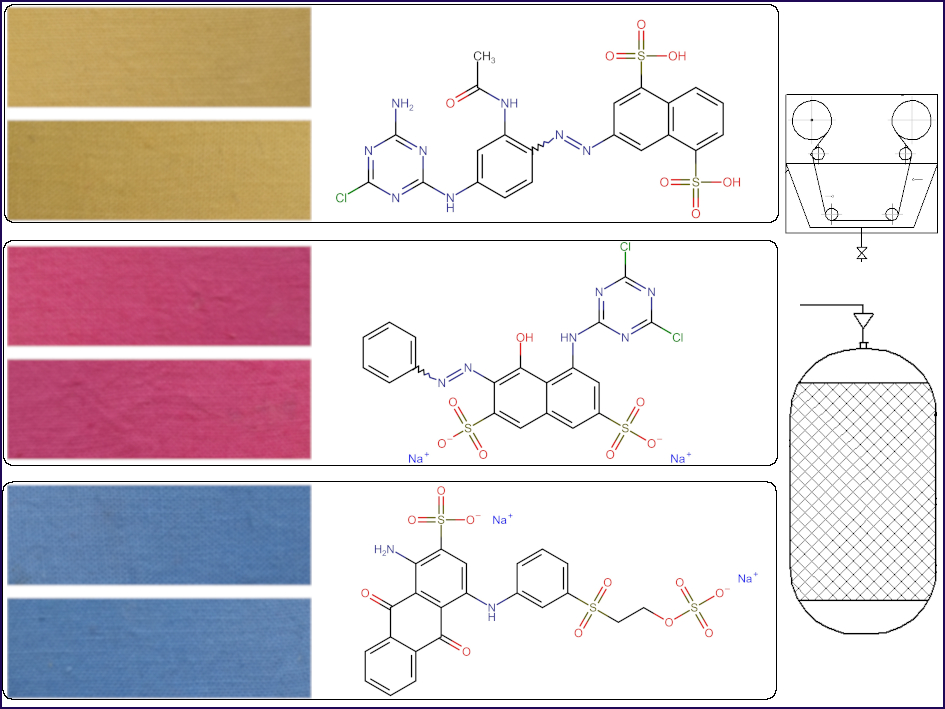

Consumption of water resources of the textile industry and the generation of large amounts of wastewater negative impact on the environmental ecosystem. The development of resource-saving technologies with the reuse of wastewater treated by adsorption method as a secondary resource in fabric dyeing technology is relevant. The work presents the results of the wastewater reuse treated with a natural zeolite sorbent during the cotton fabric Coarse calico (art. 3399) coloring with reactive dyes: Reactive Blue CB-RF, Reactive Red S-matrix, and Reactive Yellow S-3R. It was practically determined that using purified wastewater in the dyeing cotton fabric technology ensures the fabric coloring intensity 96–99 % compared to the standard (100 %). The obtained color’s stability is at the 4–5 points according to the «Gray standards scale». A series of experiments resulted in the possibility of using the doubly purified wastewater for dyeing cotton fabric with Reactive Blue CB-RF and Reactive Red S-matrix dyes to get a hue within 96 %. The color difference of all examined fabric samples (DE < 2) (when comparing between reference and dyed samples). Thus, the principle diagram of dyeing cotton fabric with reactive dyes and the repeated use of wastewater purified by the adsorption method has been developed. Dyeing according to this scheme has been tested in the production conditions of the Private Joint Stock Company Cherkasy Silk Plant (PJSC CSP) (Cherkasy, Ukraine). The expense of water treatment is calculated by comparing the costs of the water softening process and cleaning wastewater with a zeolite sorbent for its reuse. Cost savings of 10%. The spectrophotometric method was used in the work. The dyeing stability was determined according to Ukraine’s current state and international ISO standards. The Python programming language, engineering, and scientific data visualization libraries Matplotlib and Seaborn were used to visualize the experimental data.

References

Paździor, K., Bilińska, L., Ledakowicz, S. (2019). A review of the existing and emerging technologies in the combination of AOPs and biological processes in industrial textile wastewater treatment. Chemical Engineering Journal, 376, 120–147 https://doi.org/10.1016/j.cej.2018.12.057

Periyasamy, A.P., Militky, J. (2020). Sustainability in Textile Dyeing: Recent Developments. Part of the Sustainable Textiles: Production, Processing, Manufacturing & Chemistry, 37–79.

Marszałek, J., Żyłła, R. (2021). Recovery of Water from Textile Dyeing Using Membrane Filtration Processes. Processes, 9(10), 18–33, https://doi.org/10.3390/pr9101833.

Vajnhandl, S., Valh, J.V. (2014). The status of water reuse in european textile sector. Journal of environmental management. 141, 29–35. https://doi.org/10.1016/j.jenvman.2014.03.014

Silva, L.G., Moreira, F.C., Souza, A.A., Souza, S.M., Boaventura, R.A., Vilar, V.J. (2018). Chemical and electrochemical advanced oxidation processes as a polishing step for textile wastewater treatment: A study regarding the discharge into the environment and the reuse in the textile industry. Journal of Cleaner Production. 198, 430–442. https://doi.org/10.1016/j.jclepro.2018.07.001

Chen, H., Yu, X., Wang, X., He, Y., Zhang, C., Xue, G., Liu, Z., Lao, H., Song, H., Chen W., Qian, Y., Zhang A., Li, X. (2021). Dyeing and finishing wastewater treatment in China: State of the art and perspective. Journal of Cleaner Production, 326, 129–353. https://doi.org/10.1016/j.jclepro.2021.129353.

Holkar, C.R., Jadhav, A.J., PinjarI, D.V., Mahamuni, N.M., Pandit, A.B. (2016). A critical review on textile wastewater treatments: possible approaches. Journal of environmental management, 182 351–366. https://doi.org/10.1016/J.JENVMAN.2016.07.090

Balcik-Canbolat, C. Sengezer, C., Sakar, H., Karagunduz, A., Keskinler, B. (2016). Recovery of real dye bath wastewater using integrated membrane process: Considering water recovery, membrane fouling and reuse potential of membranes. Environmental Technology, 38, 2668–2676. https://doi.org/10.1080/09593330.2016.1272641

Bilińska, L., Blus, K., Gmurek, M., Żyłła, R., Ledakowicz, S. (2019). Brine recycling from industrial textile wastewater treated by ozone. By-products accumulation. Part 2. Water 11(2), 233. https://doi.org/10.3390/w11020233.

Kaya, Y.; Barlas, H.; Arayici, S. (2009). Nanofiltration of Cleaning-in-Place (CIP) wastewater in a detergent plant: Effects of pH, temperature and transmembrane pressure on flux behavior. Separation and Purification Technology, 65, 117–129. https://doi.org/10.1016/j.seppur.2008.10.034

Yukseler, H., Uzal, N., Sahinkaya, E,; Kitis, M., Dilek, F.B., Yetis, U. (2017). Analysis of the best available techniques for wastewaters from a denim manufacturing textile mill. Journal of Environmental Management, 203, 1118–1125. https://doi.org/10.1016/j.jenvman.2017.03.04112.

Hu, Е., Shang, S., Tao, X., Jiang, S., Chiu, K. (2016). Regeneration and reuse of highly polluting textile dyeing effluents through catalytic ozonation with carbon aerogel catalysts. Journal of Cleaner Production, 137, 1055–1065. https://doi.org/10.1016/j.jclepro.2016.07.194

Oliinyk, H., S. (2005). Improving the efficiency of sulphur dyeing technology using treated wastewater: PhD thesis: 05.19.03. Kherson, 22p.

Pinto, C., Fernandes, A., Nunes, M. J., Baía, A., Ciríaco L., Pacheco, M.J. (2022). Reuse of Textile Dyeing Wastewater Treated by Electrooxidation. Water, 14(7), 33–54. https://doi.org/10.3390/w14071084

Natarajan, P., Karmegam, P.M., Madasamy, J. (2022). Effective treatment of domestic sewage to reuse in textile dyeing and catalytic treatment of generated dye wastewater. International Journal of Environmental Science and Technology, 20, 6209–6220. https://doi.org/10.1007/s13762-022-04275-9

Ćurić, I., Dolar, D., Bošnjak, J. (2021). Reuse of textile wastewater for dyeing cotton knitted fabric with hybrid treatment: Coagulation/sand filtration/UF/NF-RO. Journal of Environmental Management, 295, 113–133. https://doi.org/10.1016/j.jenvman.2021.113133

Molecular Weight to Size Calculator. https://nanocomposix.com/pages/molecular-weight-to -size-calculator

Kiron, M. I. (2021). Reactive Dyes: Classification, Dyeing Mechanism, Application & Stripping. https://textilelearner.net/reactive-dyes -classification-dyeing-mechanism/

Сhattopadhyay, d.p. (2011). chemistry of dyeing. handbook of textile and industrial dyeing. principles, processes and types of dyes, 1, 150–183. https://doi.org/10.1533/9780857093974.1.150

Reactive Blue 19. PubChem. https://pubchem.ncbi.nlm.nih.gov/compound/17409

Reactive Red 2. PubChem. https://pubchem.ncbi.nlm.nih.gov/compound/28781

Reactive Yellow 3. PubChem. https://pubchem.ncbi.nlm.nih.gov/compound/78686

Benjelloun, M., Miyah, Y., Evrendilek, G. A., Zerrouq, F., Lairini, S. (2021). Recent Advances in Adsorption Kinetic Models: Their Application to Dye Types. Arabian Journal of Chemistry, 14(4), 103031. https://doi.org/10.1016/j.arabjc.2021.103031

Yang, J., Wu, C., Fang, H., Chen, X., Lv, J. (2023). Exploring the requirements of reactive dyes in eco-friendly dyeing process: The relationship between dye structure, dyeing properties, and eco-friendly dyeing techniques. Dyes and Pigments, 223, 111976. https://doi.org/10.1016/j.dyepig.2024.111976

Semak Z.М. (1993). [Dyeing, printing, hand painting of fabrics]. Study guide, Kyiv: ISDO. (in Ukrainian).

Ahmed, I., Ahsan, M. L., Silva, A., Estrela, A. (2015). Reducing effluent pollution in dyeing cotton fabrics with reactive dyes. Spanish Journal of Industrial Chemistry and Textile Physics, 6(5), 50–57.

Calico is a fabric that has been tested for centuries. https://le-vele.com.ua/blog/byaz-eto-tkan-proverennaya-stoletiyami/.

Semak Z.M. (1996). Textile materials science (Fibres, yarns, threads). Study guide, Kyiv: ISDO. (in Ukrainian).

State Standard of Ukraine. Materials and products of textile, knitted, sewing and leather. Terms and definitions. (2001). (DSTU 3998-2000) http://online.budstandart.com/ru/catalog/document.html?iddoc=94911. Kyiv, Ukraine.

International Standard. Textile materials. Determination of colour fastness. Part X12. Method for determining the friction resistance of colouring. (2016) (DSTU ISO 105-Х12:2016)

International Organization for Standardization. Technical Committee ISO/TC 38, Textiles. Geneva, Switzerland

International Standard. Textile materials. Determination of colour fastness. Part A02. Grey scale for assessing colour change. (2005) (DSTU ISO 105 А02:2005)

ISO 11641:2012. Colour fastness tests. Colour fastness to sweating. https://www.iso.org/standard/54445.html

Koval, M.G. (2024). [Research of wastewater treatment of dying and finishing production by adsorbicial method using natural zeolite]. Scientific Notes of V.I. Vernadsky Taurida National University Series: Technical Sciences, 35(74), 1(2), 96–105. (in Ukrainian). https://doi.org/10.32782/2663-5941/2024.1.2/17

Olson, E.S. (1983). Textile Wet Processes. Noyes Publications, Park Ridge, N.J., USA.

Stolyarenko, G.S., Klymenko, T.V. (2010). Technology of water treatment: laboratory workshop for students of "Chemical Technology" of all forms of education. Cherkasy, ChSTU.

Koval, M.G., Konohrai, V.A., Feshchrnko, N.V., Romanenko, N.G., Yakymenko, I.K. (2023). Experimental evaluation of phytotoxicity of waste zeolite as a sorbent of wastewater from dyeing and finishing production by laboratory phytotesting. Science and Innovation. 6(19), 77–86, https://doi.org/10.15407/scine19.06.07.

Rabosh, I.O., Kofanova, O.V. (2019). [Evaluation of phytotoxicity of urban soils contaminated by road transport infrastructure]. Scientific reports of NULES of Ukraine. 1(77), 121–132. (in Ukrainian). https://doi.org/10.31548/dopovidi2019.01.003

Krainiukov, O.M., Kryvytska, I.A. (2017) Patent of Ukraine No. 113560. [Method for determining the degree of soil contamination]. Kyiv, Ukraine. Ukrainian Institute of Industrial Property. (in Ukrainian).

Sharma Gaurav, Bala Raja. (2003). Digital Color Imaging Handbook https://books.google.com.ua/books?id=OxlBqY67rl0C&pg=PA31&vq=1.42&dq=jnd+gaurav+sharma&source=gbs_search_s&sig=vresXi1emghh1Jq57hr2R6cVXIs&redir_esc=y#v=onepage&q=1.42&f=false ISBN 084930900X

Koval, M.G. (2022). [Planning and organisation of experimental studies of the cyclic use of resources in the technology of dyeing textile materials (on the example of dispersed dye dark blue Z)]. Scientific notes of Vernadsky TNU. Series: Technical sciences. 33(72), 6, 203–209. (in Ukrainian). https://doi.org/10.32782/2663-5941/2022.6/32

Koval, M., Romanenko, N. (2022). [Principle of wastewater reuse in the processes of dyeing textile materials]. Technical Sciences and Technologies, 4(30), 169–179. (in Ukrainian]. https://doi.org/10.25140/2411-5363-2022-4(30)-169-179

Koval, M., Kuzmenko, V. (2021). [Treatment of wastewater containing textile dyes by modified zeolite]. Fundamental and applied research in the modern world. Abstracts of VI International Scientific and Practical Conference Boston, 562–566. (in Ukrainian).

Koval, M., Golub, A. (2021). [Durability of dying of fabric dyed with Direct dyes using treated wastewater]. Integration of Education, Science and Business in the Modern Environment: Winter Debates: Abstracts of the II International Scientific and Practical Internet Conference, 1, 454–456. (in Ukrainian).

Koval, M. (2021). [Use of purified wastewater in the technology of fabric dying with Direct dyes]. Actual research in the modern world issue. 1(69), 165–169. (in Ukrainian).

Koval, M.G., Kuzmenko, V.G. (2022). Patent of Ukraine 151832 U. [Technological system of wastewater treatment complex for dyeing and finishing production with natural zeolite]. Kyiv, Ukraine. Ukrainian Institute of Industrial Property. (in Ukrainian).

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).