PROSPECTS OF USING DLP 3D PRINTING TECHNOLOGY TO PRODUCE MEMBRANE CERAMIC MODULES

DOI:

https://doi.org/10.15421/jchemtech.v33i2.317663Keywords:

3D printing, DLP technology, photopolymer resin, ceramic membranes, kaolin, membrane modulesAbstract

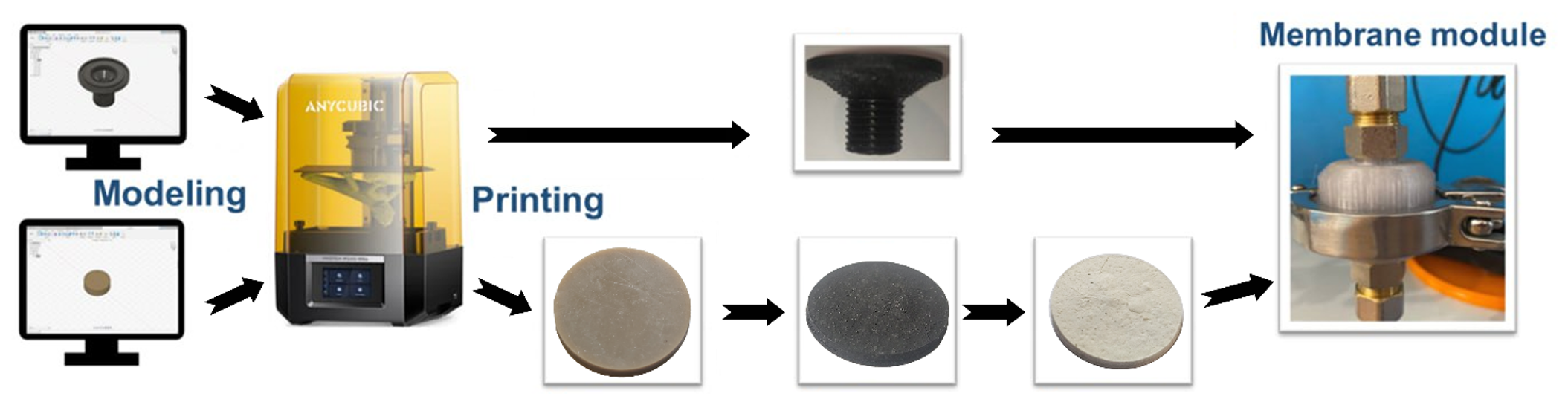

The ongoing evolution of 3D printing technologies demonstrates considerable potential for the production of porous ceramics, including ceramic matrices. These technologies enable the creation of three-dimensional structures with high complexity and precision from a variety of raw materials. This study assesses the feasibility of utilising DLP 3D printing technology to produce ceramic matrices and membrane holders for the development of ceramic membrane modules. To fabricate ceramic matrices by this method, it was proposed to use natural Ukrainian kaolin as the ceramic component in a photopolymer-based suspension. It was found that increasing the kaolin concentration (from 0–40 wt.%) in the suspension fed for 3D printing leads to an rise in viscosity, and with an increase in temperature at which the kaolin was pretreated prior to suspension preparation (0–600 °C), it decreases. The physicochemical processes occurring during kaolin heating were characterised by thermal analysis, infrared spectroscopy, and low-temperature nitrogen adsorption–desorption. The results demonstrate that heating kaolin above 450 °C triggers dehydroxylation, while heating to 640 °C leads to its transformation into metakaolinite. Consequently, the infrared bands corresponding to structural water disappear, and the specific surface area, determined using the BET model, decreases from 22.8 m2/g to 15.2 m2/g. The reduction in viscosity of the suspension with thermally treated kaolin is likely due to diminished interactions between kaolin particles and the photopolymer resin after structural water removal. Modelling and preparation for 3D printing of ceramic matrices and membrane holders were performed using Autodesk Fusion 360 and the Anycubic Photon Workshop slicing software. The results indicate that the DLP method produced structurally integral ceramic matrices and successfully printed membrane holders. Thus, DLP 3D printing technology offers significant prospects for fabricating tailored ceramic matrices and membrane holders.

References

Molchan, Y., Vorobyova, V., Pylypenko, I., Shtyka O., Maniecki, T., Dontsova, T. (2024). Physicochemical and antibacterial properties of ceramic membranes based on silicon carbide. Chem. Pap., 78(16), 8659–8672. doi: 10.1007/s11696-024-03695-w

Kuzminchuk, A., Burmak, A., Litynska, M., Dontsova, T. (2023). New diatomaceous earth and kaolinite ceramic membranes for turbidity reduction in water. Appl Nanosci, 13(7), 5335–5343. doi: 10.1007/s13204-023-02792-8

Lee, J.-Y., Tan W. S., An J., Chua C. K., Tang C. Y., Fane A.G., Chong T.H. (2016). The potential to enhance membrane module design with 3D printing technology. Journal of Membrane Science, 499, 480–490. doi: 10.1016/j.memsci.2015.11.008

Abdelkader, M., Petrik, S., Nestler, D., Fijalkowski, M. (2024). Ceramics 3D Printing: A Comprehensive Overview and Applications, with Brief Insights into Industry and Market. Ceramics, 7, 68–85. doi: 10.3390/ceramics7010006

Chen, T., Xu, P., Qiu, M., Chen, X., Zhong, Z., and Fan, Y. (2024). Construction of anti-fouling ceramic tubular membranes with corrugated inner surfaces using DLP 3D printing. Journal of Membrane Science, 706, 122941. doi: 10.1016/j.memsci.2024.122941

Diachenko, A.; Hutsul, K.; Dontsova, T. (2024). Prospects for Using 3d Printing to Form Ceramic Membranes: A Brief Review. Water Water Purif. Technol., Sci. Tech. News, 38(1), 14–26. doi: 10.20535/2218-930012024315361

Xing, J., Sun, W., Rana, R. S. (2013). 3D modeling and testing of transient temperature in selective laser sintering (SLS) process. Optik, 124(4), 301–304. doi: 10.1016/j.ijleo.2011.11.064

Lakhdar, Y., Tuck, C., Binner, J., Terry, A., and Goodridge, R. (2021). Additive manufacturing of advanced ceramic materials. Progress in Materials Science, 116, 100736.

doi: 10.1016/j.pmatsci.2020.100736

Chen, Z., Li, Z., Li, J., Liu, C., Lao, C., Fu, Y., Liu, C., Li, Y., Wang, P., He, Y. (2019). 3D printing of ceramics: A review. Journal of the European Ceramic Society, 39(4), 661–687. doi: 10.1016/j.jeurceramsoc.2018.11.013

Bai, Y., Williams, C. B. (2018). Binder jetting additive manufacturing with a particle-free metal ink as a binder precursor. Materials & Design, 147, 146–156. doi: 10.1016/j.matdes.2018.03.027

Hwa, L. C., Rajoo, S., Noor, A. M., Ahmad, N., Uday, M. B. (2017). Recent advances in 3D printing of porous ceramics: A review. Current Opinion in Solid State and Materials Science, 21(6), 323–347. doi: 10.1016/j.cossms.2017.08.002

Lakkala, P., Munnangi, S. R., Bandari, R., Repka, M. (2023). Additive manufacturing technologies with emphasis on stereolithography 3D printing in pharmaceutical and medical applications: A review. International Journal of Pharmaceutics: X(5), 100159. doi: 10.1016/j.ijpx.2023.100159

Tsolakis, I. A., Papaioannou, W., Papadopoulou, E., Dalampira, M., and Tsolakis, A. I. (2022). Comparison in terms of accuracy between DLP and LCD printing technology for dental model printing. Dentistry Journal, 10(10), 181. doi: 10.3390/dj10100181

Roohani, I., Entezari, A., Zreiqat, H. (2023). Liquid crystal display technique (LCD) for high resolution 3D printing of triply periodic minimal surface lattices bioceramics. Additive Manufacturing, 74, 103720. doi: 10.1016/j.addma.2023.103720

Schmidleithner, C., and Kalaskar, D. M. (2018). Stereolithography. In 3D Printing. IntechOpen. doi: 10.5772/intechopen.78147

Ye, Y., Du, Y., Hu, T., You, J., Bao, B., Wang, Y., Wang, T. (2021). 3D Printing of Integrated Ceramic Membranes by the DLP Method. Ind. Eng. Chem. Res., 60(26), 9368–9377. doi: 10.1021/acs.iecr.1c02224

Mamatha, S., Biswas, P., Johnson, R. (2023). Digital light processing of ceramics: an overview on process, materials and challenges. Prog Addit Manuf, 8(5), 1083–1102. doi: 10.1007/s40964-022-00379-3

Gao, Y., Jacques Lalevée, J., Simon-Masseron, A. (2023). An Overview on 3D Printing of Structured Porous Materials and Their Applications. Advanced Materials Technologies, 8(17), 2300377.

doi: 10.1002/admt.202300377

Zoumpouli, G. A., Guaraldo, T. T., Warren, Z., Mattia, D., Chew, J. (2024). Reimagining the shape of porous tubular ceramics using 3D printing. Applied Materials Today, 37, 102136. doi: 10.1016/j.apmt.2024.102136

Fu, Q., Ma, Y., Wang, J., Yang, Y., Wang, P., Li, S., Zhao, Y. (2024). Digital light processing of high-purity SiC ceramic membrane support modified by SiC whisker. Ceramics International, 50(21), Part A, 41237–41245. doi: 10.1016/j.ceramint.2024.07.435

Gu, Q., Wang, H., Gao, W., Yu, J., and Zhou, X. (2023). Preparation of large-size alumina ceramic parts by DLP 3D printing using high-solid-loading paste and optimizing the debinding process. Ceramics International, 49(17), Part B, 28801–28812. doi: 10.1016/j.ceramint.2023.06.142

Santoliquido, O., Camerota, F., Rosa, A., and Ortona, A. (2021). A novel device to simply 3D print bulk green ceramic components by stereolithography employing viscous slurries. Open Ceramics, 5, 100089. doi: 10.1016/j.oceram.2021.100089

Mastroianni, L., Russo, V., Eränen, K., Di Serio, M., Murzin, D. Y., and Salmi, T. (2024). Towards unconstrained catalyst shaping: high accuracy DLP printing of porous γ-Al2O3-based catalysts. Catal. Sci. Technol., 14(5), 1336–1348.

doi: 10.1039/D3CY01592K

Xu, X., Zhou, S., Wu, J., Zhang, C., and Liu, X. (2021). Inter-particle interactions of alumina powders in UV-curable suspensions for DLP stereolithography and its effect on rheology, solid loading, and self-leveling behavior. Journal of the European Ceramic Society, 41(4), 2763–2774.

doi: 10.1016/j.jeurceramsoc.2020.12.004

Molchan, Y., Bohdan, L., Kyrii, S., Tymoshenko, O., Pylypenko, I., Burmak, A., Vasyliev, G., Dontsova, T. (2025). Low-cost ceramic membrane supports based on Ukrainian kaolin and saponite. Functional Materials, 32(1), 87–96. doi: 10.15407/fm32.01.87

Sun, Q., Peng, Y., Cheng, H., Mou, Y., Chen, M. (2019). 3D printing of cavities in DPC ceramic substrates with kaolin pastes for hermetic packaging. 2019 20th International Conference on Electronic Packaging Technology (ICEPT), 1–4.

doi: 10.1109/ICEPT47577.2019.9081202

Revelo, C. F., Colorado, H. A. (2019). 3D printing of kaolinite clay with small additions of lime, fly ash and talc ceramic powders. Processing and Application of Ceramics, 13(3), 287–299. doi: 10.2298/PAC1903287R

Revelo, C. F., Colorado, H. A. (2018). 3D printing of kaolinite clay ceramics using the direct ink writing (DIW) technique. Ceramics International, 44(5), 5673–5682. doi: 10.1016/j.ceramint.2017.12.219

Hussain, M. I., Xia, M., Ren, X.-N., Ge, C., Zhao, Y., Shen, Z. (2024). High-precision printing of intricately shaped kaolin ceramics by digital light processing: Impact of solid content on microstructure and densification. Journal of Materials Research and Technology, 30, 2299–2310. doi: 10.1016/j.jmrt.2024.03.227

Ordoñez, E., Neves Monteiro, S., Colorado, H. A. (2022). Valorization of a hazardous waste with 3D-printing: Combination of kaolin clay and electric arc furnace dust from the steel making industry. Materials & Design, 217, 110617.

doi: 10.1016/j.matdes.2022.110617

Serhiienko, A. O., Dontsova, T. A., Yanushevska, O. I., Vorobyova, V. I., and Vasyliev, G. S. (2023). Characterization of ceramic membrane support based on Ukrainian kaolin. Molecular Crystals and Liquid Crystals, 752(1), 128–141.

doi: 10.1080/15421406.2022.2091279

Vovk, O.F., Davydova, M.Y., Yanushevska, O.I., Kyrii, S.O., Linovytska, V. M., Lapinskyi, A. V., Dontsova, T. A. (2024). Antibacterial properties of ceramic membranes with TiO2 selective layer. Journal of Chemistry and Technologies, 32(2), 351–362. https://doi.org/10.15421/jchemtech.v32i2.298738

Xu, X., Zhou, S., Wu, J., Zhang, C., Liu, X. (2020). Inter-particle interactions of alumina powders in UV-curable suspensions for DLP stereolithography and its effect on rheology, solid loading, and self-leveling behavior. Journal of the European Ceramic Society. doi: 10.1016/j.jeurceramsoc.2020.12.004

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).