DETERMINATION OF RATIONAL DRYING REGIMES OF TOMATO POMACE AND THEIR OPTIMAL POWDER FRACTION FOR FUNCTIONAL ENRICHMENT OF FOOD PRODUCTS WITH LYCOPENE

DOI:

https://doi.org/10.15421/jchemtech.v33i3.324647Keywords:

tomato pomace, lycopene, drying, grinding, tomato pomace powder, functional ingredientAbstract

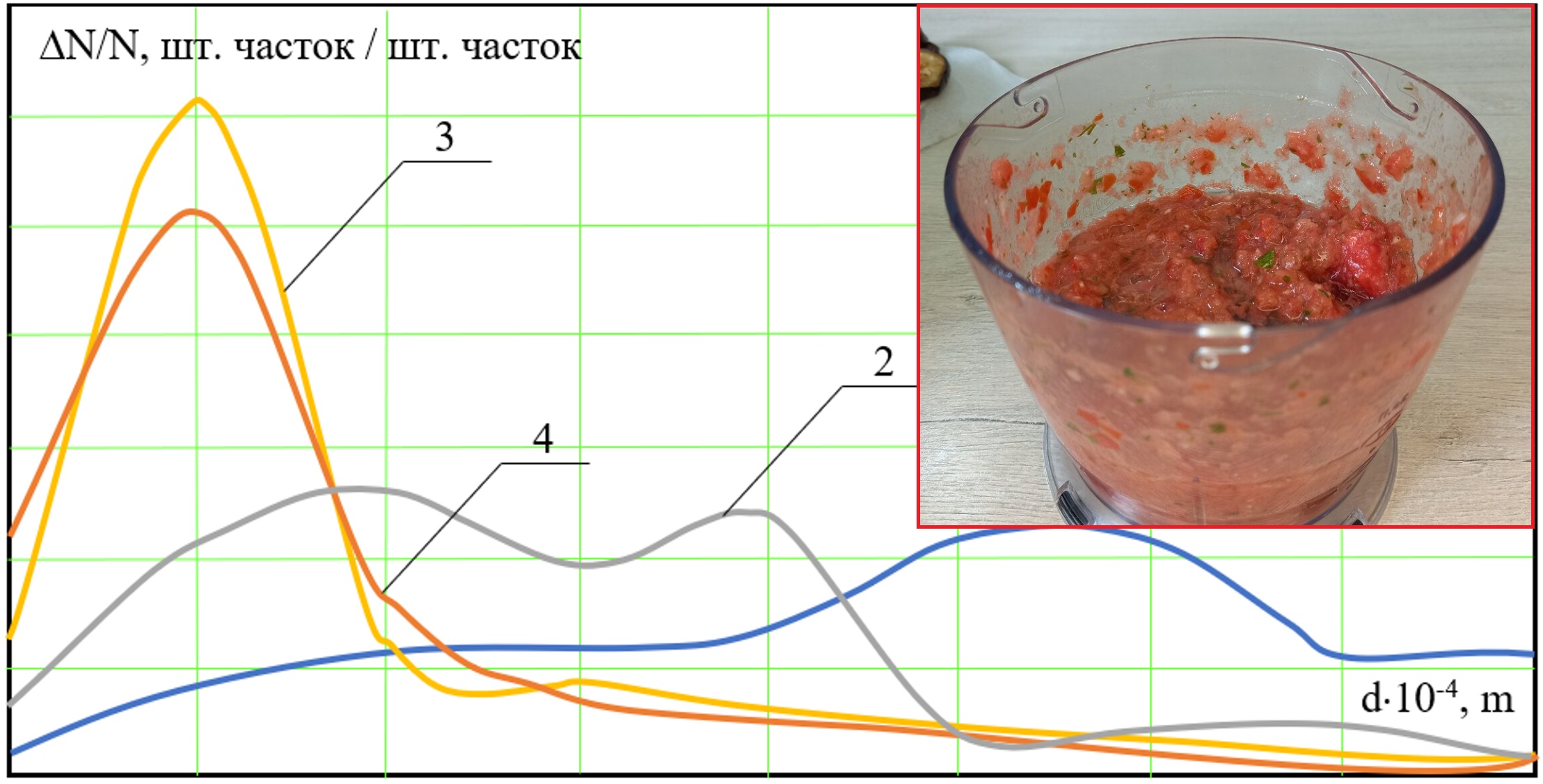

Based on the conducted research, the optimal drying modes of tomato pomace were selected, which fully meet the technological requirements. The dispersion of the powder obtained from dried tomato pomace was investigated and the particle size was determined. The optimal grinding modes of tomato pomace were established to obtain different powder fractions, which must be taken into account when obtaining them. It was established that tomato pomace powder has acceptable organoleptic indicators, and they are also a convenient commercial form that can be promising for a number of technologies in the food industry and restaurant catering establishments. In particular, as a functional ingredient for enriching food products with lycopene. The swelling of the powder obtained from dried tomato pomace was studied for different fractions (coarse, medium and fine fractions). The moisture-holding capacity of different fractions was determined and the moisture absorption coefficient was calculated. Based on experimental data, technological modes of the process of obtaining powder from tomato pomace were selected: drying at a temperature of 80 °C for 120 min., grinding duration 30 s, average particle size (30…50)·10–6 m.

References

Snezhkin, Yu. F., Shapar, R. O., Gusarova, O. V. (2021). [Reduced energy intensity of heat technologies in the production of dried products]. Energy and energy efficiency have been reinvented in the 21st century: materials of the XXII International Scientific and Practical Conference, 885–889. (In Ukrainian)

Snezhkin, Yu. F., Pazyuk, V. M., Petrova, Zh. O. (2021). [Improved energy efficiency of drying grain crops]. Energy and energy efficiency have been rediscovered in the 21st century: materials of the XXII International Scientific and Practical Conference, 860–864. (In Ukrainian)/

Snezhkin, Yu. F. (2022). [New technologies and methods of heat and power supply in municipal energy: Transcript of the speech at the meeting of the Presidium of the National Academy of Sciences of Ukraine on June 5, 2022]. Visnik Nacional Noi Academii Nauk Ukraini, (11), 46–53. (In Ukrainian) https://doi.org/10.15407/visn2022.11.046

Petrova, Zh.O., Pazyuk, V. M., Novikova, Y.P., Petrov, A. I. (2022). Research on the processing of peat into composite fuel. In M. S. Painted (Eds.), Sustainable Development: Environmental Protection. Energy saving. Balanced nature management: collective monograph.

Geletukha, G. G., Zheliezna, T. A., Kucheruk, P. P., Drahniev, S. V. (2023). Analysis of prospective directions for using Ukraine’s biomass potentional for energy. Thermophysics and Thermal Power Engineering, 45(2), 77–86. https://doi.org/10.31472/ttpe.2.2023.9

Petrova, Z., Sniezhkin, Y., Paziuk, V., Novikova, Y., Petrov, A. (2021). Investigation of the Kinetics of the Drying Process of Composite Pellets on a Convective Drying Stand. Journal of Ecological Engineering, 22(6), 159–166. https://doi.org/10.12911/22998993/137676

Kirilenko, O. V., Snezhkin, Yu. F., Basok, B.I., Bazeev, E.T. (2022). Energy of Ukraine: current scenarios for renewal and development.Visnik Nacional Noi Academii Nauk Ukraini, (9), 22–37. https://doi.org/10.15407/visn2022.09.022

National Council for the Recovery of Ukraine from the War. (2022). [Draft of the Post-War Recovery and Development Plan for Ukraine. Working group "Audit of losses incurred as a result of the war"]. (In Ukrainian). https://www.kmu.gov.ua/storage/app/sites/1/recoveryrada/ua/audit-of-war-damage.pdf

National Council for the Recovery of Ukraine from the War. (2022). [Draft of the Post-War Recovery and Development Plan for Ukraine. Working group "Energy security"]. (In Ukrainian). https://www.kmu.gov.ua/storage/app/sites/1/recoveryrada/ua/energy-security.pdf

Kushnir O.V. (2020) Action of phytohormone analogs and tebuconazole retardant in the growth process, morphogenesis and yield of sweet pepper: abstract... cand. Ph.D. S.-G. Sciences.

Yakushenko, E.N., Zhyla, V.I. (2024). The influence of the heat and mass transfer parameter on the average integral temperature during the drying process. Proceeding of the Conference. 53–59.

Yakushenko, E.N. (2014). [Improvement of energy efficiency in the process of drying grape peels in a mass exchange module with conductive heat input], abstract of... cand. tech. Sciences. (In Ukrainian).

[Preparation for the heating period under martial law.] (2022). USAID seminar materials. (In Ukrainian)

National Council for the Recovery of Ukraine from the War. (2022). [Draft of the Post-War Recovery and Development Plan for Ukraine. Working group "Construction, urban planning, modernization of cities and regions of Ukraine"]. (In Ukrainian) https://www.kmu.gov.ua/storage/app/sites/1/recoveryrada/ua/construction-urban-planning-modernization-of-cities-and-regions.pdf

Kyrylenko, O. V., Basok, B. I., Baseyev, Ye. T., Blinov, I. V. (2020). Power industry of Ukraine and realities of the global warming. Tekhnichna Elektrodynamika, (3), 52—61. https://doi.org/10.15407/techned2020.03.052

Basok, B. I., Butkevych, O. F., Dubovskyi, S. V. (2021). Technical and economic aspects of decarbonisation prospects assessing of the interconnected power system of Ukraine. Tekhnichna Elektrodynamika, (5), 55—62. https://doi.org/10.15407/techned2021.05.055

[Ministry for Communities and Territories Development of Ukraine]. (In Ukrainian)/ https://www.slideshare.net/rstofficial/ltrs10082022pdf

Blueprint for the Reconstruction of Ukraine. (2022). Centre for Economic Policy Research. London. https://cepr.org/about/news/blueprint-reconstruction-ukraine

Energy Efficiency 2021. (2021). IEA. https://iea.blob.core.windows.net/assets/9c30109f-38a7-4a0b-b159-47f00d65e5be/EnergyEfficiency2021.pdf

Basok, B. І., Bazyeev, Ye. Т., Kuraieva, І. В. (2021). Adaptation of municipal heat energy to climate change. Visn. Nac. Akad. Nauk Ukr., (4), 60—75. https://doi.org/10.15407/visn2021.04.060

Geyets, V. M., Kyrylenko, O. V., Basok, B. I., Baseyev, Ye. T. (2020). Energy Strategy: Projections (Review). Sci. Innov., 16(1), 3—14. https://doi.org/10.15407/scine16.01.003

Gusarova, O. V. (2020). [Intensification of heat and mass transfer during the consumption of apple chips], Abstract of the dissertation of a candidate of technical sciences, ITTF NASU. (In Ukrainian) https://doi.org/10.13140/RG.2.2.28554.08644

Snezhkin, Y., Petrova, Z., Paziuk, V., Telnikov, Y., Vyshnevskyi, V., Malaschyk, N. (2023). Energy-efficient chamber dryer with thick alloy heating elements. Energy Technologies & Resource Saving, 75(2), 85–95. https://doi.org/10.33070/etars.2.2023.07

Thamkaew, G., Sjцholm, I., Galindo, F. G. (2021). A review of drying methods for improving the quality of dried herbs. Critical Reviews in Food Science and Nutrition, 61(11), 1763–1786.

Nayak, P., Kumar, T., Gupta, A. K., Joshi, N. U. (2020). Peppermint a medicinal herb and treasure of health. Journal of Pharmacognosy and Phytochemistry, 1519–1528.

Nasr, A. (2020). Antioxidant Properties of Oven and Microwave Dried Ginger (Zingiberofficinale), Master's thesis, University. https://doi.org/10.13140/RG.2.

Galangal Root in the Carpathians http://karpatyua.org.ua/koren-kalgana-v-karpatax.htm (date of applying 02.02.21).

Lin, X., Xu, J.-L., Sun, D.-W. (2020). Evaluating drying feature differences between ginger slices and splits during microwave-vacuum drying by hyperspectral imaging technique. Food Chemistry, 332, 127407. https://doi.org/10.1016/j.foodchem.2020.127407

Namkanisorn, A., Murathathunyaluk, S. (2020). Sustainable drying of galangal through combination of low relative humidity, temperature and air velocity. Energy Reports, 6(2), 748–753. https://doi.org/10.1016/j.egyr.2019.11.150

Husarova, O., Shapar, R., Sorokova, N. (2020). Intensification of heat and mass transfer during the convective drying of apple to low final moisture. In Theoretical and Practical Aspects of the Development of the European Research Area. Riga, Latvia: Baltija Publishing. https://doi.org/10.30525/978-9934-588-53-2-52

Rudobashta, S. P., Kartashov, Й. M., Zueva, G. A. (2020). Mathematical modeling of the process of convective drying of materials taking into account their shrinkage. Journal of Engineering Physics and Thermophysics, 93(6), 1394–1401.

Avdieieva, L., Zhukotskyi, E., Dekusha, H., Ivanov, S. (2021). Analysis of the existing methods and specific features of drying shiitake mushrooms. Food Science and Technology, 15(3), 94–107. https://doi.org/10.15673/fst.v15i3.2118

Hu, L., Bi, J., Jin, X., Qiu, Y. (2021). Study on the rehydration quality improvement of shiitake mushroom by combined drying methods. Foods, 10, 769. https://doi.org/10.3390/foods10040769

Maftoonazad, N., Dehghani, M. R., Ramaswamy, H. S. (2022). Hybrid microwave-hot air tunnel drying of onion slices: Drying kinetics, energy efficiency, product rehydration, color, and flavor characteristics. Drying Technology, 40, 966–986. https://doi.org/10.1080/07373937.2020.1841790

Mierzwa, D., Szadzińska, J. (2023). An investigation of the use of microwaves and airborne ultrasound in the convective drying of Kale: Process efficiency and product characteristics. Sustainability, 15(23), 16200. https://doi.org/10.3390/su152316200

Subramaniam, S., Shunshun, J., Zhang, Z., Pu, J. (2021). Impact of post‐harvest processing or thermal dehydration on physiochemical, nutritional and sensory quality of shiitake mushrooms. Comprehensive Reviews in Food Science and Food Safety, 20, 2560–2595. https://doi.org/10.1111/1541-4337.12738

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Oles Honchar Dnipro National University

This work is licensed under a Creative Commons Attribution 4.0 International License.

- Authors reserve the right of attribution for the submitted manuscript, while transferring to the Journal the right to publish the article under the Creative Commons Attribution License. This license allows free distribution of the published work under the condition of proper attribution of the original authors and the initial publication source (i.e. the Journal)

- Authors have the right to enter into separate agreements for additional non-exclusive distribution of the work in the form it was published in the Journal (such as publishing the article on the institutional website or as a part of a monograph), provided the original publication in this Journal is properly referenced

- The Journal allows and encourages online publication of the manuscripts (such as on personal web pages), even when such a manuscript is still under editorial consideration, since it allows for a productive scientific discussion and better citation dynamics (see The Effect of Open Access).